Measure Sound Better

Sound Level Meter Buying Guide

Table of content

In industrial production and environmental monitoring, excessive noise implies compliance risks or potential complaint disputes. To handle this, you need a professional sound level meter (SLM) that provides "credible, traceable, and analyzable data." Faced with price differences ranging from hundreds to tens of thousands of dollars, and a complex array of parameters, how do you choose without making costly mistakes? We have distilled the complex selection process into a "4-Step Decision Method" to help you quickly find the balance between your budget and your needs.

Step 1: Define the "Purpose" — Does the data need to be externally accountable?

This is the first watershed moment in selection, directly determining the equipment's "Accuracy Class."

Scenario A: Data must be "Externally Accountable"

Typical Use Cases: Environmental law enforcement, third-party testing, laboratory R&D, legal arbitration.

Must Choose: Class 1 Sound Level Meter.

Key Reason: The difference between Class 1 and Class 2 goes beyond reading errors. The core difference lies in the Frequency Response Range.

- Class 1 Devices (e.g., CRY2851): Typically cover a wide band of 10 Hz – 20 kHz, capturing extremely low-frequency vibrations and ultra-high-frequency noise, fully meeting strict standards like IEC 61672-1:2013 Class 1.

- Class 2 Devices: Usually have a narrower frequency range (e.g., 20 Hz – 8 kHz) with potential attenuation at high or low ends, making them unsuitable for strict metering or certification scenarios.

Scenario B: Used only for "Internal Management"

Typical Use Cases: Workshop inspections, equipment spot checks, community surveys, internal process comparisons.

Recommended: Class 2 Sound Level Meter.

Core Advantage: It meets the vast majority of industrial and environmental noise measurement needs and is the ideal choice for internal control.

Step 2: Clarify "Indicators" — What exactly are you measuring?

Selecting the wrong indicators renders the data useless. Focus on the following two points:

Frequency Weighting (A, C, Z): Which one to use?

A-Weighting (Most Common): Simulates the human ear's response (insensitive to low frequencies). Must be used for Environmental Noise Evaluation and Occupational Health Assessments (e.g., 85 dB(A) limits).

C-Weighting: Less attenuation at low frequencies, reflecting the total energy of the sound more truly. Often used for Mechanical Noise and Impact Sound where rich low-frequency components exist.

Z-Weighting (Zero Weighting): Flat response across the entire frequency range with no attenuation. Must be used when you need Spectrum Analysis or deep research into noise components to preserve the original signal.

"Instantaneous Value" or "Statistical Value"?

For quick site checks: Focus on Lp (Instantaneous Sound Pressure Level) and Lmax (Maximum Sound Level).

For scientific assessment or reporting: You must have Leq (Equivalent Continuous Sound Level). This is the core metric for evaluating noise energy over a period of time. Professional equipment (like CRY2850/2851) comes standard with integrating functions to automatically calculate Leq.

Step 3: Confirm if "Analysis" is needed — Do you need to find the noise source?

This distinguishes a "regular noise meter" from a "professional sound level meter." Looking at a total value (e.g., 85dB) only tells you "it's noisy here"; seeing the spectrum tells you "where is it noisy."

When do you need Spectrum Analysis (1/1 Octave, 1/3 Octave, or FFT)?

Noise Control: Determining if noise comes from a fan (aerodynamic noise) or a motor (electromagnetic noise).

R&D: Comparing sound quality differences between competing products or iterations.

Diagnostics: Distinguishing between high-frequency bearing squeal and low-frequency structural resonance.

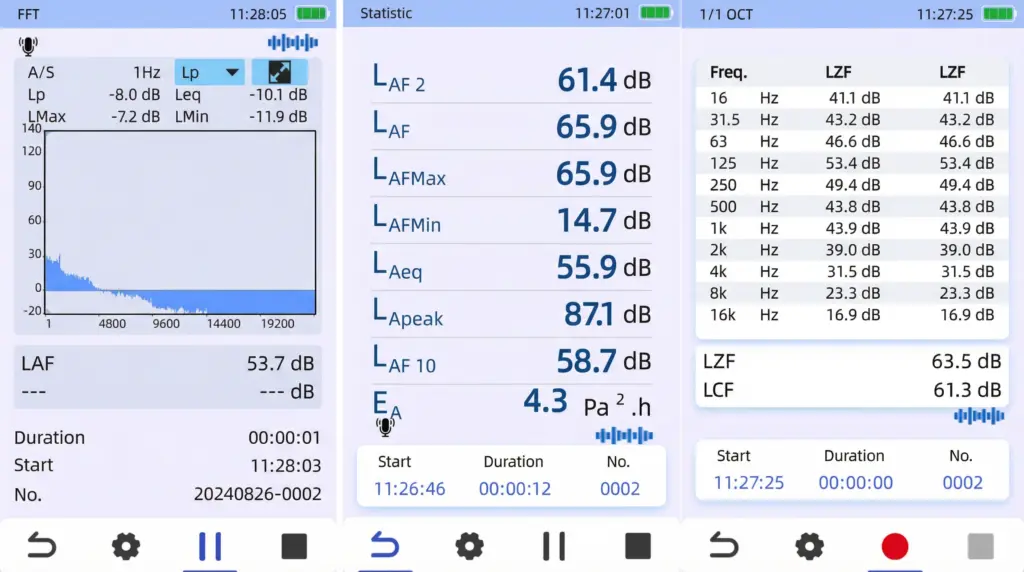

Selection Advice: Taking the CRY2851 as an example, it supports both OCT Analysis and FFT Analysis. If your goal is to "solve problems" rather than just "record numbers," be sure to choose a device with spectrum functions.

Step 4: Plan the Measurement "Mode" — Single measurement or long-term monitoring?

Many projects fail because the device "measures accurately, but is hard to use."

Dynamic Range: Say goodbye to "Manual Gear Shifting" Old equipment requires manual range switching, which is prone to errors. Modern sound level meters (like CRY2851) feature a >120 dB wide dynamic range, covering everything from whispers to roaring engines without switching gears—preventing errors and improving efficiency.

Data Export: Ensure data is "Portable and Usable" Ensure the device supports automatic storage to an SD card or internal memory and exports in universal formats (like CSV). Avoid the trap of "measuring data but failing to record it manually."

Remote Monitoring Capability (Essential for Outdoor/Long-term) For long-term scenarios like construction sites or traffic monitoring, the device must have:

Communication Functions: (LAN/Serial Port) for real-time remote data transmission.

Outdoor Protection: (e.g., paired with NA41 Outdoor Kit, IP65 rating) to withstand rain and dust; otherwise, the equipment is easily damaged.

Quick Selection Cheat Sheet To help you decide quickly, we have summarized three typical application scenarios based on the four-step method above:

The "Avoid Pitfalls" Checklist: Check these 5 points last

- Check the Standard: Confirm compliance with the latest IEC 61672-1:2013 standard.

- Check Bandwidth: Even for Class 2 meters, ensure the frequency range covers your main noise sources to avoid missed detections.

- Check Calibration: Buying a Class 1 SLM requires a Class 1 Sound Calibrator (e.g., CRY563A); otherwise, the system accuracy is downgraded.

- Check Range: Prefer "Wide Dynamic Range" or "Auto-Range" devices; refuse manual gear shifting.

- Check Accessories: Windscreens and protective cases are mandatory for outdoor use.

Selecting a sound level meter is essentially balancing "Risk vs. Cost." If you still have doubts about "Class 1 vs. Class 2" or "Whether Spectrum Analysis is needed," CRYSOUND is ready to provide full lifecycle support:

- Pre-sales: Our application engineers provide one-on-one scenario consulting to help you match precisely and avoid wasting money.

- After-sales: We offer a full suite of services from calibration and training to long-term technical support, ensuring a complete chain of evidence.

Instead of struggling with parameters alone, get in touch with our team using the form below to receive a configuration plan tailored to your application.

Related Products

CRY2833 Sound Level Meter

CRY2834 Sound Level Meter

CRY2851 Sound Level Meter

Get in touch

If you are interested or have questions about our products, book a demo and we will be glad to show how it works, which solutions it can take part of and discuss how it might fit your needs and organization.