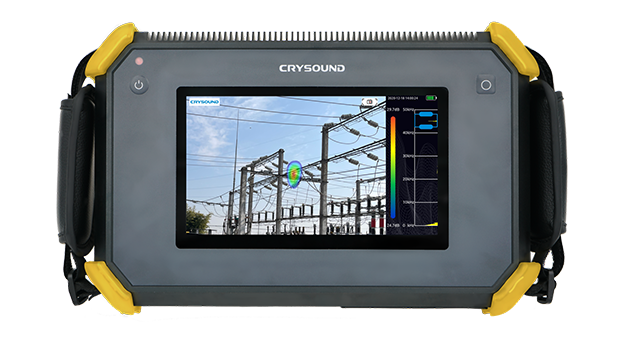

CRY8124 Acoustic Imaging Camera

The CRY8124 acoustic imaging camera excels at pinpointing leaks, identifying electrical partial discharge, and detecting mechanical deterioration. The CRY8124 sets a new standard for sensitivity and efficiency. Featuring 200 microphones (the most in the industry), the CRY8124 allows smaller leaks and partial discharges to be detected at a greater distance. The CRY8124 reporting software allows offline analysis, editing, and report generation, simplifying regular maintenance routines.

The Best Performance in the Industry

With 200 microphones, 100kHz bandwidth, and the fastest processor in the industry, the CRY8124 can pinpoint smaller leaks and partial discharges at a greater distance than any other system.

8 Inch, 2M Pixel Display for Clear Insights Into Problems

The CRY8124 display features 2K resolution, 6X digital zoom, and 600 nits display brightness for accurate viewing of field conditions in full sunlight.

8 Inch, 2M Pixel Display for Clear Insights Into Problems

The CRY8124 display features 2K resolution, 6X digital zoom, and 600 nits display brightness for accurate viewing of field conditions in full sunlight.

Multiple Communication Methods

Bluetooth and WiFi enable direct data transmission to local devices.

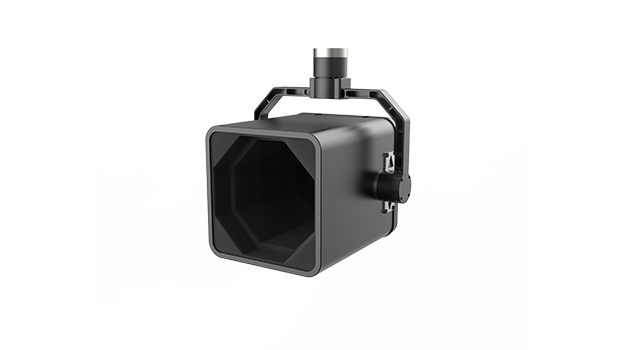

4 IEPE Sensor Inputs Enables a Wider Range of Applications

Up to 4 IEPE sensors (accelerometers, microphones, etc.) and thermal camera can be added to the system enabling complex detection scenarios and allowing for future expansion.

4 IEPE Sensor Inputs Enables a Wider Range of Applications

Up to 4 IEPE sensors (accelerometers, microphones, etc.) and thermal camera can be added to the system enabling complex detection scenarios and allowing for future expansion.

Up to 10 Hours of Operation

A single rechargeable Li-ion battery provides up to 5 hours of continuous operation. The CRY8124 comes standard with 2 batteries, offering a total runtime of up to 10 hours.

Ergonomic Design and Operation

With a weight of only 3 lbs (1.4kg), the CRY8124 features a rubber molded grip for safe, single handed operation.

Ergonomic Design and Operation

With a weight of only 3 lbs (1.4kg), the CRY8124 features a rubber molded grip for safe, single handed operation.

| Acoustic Specifications |

|---|

| Microphone array | 200 channels MEMS microphone |

| Frequency range | 2k - 100k Hz |

| SPL range | 28 - 132 dB |

| Test distance | 0.5 - 200 m (1 - 656 ft) |

| Minimum detectable leak | 10 m 2.7 bar 0.0029 L/min 0.5 m 1.9 bar 0.0028 L/min |

| Camera |

|---|

| Camera FOV | 66° |

| Camera pixels | 13M pixels |

| Focal length | 4.3 mm (0.17 inches) |

| LED light | 4*LED |

| Display |

|---|

| Resolution | 1920*1200 (6x digital zoom) |

| Touch screen | 8 inches, capacitive touch screen |

| Brightness | 600 nits, auto adjustment |

| Hardware port |

|---|

| USB-C 1 | USB 3.0 for charging, HDMI, data export |

| USB-C 2 | USB 2.0 for data export, USB sensor |

| 3.5 mm audio jack | Headphone output |

| TF card slot | External storage |

| SIM card slot | Inserting a 4G/5G network communication card |

| Analog input | Connect external analog sensor 4 channels, 20 - 100k Hz |

| General Specifications |

|---|

| Size | 270 * 190 * 51 mm 10.6 * 7.5 * 2.0 inches |

| Weight | 1.4 kg (3 lbs) |

| Wi-Fi | 802.11a/b/g/n/ac |

| Bluetooth | BT 5.2 |

| GNSS | GPS+BDS+GLONASS+GALILEO+QZSS |

| Operating temp. | -20 - +50 ℃, 10 - 95 % no cond. |

| Storage temp. | -20 - +70 ℃, 10 - 95 % no cond. |

| IP rated | IP54 |

| Storage size | 64G internal, 64G external |

| Battery |

|---|

| Battery type | Smart battery with indicator, replaceable |

| Battery capacity | 6600mAh @7.2V |

| Battery life | Up to 5 hours |

| Software |

|---|

| Function | Multi-point imaging, directional focus, distance measurement, leak volume estimation, PRPD spectrum, type recognition, picture labelling, report export, and etc. |

| Language |

|---|

| Language | Chinese, English, Korean, French, Japanese, Russian, German, Italian, EU Spanish, Portuguese, Hungarian, Dutch, Cambodian, Vietnamese, Turkish, Polish |

-

20 years industry experience

-

24 hours Technical Support

-

Professional engineers on line response

-

2 hours response

Solution within 2 work days -

All life Costs Maintenance