December 29, 2025

Field Practice with UAIDS: Ultrasonic Acoustic Imaging Leak Detection

The Ultrasonic Acoustic Imaging Detection System (UAIDS) is developed by CRYSOUND and has already been deployed in multiple coal chemical, petrochemical and natural gas facilities. It is used for online leak monitoring in high‑risk areas. This article is written by the UAIDS project team at CRYSOUND based on real‑world deployment and operation experience. In a straightforward way, we will explain why such a system is needed, how it works in principle, what actually changes after it is put into service on site, and what it can and cannot do.

Why is traditional leak inspection so difficult?

In petrochemical plants, natural gas stations, coal chemical complexes and hazardous chemical storage yards, everyone understands how sensitive the word “leak” is. What really makes life hard is that many critical points are located high above ground, on pipe racks or at the tops of towers.

In the past, finding a small leak at height usually meant going through a process like this:

• Erect scaffolding or use a man‑lift and spend hours going up and down;

• Climb around the pipe racks with soap solution or portable instruments in hand;

• In winter, hands are frozen stiff; in summer, clothes are soaked with sweat, and even after checking a full round, people still worry: “There are so many valves and flanges, did we miss something?”

To sum up, traditional leak inspection at such sites has several persistent pain points:

• High locations: pipe racks at 20 meters or tower tops are hard to reach. Temporary access equipment is costly and high‑risk to use.

• Very quiet leaks: the ultrasonic signals generated by small leaks are drowned in the noise of pumps and fans, and are practically impossible to hear with the human ear.

• Invisible leaks: in the early stage, leak flow is tiny. Soap solution doesn’t bubble, and the smell is faint. By the time you actually see stains or smell gas, the leak has usually spread.

• Low efficiency: a single process area can easily have thousands of monitoring points. Manual “up and down” inspection is mostly spot‑checking, and it is very hard to achieve truly continuous and full coverage.

Traditional electrochemical, infrared and laser‑based detection methods are essentially point or line monitoring:

• Measuring at a fixed point to see whether the concentration exceeds a threshold;

• Watching along a single optical path to see whether any gas crosses it.

What operators actually want, however, is not only to know whether a leak exists, but also to see clearly, over a wide area, exactly where the leak is occurring.

That is precisely the problem that the ultrasonic acoustic imaging leak detection system (UAIDS) is designed to solve.

UAIDS: Turning “inaudible leak noise” into colorful soundmap on the screen

Basic principle: pressurized gas leak → ultrasonic signal → colorful soundmap on the image

When pressurized gas escapes through valve gaps, tiny flange cracks or weld defects, it interacts with the surrounding air and produces intense turbulence, creating a class of ultrasonic signals with distinct characteristics:

• The greater the leak rate, the stronger the ultrasonic signal;

• The higher the pressure difference, the more pronounced the acoustic characteristics;

• These signals are quite different from the lower‑frequency mechanical noise of motors and pumps, which makes it possible to pick them out from the background.

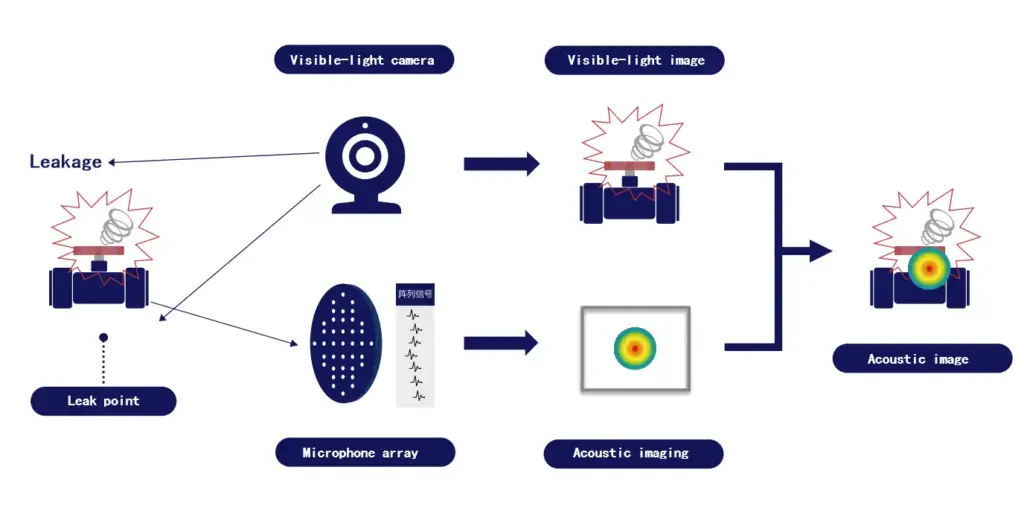

What UAIDS does is to convert this “inaudible sound” into “visible images” in a smart way:

• A multi‑channel ultrasonic sensor array is used to acquire ultrasonic signals simultaneously from multiple directions;

• At the front end, amplification, filtering and denoising are performed to remove electromagnetic interference and low‑frequency background noise as much as possible;

• Phase and amplitude differences between channels are analyzed to estimate the spatial distribution of sound energy and to infer from which direction and which area the leak noise is coming;

• The sound energy distribution is mapped into a two‑dimensional “heat map” and overlaid onto the live video image from the field.

In the end, the location with the strongest leak signal will appear as a red‑yellow‑green “cloud” on the display. For operators, the effect is very intuitive: wherever a cloud appears on the image, that is where something looks suspicious.

Engineering parameters: how far and how small can it detect?

Based on field tests and joint calibration results from multiple online projects, UAIDS exhibits the following typical capabilities in engineering applications:

Recommended detection distance: 0.5–50 m.

Within roughly 1–30 m, the system achieves better signal‑to‑noise ratio and imaging performance for small leaks.

Operating frequency range:

UAIDS operates in the ultrasonic band (above 20 kHz). A band‑pass filter is used to select the leakage characteristic band (typically 20–40 kHz), effectively suppressing audible‑range and low‑frequency mechanical noise.

Minimum detectable leak rate / orifice size (for typical conditions):

Under a minimum pressure difference of about 0.6 MPa, UAIDS can provide visual detection for early‑stage leaks around the 0.1 mm scale at valve gaps and flange micro‑cracks. The actual sensitivity varies with gas type, pressure, background noise and sensor placement.

Localization accuracy:

Within the recommended detection distance, UAIDS can provide leak localization with approximately centimeter‑level accuracy. Combined with the video image, it can effectively point to a specific piece of equipment or flange area on the screen.

These values are not rigid, unchanging limits, but rather typical engineering‑level performance verified across multiple real‑world projects.

Protection rating:

UAIDS has passed Ex ib IIC T4 Gb explosion‑proof certification and IP66 ingress protection tests, making it suitable for long‑term deployment in typical hazardous areas.

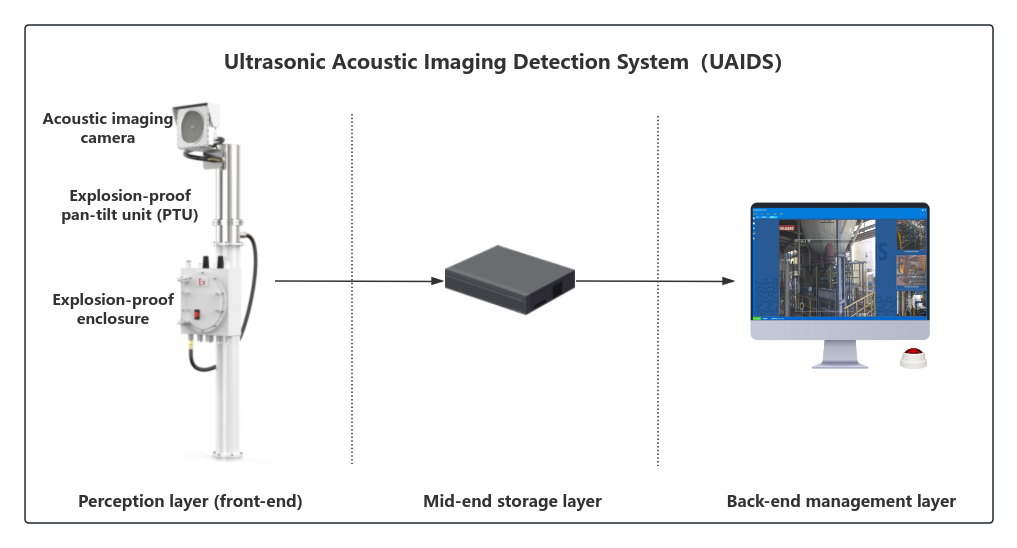

System architecture: more than a single sensor—it is a complete online system

UAIDS is not just a “smart sensor”. It is a complete online monitoring system that can roughly be broken down into three layers:

Front‑end sensing layer:

Pan‑tilt ultrasonic imaging leak detectors are deployed on site. They “listen” for leaks, capture the video image, and output the colored acoustic image. The pan‑tilt unit can rotate and tilt to scan a wide area.

Mid‑tier storage layer:

NVR and other storage equipment receive data from the front‑end devices, storing video, acoustic images and alarm records completely for later playback and incident analysis.

Back‑end management layer:

VMS and other management platforms connect to multiple front‑end devices, performing unified device management, detection control, alarm display and report generation, and presenting all data centrally on the control room video wall.

In short:

• The front end “sees” the leak point;

• The mid‑tier “remembers” the process;

• The back end “manages the whole site on one screen.”

A typical site: from climbing pipe racks to watching colored clouds

Let us take a typical coal chemical unit in Ningxia as an example. In this facility, 11 UAIDS units have been installed, covering gasifiers, heaters, tank farms and pipe racks. We can look at how day‑to‑day work has changed after UAIDS was introduced.

Before the retrofit: six people climbing for half a day and still feeling unsure

In a typical gasifier area, there are many high‑temperature and high‑pressure pipelines, valves and flanges inside the unit. Many key points are located around 20 meters above ground. The media are mostly flammable or toxic gases, so any leak not only wastes feedstock but also poses risks to personnel safety and plant stability.

Previously, inspection was carried out roughly as follows:

• Several inspectors and maintenance technicians would be assigned, scaffolding or access platforms would be prepared, and then they would go up onto the pipe racks;

• With soap solution and portable detectors in hand, they would walk along the racks and platforms, checking each flange and valve one by one;

• A single round could easily take half a day. During major inspections or special campaigns, they might have to repeat this work for days in a row.

Front‑line staff described this mode in three words: “tiring, slow, and worrying.”

Tiring: repeatedly climbing at height and twisting into awkward positions to look and listen close to equipment;

Slow: in an area with dozens or hundreds of points, checking each one by one takes a long time;

Worrying: with high background noise and many points, people always feel that eyes and ears alone may miss subtle issues.

During the retrofit: letting the pan‑tilt unit “sweep the area” every day

After assessing leak risks and inspection workload, we worked with the client to deploy several pan‑tilt ultrasonic imaging leak detectors at different platform elevations and connect them to UAIDS:

• High‑level pan‑tilt units cover key areas such as gasifier heads and pulverized coal lines;

• Mid‑level units cover lock hoppers, heat‑tracing lines, and dense clusters of flanges and valves;

• Low‑level units cover feed tanks and ground‑level pipelines.

Setting patrol routes and presets

For each pan‑tilt unit, several preset views are configured—for example, along a specific pipe rack, a group of flanges, or a particular platform area. Patrol cycles are set according to process sections and risk levels, with higher‑risk areas scanned more frequently.

Connecting to the central control system

All acoustic images and alarm information from the front‑end devices are fed into the UAIDS management platform. On the control room video wall, operators can see an overview of the unit, the colored cloud images, and the alarm list at the same time.

From then on, the devices basically follow the configured strategy and automatically “sweep the area” every day:

• Each pan‑tilt unit rotates and tilts along its preset route, scanning key areas at each elevation;

• Once characteristic ultrasonic leak signals appear at a certain location, a cloud will pop up at the corresponding position on the screen;

• When operators in the control room see an abnormal cloud, they can immediately notify maintenance, who go straight to the indicated valve or flange to verify and fix the problem.

After the retrofit: from “people hunting for problems” to “problems showing up on their own”

After a period of operation, feedback from the site has mainly focused on three aspects:

Fewer high‑level work operations

Where previously 2–3 comprehensive high‑level inspection rounds per month were needed, they have now been reduced to seasonal campaigns plus on‑demand checks when abnormal clouds appear. High‑level work is much more focused on specific issues, and overall frequency has clearly dropped.

Problems are found earlier and at a smaller scale

In the past, many small leaks were only noticed when people smelled something or saw visible signs. Now, as soon as a leak reaches the detectable threshold, anomalies can appear on the cloud image in advance, allowing corrective actions to be taken earlier.

Maintenance is more efficient

Previously, when someone reported “it smells like gas in that area,” maintenance teams had to check dozens of flanges and valves one by one. Now, UAIDS directly marks which piece of equipment shows a strong acoustic anomaly on the screen, so technicians can take their work orders and go straight to the target region.

Front‑line staff came up with a vivid summary:

“In the past, we went around looking for problems;

now, the problems show up on the screen by themselves.”

This, in essence, is the change from climbing pipe racks to watching colored clouds.

What can UAIDS do—and what can it not do?

From a safety and engineering perspective, understanding the system’s boundaries is very important—this is being responsible both to the plant and to the system itself.

What UAIDS is particularly good at

Wide‑area online monitoring of high‑level and high‑risk zones

By combining pan‑tilt units with sensor arrays, UAIDS can perform area coverage scans within approximately 0.5–50 m, making it especially suitable for 20 m pipe racks, tower tops and other locations where frequent manual access is difficult.

Visual localization

UAIDS not only tells you that “there is a leak”, but also shows a cloud directly on the image to indicate where it is. With centimeter‑level localization accuracy, it can quickly narrow down to a specific piece of equipment or flange area.

Around‑the‑clock monitoring

UAIDS can operate online 24/7, greatly reducing the dependence on “someone just happening to walk by that point” at the right time.

Compared with methods that rely on gas concentration build‑up, UAIDS is less affected by wind dispersing the gas, because it focuses on the ultrasonic signal generated by the jet itself, rather than on concentration readings at a single point.

Reducing high‑level work and repetitive inspections

By shifting from “frequent high‑level inspections” to “going up only when an abnormal cloud appears,” UAIDS helps reduce the workload and risk of working at height while improving overall inspection efficiency.

What UAIDS cannot do: limitations we need to acknowledge honestly

It cannot “see” leaks that are completely blocked

The ultrasonic leakage signal can only be effectively detected and imaged when it is able to propagate to the ultrasonic sensor array. If the leak source is completely blocked by structural components or thick‑walled shells along the path, the array will receive much weaker, or even no, leak signal.

Such areas need to be compensated by reasonable sensor placement, multi‑angle coverage or other complementary detection methods.

Strong ultrasonic interference sources require special design

Examples include process blow‑off points, steam vents that are open for long periods, and high‑frequency pneumatic devices, all of which can generate ultrasonic signatures similar to leaks. For these points, on‑site noise spectrum analysis is usually carried out during project design, and measures such as regional masking or logic filtering are introduced.

UAIDS is not a universal replacement, but a powerful complement

For some scenarios where gas concentration itself must be monitored—such as toxic gas alarms in occupied areas—electrochemical, infrared and laser‑based sensors are still necessary. UAIDS is better suited to building a “sonic radar network” that lights up leak risks on the screen as early as possible.

If we think of the entire leak‑monitoring setup as a team:

• Concentration sensors are responsible for “defending the bottom line” (whether concentration exceeds the limit);

• UAIDS is like an “early scout,” indicating where suspicious jets may be occurring and reminding you to take a closer look.

Conclusion: let the system see the problem first so people can solve it more safely

With an ultrasonic imaging leak detection system like UAIDS in place, the way work is done can change fundamentally:

• The system scans the unit along preset routes every day;

• Once a colored cloud appears on the display, personnel take their work orders and go up in a targeted way to deal with the issue;

• High‑level work becomes more focused and less frequent, and many leaks can be resolved before they cause noticeable impact.

For industries such as petrochemicals, natural gas and coal chemicals, UAIDS is not a flashy new gadget, but a way to identify leaks earlier, organize inspections more safely and manage risk more systematically.

It is important to emphasize that UAIDS is not a replacement for all traditional detection techniques, but an important piece of the puzzle. In actual projects, we usually combine UAIDS with concentration detection, process interlocks and manual inspections, using a layered defense approach to improve overall leak‑control capability.

If your site is facing issues such as many high‑level points with frequent scaffolding, late detection and slow troubleshooting of small leaks, or heavy inspection pressure at night and in bad weather, you may want to consider deploying an ultrasonic imaging leak detection system like UAIDS—letting problems first appear clearly on the screen so that people can address them more calmly and safely. To discuss your application or see whether UAIDS is a fit, please get in touch via our Get in Touch form.