Measure Sound Better

Browse Authors

Blogs

We are excited to introduce the newest addition to our product portfolio – the CRY3000 Series Measurement Microphones, a groundbreaking lineup designed to set new standards in precision and versatility for acoustic measurement. Engineered for a wide range of applications, these measurement microphones deliver unparalleled performance and durability, making them the ideal choice for R&D, manufacturing, and QA/QC environments. To help our customers customize their equipment to meet specific needs, we provide both complete microphone sets and individual microphones and preamplifiers, making it easy to integrate with any existing setup. Versatile Microphone Options The CRY3000 Series features a wide range of microphones, including pressure-field, free-field, externally polarized, and pre-polarized options. This variety ensures that you’ll have the perfect tool for your specific measurement requirements, whether conducting detailed acoustic analysis or general sound recording. Versatile Microphone Options The CRY3000 Series features a wide range of microphones, including pressure-field, free-field, externally polarized, and pre-polarized options. This variety ensures that you’ll have the perfect tool for your specific measurement requirements, whether conducting detailed acoustic analysis or general sound recording. Superior Performance Specifications With low self-noise, an expansive frequency range, and broad sensitivity coverage, the CRY3000 Series Measurement Microphones meet the demands of diverse applications. We’ll help you choose the model that best fits your project’s needs to ensure optimal accuracy and reliability in every measurement. Advanced Materials for Enhanced Durability Each CRYSOUND microphone in the CRY3000 Series features a third-generation titanium diaphragm, a titanium protection grid, and a synthetic sapphire insulator. This combination ensures superior construction and stability, making them exceptionally resilient against the wear and tear of daily use and harsh environments. High/Low Temperature Resilience Designed to perform in extreme conditions, the CRY3000 measurement microphones function effectively in temperatures ranging from -30°C to +80°C (-4°F to +140°F). This adaptability ensures accurate measurements even in the most demanding environments. Compliance with International Standards The CRY3000 Series adheres to the IEC 61094-4:1995 Measurement Microphones - Part 4 standard, ensuring that our measurement microphones meet the highest international benchmarks for quality and performance. Seamless Connectivity With SMB, BNC, and Microdot interface options, connecting CRY3000 measurement microphones to your equipment has never been easier. These connection choices allow for seamless integration into your existing setup, reducing downtime and maximizing efficiency. Best-in-Class Solutions Within the CRY3000 Series, our best-in-class products deliver exceptional performance. Here’s what they offer: CRY3203: A high-sensitivity microphone with a frequency range of 3.15 Hz to 20 kHz, mirroring the audible frequency range of the human ear. It’s perfect for environmental noise measurements. CRY3403: A high frequency response microphone with an extended frequency range of up to 90 kHz and a sound pressure level capability of up to 165 dB. Its compact design makes it ideal for high-frequency and high-sound-pressure measurements. CRY3404: A 1/4-inch pre-polarized pressure-field high sound pressure level microphone that has been widely recognized and used in various high sound pressure testing environments. This microphone has a frequency range of 10 Hz to 20 kHz, making it an ideal choice for gunfire, blasting, aviation, and aerospace acoustic testing. CRY3261-S01: A specialized ultra-low-noise microphone set that includes the CRY3261 microphone, CRY516 preamplifier, and CRY575L power supply. This set can be used in a myriad of applications, from R&D to QA/QC and beyond. Each of these featured products delivers remarkable precision and durability, exemplifying our commitment to engineering excellence. The CRY3000 Series Measurement Microphones represent a major leap forward in acoustic measurement technology. With their impressive features and unmatched versatility, they are poised to become the go-to choice for professionals who demand the highest standards in accuracy, reliability, and performance. Experience the future of acoustic measurement with the CRY3000 Series Measurement Microphones. Discover the difference today! For more information, please contact us at info@crysound.com.

With noise pollution becoming a growing concern, it's more important than ever to create solutions that help technicians assess noise in various applications. At CRYSOUND, we understand the importance of precision and versatility in noise monitoring. That's why we offer a diverse range of feature-rich and comprehensive sound level meters, tailored to meet the unique needs of our customers. From standard models to multi-functional devices, our products ensure that every user can find the perfect fit for their application, budget, and requirements. Comprehensive Features for Comprehensive Monitoring The CRY2830 series of sound level meters stands out for its exhaustive feature set. It boasts integral measurement functionality, statistical analysis, 1/1 Octave Band Analysis, sound exposure measurement, continuous monitoring, 24-hour recording and storage capabilities, and much more. These features work in harmony to provide a comprehensive solution for noise monitoring, ensuring that no detail is overlooked. Whether conducting environmental noise assessments, evaluating machinery and construction noise impacts, performing quality control testing and certification of product noise levels, or taking occupational health measurements, the CRY2830 series has got you covered. Unparalleled Performances for Accurate Measurements The CRY2830 series sound level meters exhibit exceptional measuring performance, featuring a low noise floor for unparalleled sensitivity and a wide dynamic range, ensuring accurate measurements across diverse noise levels. Compliant with IEC 61672-1:2013 Class 2 standards, they utilize high-quality components to guarantee long-term stability and reliability, meeting stringent national and industry standards for precision. Versatile Connectivity for Seamless Integration One of the hallmarks of the CRY2830 series is its versatility in connectivity options. Equipped with Bluetooth®, WiFi, USB, and RS232 interfaces, these meters enable remote control and data transmission through various methods. This flexibility ensures seamless integration with existing systems and allows for quick and easy data sharing across teams. Whether working in the field or the office, you can rely on the CRY2830 series to keep you connected and informed. User-Centric Design for Enhanced Comfort At CRYSOUND, we believe that the best tools are those that enhance the user experience. That's why the CRY2830 series features an ergonomic design that ensures enhanced operational comfort and satisfaction. The meters come with an anti-drop wrist strap, providing an extra layer of protection against accidental drops. In addition, the CRY2832 has a 320*240 color display, offering high-definition clarity and brightness, ensuring a clear and vivid visual experience even in challenging lighting conditions. The CRYSOUND sound level meters represent a versatile and cost-effective solution that caters to the diverse needs of our customers. With comprehensive features, versatile connectivity options, a user-centric design, and industry-standard accuracy, these meters are must-haves for anyone involved in noise monitoring. Choose CRYSOUND for precise, reliable, and efficient noise measurement solutions. For more details, contact us through info@crysound.com

Leveraging Acoustic Imaging for Effective Partial Discharge Detection

Within the intricate tapestry of electrical systems, where the paramount significance of ensuring power distribution safety and reliability cannot be overstated, the swift detection and mitigation of partial discharge (PD) emerge as critical elements in averting equipment degradation and voltage instabilities. Acknowledging this pressing need, our discerning clients frequently seek insights into the practical applications of acoustic imaging technology to address PD challenges. In response to this demand, the CRYSOUND team takes pride in presenting a series of compelling case studies that highlight the precise utilization of acoustic imaging cameras across two pivotal domains: substations and power distribution systems. Application Scene: Electricity Substations 1. Switchgear The acoustic imaging camera efficiently detects partial discharge on switchgear cabinets via the inspection port. It aids personnel in confirming faults, minimizing downtime, and enhancing operational safety. 2. Wire The acoustic imaging camera excels in detecting subtle partial discharge in 110kV cables, ensuring early detection of potential issues. Its advanced technology facilitates swift identification of weak points, empowering proactive maintenance. 3. High Voltage Room Insulator Safety reigns supreme within high-voltage chambers. The handheld acoustic imaging camera provides a secure solution, enabling the precise detection of anomalies in insulators and equipment while maintaining safe distances. By leveraging this tool, risks to personnel are mitigated, and reliable power distribution is ensured. 4. Switch Insulator Surface discharge incidents often occur on the porcelain pillars of switch cabinets. Acoustic imaging camera empower inspection teams to swiftly and precisely evaluate component performance, promptly identifying hazards. Application Scene: Power Distribution System 1. Tower Insulator The acoustic imaging camera remotely identifies abnormal discharges from distribution line insulators, facilitating early detection. Its precision ensures proactive mitigation of potential issues, enhancing grid reliability and safety. 2. Cable Distribution Box Complex T-joints and busbar connections with high impedance are susceptible to discharge. Our acoustic imaging cameras simplify the identification of partial discharge, enabling precise localization and facilitating proactive maintenance to maximize grid stability and safety. 3. Drop Fuse Defective fuses threaten system stability. CRYSOUND acoustic imaging camera promptly pinpoints partial discharge, facilitating prompt response. 4. Support Insulator Continuous partial discharge in insulators erodes insulation properties. The height of support insulators hinders routine inspections. The CRYSOUND acoustic imaging camera enables safe, remote assessment, ensuring insulator integrity anduninterrupted power flow. Partial discharge silently jeopardizes the safety and reliability of electrical systems. Rapid and precise identification of fault areas through acoustic imaging cameras is imperative for accident prevention and upholding the integrity of power systems. Leveraging the capabilities of acoustic imaging cameras guarantees the security and reliability of our electrical infrastructure. For further information or to avail of our professional services, please do not hesitate to contact us. We are committed to providing effective solutions tailored to your needs!

Quick and Safe

In modern industrial production, gas leaks lead to resource wastage, and pose serious threats to employee safety and the environment. One of our clients in oil and gas industry reported that traditional leak detection methods can not accurately and efficiently locate leak points. Due to the hazardous environment, there are also potential safety issue for inspection personnel. At CRYSOUND, we understand the significance of this challenge and are here to provide valuable solution. As we know, gas leaks often occur due to factors such as aging from prolonged use, corrosion, and improper installation, typically at equipment connection points like flanges and valves. Gas leaks should not be underestimated. Periodically inspection and maintenance can ensure the safety of production, enhance corporate image and market competitiveness. For industrial production, quickly and accurately locating gas leaks is crucial. Providing assessments of leak volume and economic losses can serve as important references for corporate decision-making. Our client successfully identified multiple leakage points at flanges and valves in the factory by actively using a handheld acoustic imaging camera. The handheld acoustic imaging camera provided assessments of leak volume and economic losses, allowing the client to selectively repair the leak points with larger leak volumes based on the evaluation data, thereby reducing losses in the factory. For more information or to obtain professional services, please contact us. We are dedicated to provide effective solutions!

How to Conduct Effective Noise Monitoring and Control

Monitoring and controlling noise are closely linked, with monitoring providing the means and control serving as the goal. Relying solely on monitoring has limited impact on improving acoustic environments. As an example, one of our customers discovered that conventional monitoring equipment alone was inadequate for pinpointing the noise source. The tendency for nearby noise sources to evade detection hampered effective control measures. The customer needed a solution for tracing noise sources, requiring detailed information on noise exceedance events to identify and manage the source and type of noise effectively. To address this, we created a targeted solution by incorporating noise localization devices and pan-tilt cameras. This enhanced monitoring platform combines directional data with video footage, providing a comprehensive view of noise exceedance incidents. The noise localization devices accurately locate the noise in both horizontal and vertical dimensions. Through further processing, they associate the intensity and spatial distribution of the noise over time. This enables the relevant personnel to trace the noise at key historical time periods and its corresponding directional information, significantly improving work efficiency. In addition, the cameras and tracing devices are interconnected. When noise exceeds the limits, the cameras can perform corresponding actions to track the noise source based on the directional information provided by the localization devices, while preserving relevant video recordings. Ready to monitor and control noise? We are here to help! Our team of experts can provide solutions for your noise monitoring and control application. Contact us to learn more below.

CRY8120 Series

For technicians in industrial facilities, using acoustic imaging cameras can boost safety and reduce costs. How? By quickly identifying leaks and partial discharge without “reading bubbles”. Here at CRYSOUND, we are raising the bar with our latest innovation—the CRY8120 Series Acoustic Imaging Cameras. This cutting-edge device not only transforms industrial inspections but also sets a new standard for performance and efficiency. Let's check out the amazing capabilities, top-notch performance, and advanced features of the CRY8120, making it a must-have for industrial inspections. Unparalleled Capabilities: The CRY8120 acoustic imaging camera excels in various applications, including gas leak detection, electrical partial discharge identification, and mechanical deterioration monitoring. It outperforms traditional methods by providing results that are 10 times faster and more accurate. When it comes to gas leak detection, the CRY8120 swiftly pinpoints leak locations, estimates leakage volume, and potential economic losses in real-time. This capability reduces detection time, enabling faster repairs and reduced downtime. For electrical partial discharge detection, the camera displays PRPD charts in real-time, accurately identifying discharge types and aiding in informed decision-making for eff icient maintenance and prevention of potential failures. Best-in-Class Performance: Equipped with 200 microphones, a 100 kHz bandwidth, and 10 times more computing power, the CRY8120 acoustic imaging camera offers unparalleled performance. Its ability to pinpoint even the smallest and most distant leaks with exceptional accuracy is a testament to its superior specifications. Unlike other acoustic camera solutions on the market, the CRY8120 can detect leaks up to 200m away. Despite these advanced features, the CRY8120 remains lightweight at just 1.4 kg, making it highly portable and suitable for deployment in various challenging industrial environments. Enhanced Features for Convenience: The CRY8120 acoustic imaging camera goes beyond its primary functionalities by offering a range of convenient features that enhance the user experience. Bluetooth and Wi-Fi connectivity enable wireless data transmission and quick report export, eliminating the need for cumbersome cables and saving valuable time. Additionally, the integration of a thermal camera and contact sensors provides a comprehensive solution for diverse industrial scenarios, further extending the camera's versatility and applicability. Premium Display for Clear Visibility: Featuring an impressive 8-inch display with a resolution of 1920 × 1200 pixels, the CRY8120 delivers a clear and detailed view of field conditions. The high-resolution display accurately renders leaks and other issues, magnifying every detail with its 13 million pixels and 6x digital zoom. Moreover, the display's brightness of 600 nits ensures optimal visibility even in bright sunlight, making it suitable for outdoor inspections. Long-Lasting Battery Life: The CRY8120's battery life is designed to accommodate extended inspection sessions. With a single battery, it provides up to 5 hours of continuous operation. For longer durations, an additional battery ensures uninterrupted use throughout the day. This extended battery life eliminates the need for frequent recharging, maximizing uptime and productivity. Conclusion: The CRY8120 acoustic imaging camera from CRYSOUND represents a groundbreaking advancement in the field of industrial inspections. Its unmatched capabilities, enhanced features, and superior performance make it an indispensable tool for inspection teams across industries. With the CRY8120, inspections become faster, more accurate, and more efficient, ensuring the safety and reliability of industrial equipment. Embrace the next generation of acoustic imaging technology and elevate your industrial inspection capabilities with the CRY8120 Series. Fore more details, contact us by info@crysound.com

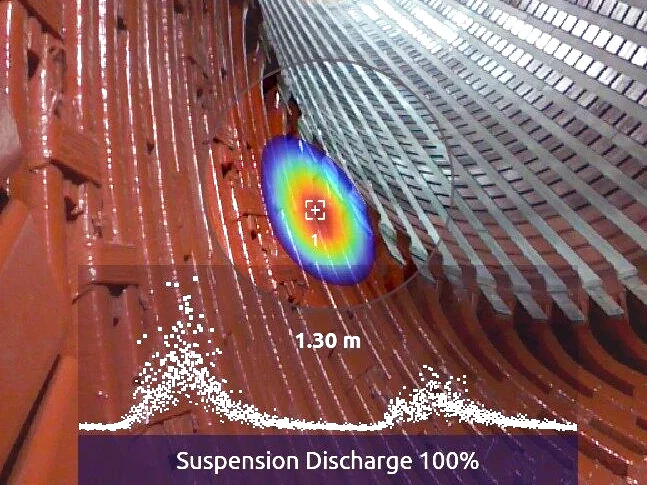

How to Address Partial Discharge in Generators

Partial discharge is a phenomenon that cannot be completely eliminated from high-voltage motors and generators. However, it is crucial to closely monitor and address partial discharge, as it can impact the performance of insulating materials. In the power industry, inspectors rely on observing the working status and performance of motors by studying the trend of partial discharge intensity in the generator. If the intensity of partial discharge in the generator shows an upward trend, it indicates a potential issue within the generator. At this point, it becomes necessary to analyze the underlying cause of this phenomenon and conduct a thorough examination of the motor's functionality. By taking proactive measures to address partial discharge, our clients can ensure the reliability and longevity of their generator systems. CRYSOUND's Acoustic Imager has proven to be an effective tool in detecting suspension discharge and surface discharge, assisting our clients in identifying and resolving potential problems early on. The CRYSOUND Acoustic Imager enables inspectors to analyze the intensity of partial discharge in the generator and closely monitor the functionality of the motors, thereby ensuring the safety of the environment. If you are facing similar challenges or have any questions related to partial discharge in generators, feel free to reach out to our team at CRYSOUND. We are here to provide expert guidance and support every step of the way. Contact us.