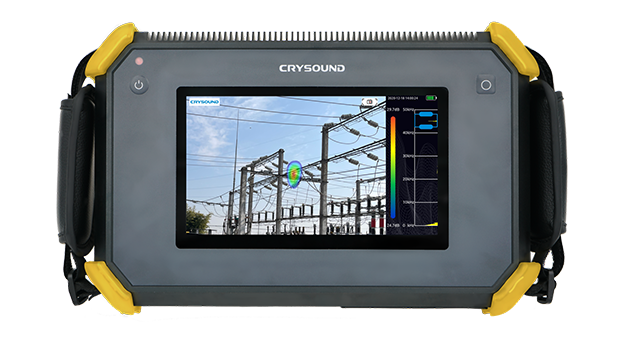

CRY2623M Fixed Acoustic Imager

CRY2623M Fixed Acoustic Imager uses microphone array beamforming technology to obtain sound source distribution data, and cooperates with high-definition cameras to capture video images in real time. It can help users realize remote monitoring system based onlocal network (LAN, etc.), wide area network (WAN, ADSL, 4G and private network, etc.), and help users realize industrial digital transformation, and support remote real-time monitoring of video images. As such, this provides facilities with further insight into product quality or safety issues, as well as the ability to rapidly detect them. Changes to compressors, pumps, pipes, cables, etc. can be understood in real time and in advance, rather than manually.

Features

128 digital MEMS microphones

24/7 Real-time monitoring

Small size easy to install

Early detection of equipment problems

Find faults that cannot be found

Factory automation product inspection & Alarms

Intelligent Inspection System

The CRY2623M can also be used as a payload for inspection, including UAV, robot, car or other mobile unit, Realizingmore intelligent inspection and monitoring applications.

Intelligent Inspection System

The CRY2623M can also be used as a payload for inspection, including UAV, robot, car or other mobile unit, Realizingmore intelligent inspection and monitoring applications.

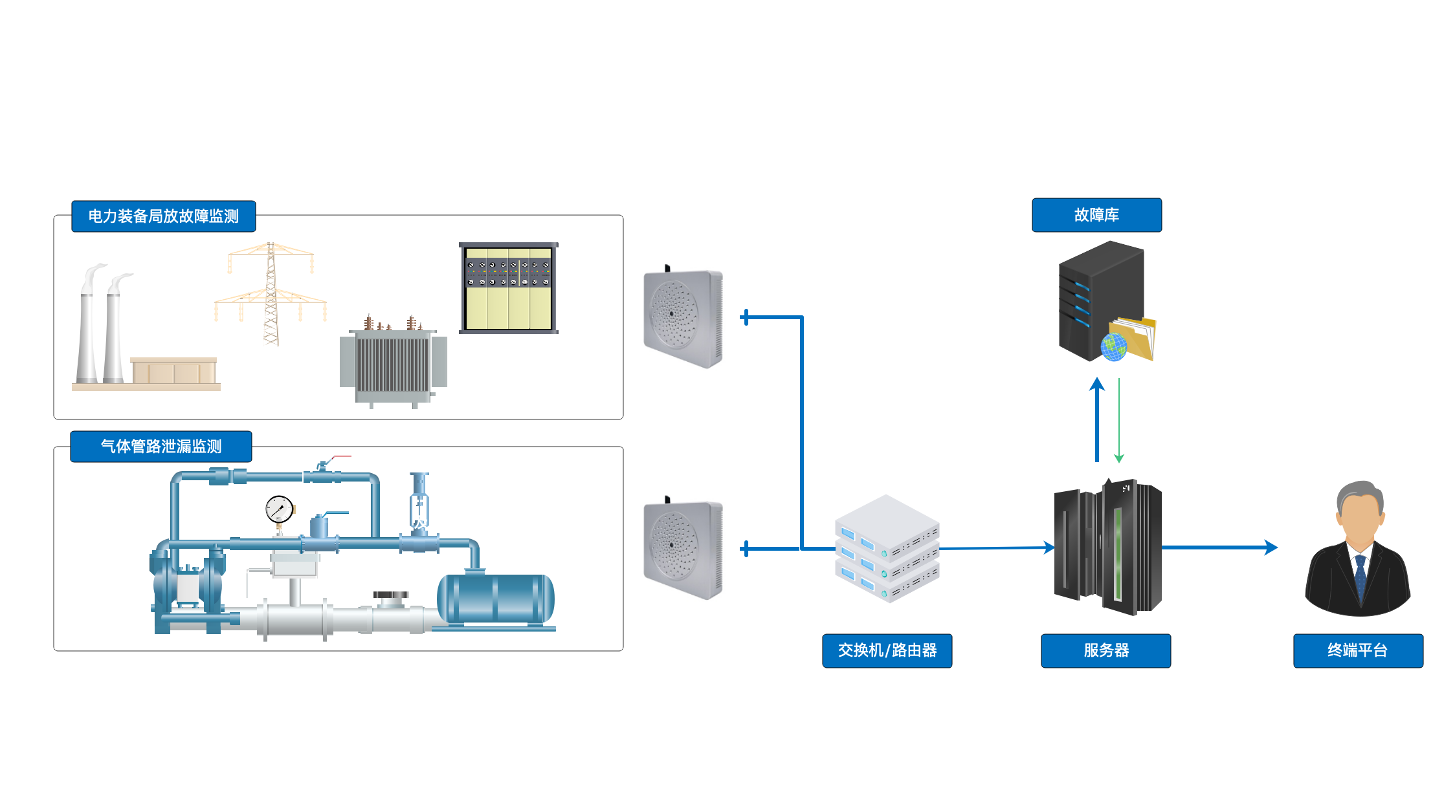

Online Monitoring System

Fix CRY2623M acoustic imaging module in certain key areas, and achieve a full range of 7X24 hour fault monitor and alarm. Give you real-time, accurate information about the status of your equipment and instant notification of equipment failures.

Usage Scenarios

Priority areas containing dangerous gases. Key areas with a high probability of fault in complex pipelines. Key areas for testing that are difficult for inspectors to reach.

Usage Scenarios

Priority areas containing dangerous gases. Key areas with a high probability of fault in complex pipelines. Key areas for testing that are difficult for inspectors to reach.

| Main Technical Specifications |

|---|

| Device Model | CRY2623M |

| Number of Microphone Channels | 128 channels |

| Test Frequency Range | 2kHz ~ 48kHz |

| Port | RJ45 |

| Data communication | RTSP/RTMP streaming transmission |

| Camera Resolution | 800W |

| Frame Rate | 25FPS |

| Test Distance | 0.5~50m |

| Weight | About 1.3kg |

| Size | 183mm X 169mm X 85.35mm |

| Storage | 8G internal storage, 64G TF card expansion storage |

| Operating Temperature | -10℃~+50℃ |

| Supply Voltage | DC12-20V |

| Power Consumption | About 14W |

| IP Degree of Protection | IP56 |

| Fixed way | Bottom 1/4 -20UNC thread/M5 screw fixing |

| Explosion-proof certification | CNEX |

| Intrisically Safe Power Supply |

|---|

| Intrinsically safe maximum open circuit voltage | DC 6.5V |

| Intrinsically safe maximum output current | 2.0A |

| Digital Signal Barrier |

|---|

| Explosion-proof parameters | Um=250V AC/DC, Uo=6V, Io=505mA, Po=0.75W IIC: Co=28μF, Lo=0.12mH |

| Operating voltage | 5V |

| Maximum withstand voltage | 6V |

| Terminal resistance | 12Ω |

| Polarity | Daul polarity |

| Weight | About 110g |

| Applicable equipment wiring | Two-wire, three-wire, four-wire |

| Explosion-proof certification | Zone 0, Zone 1, Zone 2; IIA, IIB, IIC, T4-T6 |

| Environment conditions | Continuous use temperature -20℃~60℃; Storage temperature -40℃~80℃ |

| Acoustic Imaging Guardian Minimum Leakage (Pressure 0.5 Mpa, 20-40kHz site environment noise 40dB) |

|---|

| Distance to Sound Source (m) | Leakage CCM (±1) |

| 0.5-2 | 28 |

| 2-4 | 46 |

| 4-6 | 47 |

| 6-8 | 50 |

| 8-10 | 53 |

| 10-12 | 66 |

| 12-14 | 70 |

| 14-16 | 78 |

| 16-18 | 90 |

| 18-20 | 97 |

-

20 years industry experience

-

24 hours Technical Support

-

Professional engineers on line response

-

2 hours response

Solution within 2 work days -

All life Costs Maintenance