December 25, 2025

AR Glasses Production-Line Testing Upgrade – Multi-Station Audio & VPU Solution

As the AR glasses market transitions from proof-of-concept to large-scale commercialization, product capabilities in audio and haptic interaction continue to expand, driving increased demands for production-line testing. With key modules such as audio and VPU (Vibration Processing Units), AR glass production-line testing is evolving from simple functional validation to consistency control aimed at enhancing real-world user experience. Based on actual mass production project experience, this article introduces audio and VPU testing solutions for different workstations, with a focus on free-field audio testing, VPU deployment, and fixture design, providing practical reference for scaling AR glasses manufacturing.

Accelerating Market Expansion of AR Glasses and New Trends in Production-Line Testing

As smart glasses products mature, their functional boundaries are expanding rapidly. According to various industry reports, the shipment volume and investment scale of AR glasses continue to increase, with the market shifting from concept validation to commercialization. Products driven by companies like Meta are increasingly capable of supporting voice interaction, calls, notifications, and recording, supplementing functions traditionally carried out by smartphones and earphones.

This shift has transformed AR glasses from a low-frequency conceptual product into a high-frequency wearable interaction terminal. Consequently, audio capabilities have become a core component of the smart glasses experience, directly impacting voice interaction and call quality. At the same time, vibration and haptic feedback have been introduced to enhance interaction confirmation and user perception.

As these capabilities become commonplace in mass-produced products, production-line testing is no longer just focused on whether basic functions work but is now required to handle multiple critical capabilities, such as audio and VPU, simultaneously. This shift presents new challenges for upgrading production-line testing solutions.

Audio Testing Solutions for Multi-Station Production Lines

Audio is one of the most directly influential functions on the user experience of AR glasses, and its production-line testing needs to balance accuracy, consistency, and production efficiency. In a multi-station production environment, audio testing is often distributed across several workstations depending on the assembly phase.

At the temple or frame workstations, audio testing focuses more on validating the basic performance of individual microphones or speakers, ensuring that key components meet the requirements early in the assembly process and avoiding costly rework later on in the process. At the final assembly workstation, the focus shifts to overall audio performance and system-level coordination. While different workstations focus on different aspects, the fixture positioning, acoustic environment control, and testing process design need to maintain consistent logic throughout.

CRYSOUND’s AR glass audio testing solutions are designed to address this need, with a unified testing architecture that allows flexible deployment across different workstations while maintaining stable and consistent results. The solutions can be divided into the following two types, meeting the aesthetic and UPH requirements of different production lines.

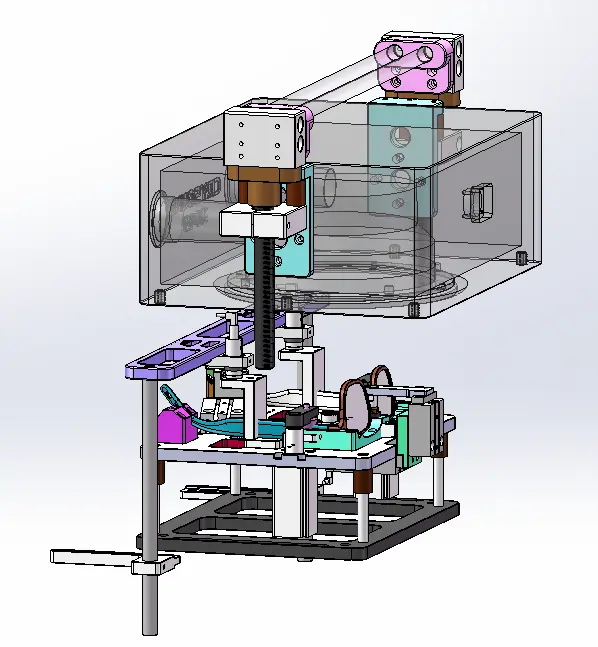

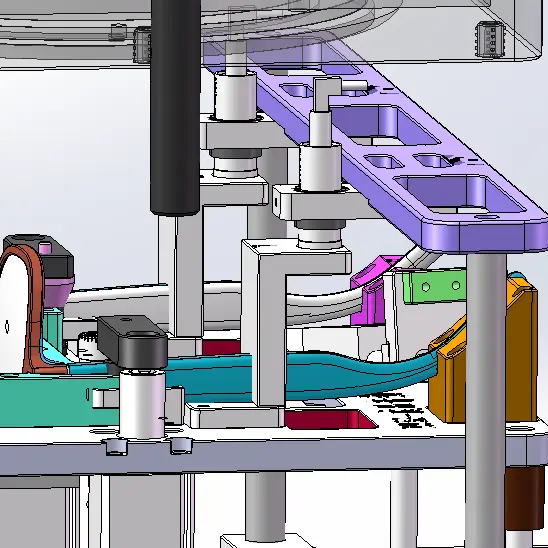

Drawer-Type Single-Unit (1-to-1)

- Easy automation integration

- Standing operation for convenient loading and unloading

- Simultaneous testing of SPK and MIC (airtightness), supporting multi-MIC scenarios

- Serial testing for left and right SPK, parallel testing for multiple MICs

- Supports Bluetooth, USB ADB, and Wi-Fi ADB communication

- Average cycle time (CT): 100s | UPH: 36

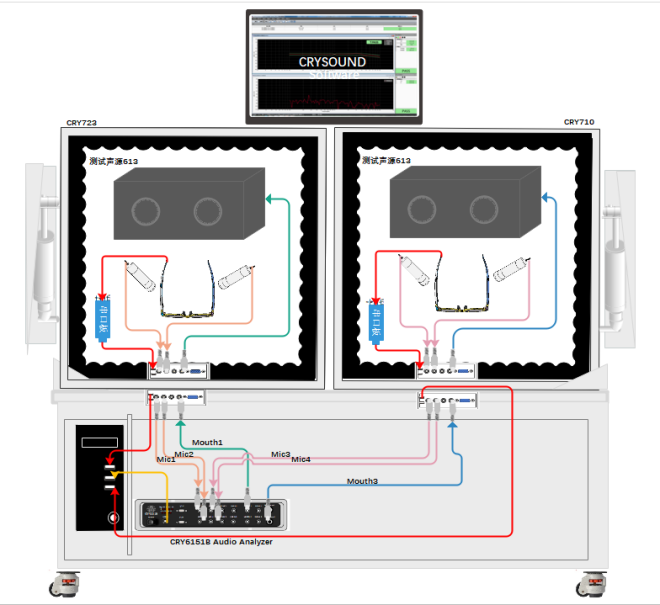

Clamshell Dual-Unit (1-to-2)

- Parallel dual-unit testing for improved efficiency

- Ergonomic seated operation design

- Simultaneous testing of SPK and MIC (airtightness), supporting multi-MIC scenarios

- Serial testing for left and right SPK (single box), parallel testing for multiple MICs

- Supports Bluetooth, USB ADB, and Wi-Fi ADB communication

- Average cycle time (CT): 150s | UPH: 70

Speaker EQ in AR Glasses: From Pressure Field to Free Field

In traditional earphone products, speaker EQ is usually built in a relatively stable pressure-field environment, where ear coupling and wearing style have a well-controlled impact on the acoustic environment. In contrast, AR glasses typically use open structures for the speakers, with no sealed cavity between the driver and the ear, making their acoustic performance closer to free-field characteristics.

This structural difference makes the frequency response of AR glasses speakers more sensitive to sound radiation direction, structural reflections, and wearing posture, and dictates that their EQ strategy cannot simply follow earphone product experience.

In the production-line testing and tuning process, the speaker EQ for AR glasses needs to be evaluated and validated under free-field conditions. Due to the open acoustic structure, the frequency response is more susceptible to structural reflections, assembly tolerances, and variations in wearing posture, making it difficult to rely solely on hardware consistency to ensure stable listening across different products.

By introducing EQ tuning, these systemic deviations can be compensated without changing the structural design, improving the consistency of audio performance during mass production. The focus of the testing solution is not to pursue idealized sound quality, but rather to capture real acoustic differences under stable and repeatable free-field testing conditions, providing reliable data for EQ parameter validation.

CRYSOUND supports customized EQ algorithms. In one mass production project, speaker EQ calibration was introduced at the final test station under free-field conditions, and the results were accepted by the customer, validating the applicability and practical significance of this solution for glasses products.

VPU Testing Solutions for AR/Smart Glasses

Why AR Glasses Include VPU (Vibration Processing Unit)

As AR/smart glasses increasingly support voice interaction, calls, and notifications, relying on audio feedback alone is no longer enough. In noisy environments, privacy-sensitive scenarios, or with low-volume prompts, users need a feedback method that does not disturb others but is sufficiently clear. This is where VPU is introduced.

Unlike traditional earphones, glasses are not always tightly coupled to the ear, making audio prompts more susceptible to environmental noise. By utilizing vibration or haptic feedback, the system can convey status confirmations, interaction responses, or notifications to users without increasing volume or relying on screens. Therefore, VPU becomes a key component for supplementing or even replacing some audio feedback in AR glasses.

Primary Roles of VPU in AR Glasses

In current mass-produced smart glasses designs, VPU typically serves the following functions:

- Interaction confirmation feedback: such as successful voice wake-up, completed command recognition, or the start/stop of recording or photo taking.

- Silent notifications: vibrational feedback in scenarios where audio prompts are unsuitable.

- Enhanced experience: boosting interaction certainty and immersion when combined with audio feedback.

These functions have made VPU an essential capability in the AR glasses interaction experience, rather than just an optional feature.

Typical VPU Placement in AR Glasses (Why in the Nose Bridge/Pads)

Structurally, VPU is typically located near the nose bridge or nose pads for three main reasons:

- Proximity to sensitive body areas: The nose bridge is sensitive to small vibrations, providing high feedback efficiency.

- Stable and consistent coupling: Compared to the temples, the nose bridge has a more stable and consistent contact with the face, ensuring better vibration transmission.

- Does not interfere with audio device layout: Avoids interference with speakers and microphones in the temple region.

Therefore, during production-line testing, VPU is often tested as an independent target, requiring dedicated verification at the frame or final assembly stage.

VPU Testing Implementation and Consistency Control on the Production Line

Based on the functional positioning and structural characteristics of VPU in AR glasses, VPU testing is typically scheduled based on the product form and assembly progress in mass production. In some cases, testing may even be moved earlier in the process to identify potential VPU issues before they are exacerbated in subsequent assembly stages.

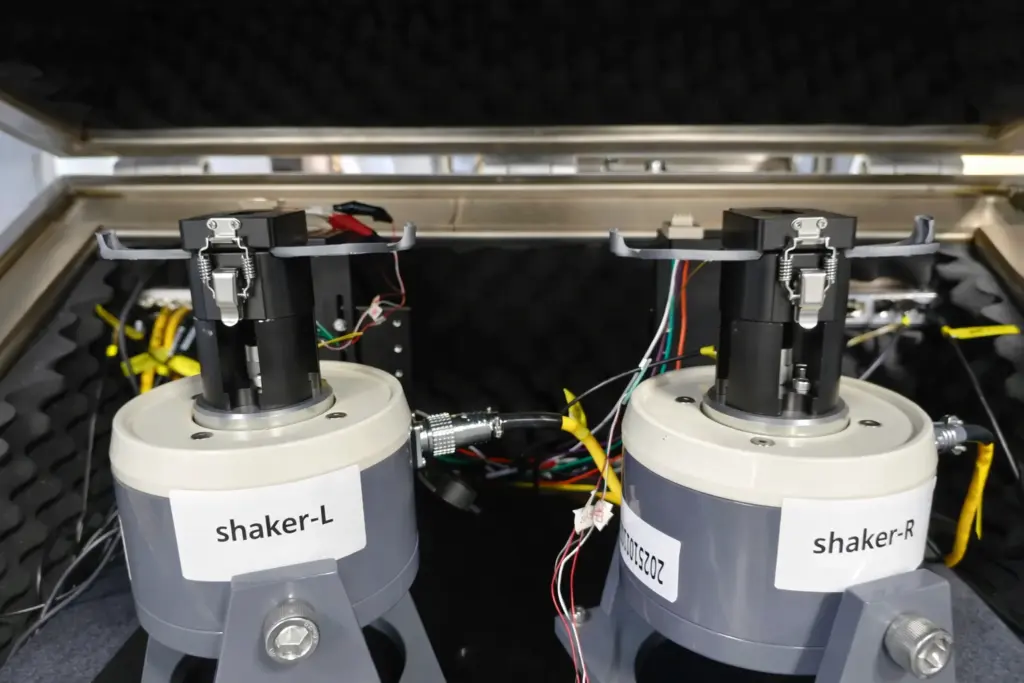

It is important to note that production-line testing environments differ fundamentally from laboratory validation environments. In laboratory testing, VPU is typically tested as a standalone component under simplified conditions and higher excitation levels (e.g., 1g). However, in production-line environments, the VPU is already integrated into the frame or complete product, requiring excitation conditions that closely mimic those of real-world wearing scenarios.

In practice, production-line VPU testing typically takes place in the 0.1g–0.2g, 100–2kHz excitation range, verifying consistency in VPU performance under realistic physical conditions.

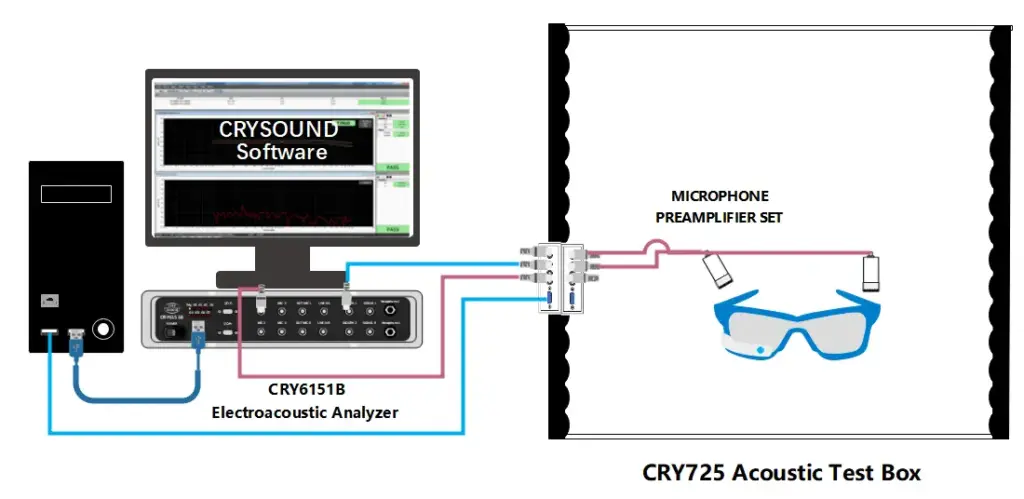

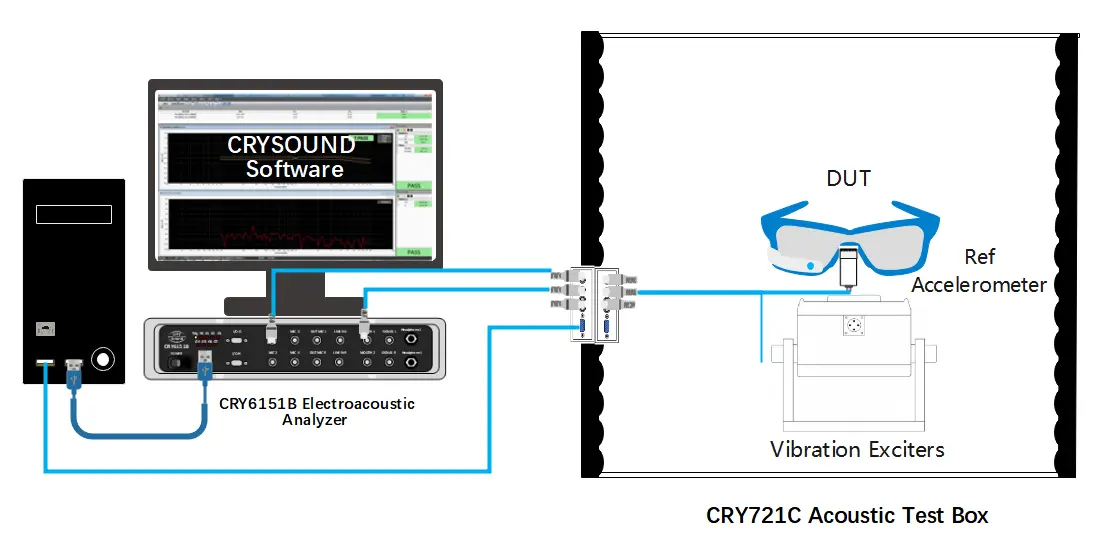

CRYSOUND’s AR glasses VPU production-line testing solution uses the CRY6151B Electro-Acoustic Analyzer as the testing and analysis platform. The vibration table provides stable excitation, and the product VPU synchronizes vibration response signals with a reference accelerometer. Software analysis evaluates key parameters such as frequency response (FR) and total harmonic distortion (THD).This test architecture balances testing effectiveness and production-line throughput, meeting the deployment needs for VPU testing at different stations.

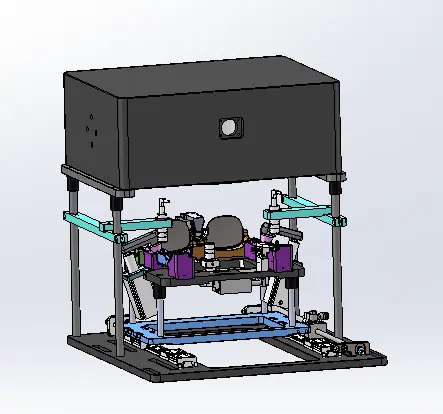

Compared to audio testing, VPU testing is more sensitive to testing configurations and fixture design, with less room for error and greater difficulty in consistency control. Based on experience from multiple projects, fixture design must fully account for structural differences in locations such as the nose bridge and nose pads. It is important to prioritize materials and contact methods that facilitate vibration transmission, and to design standardized fixture shapes that keep the fixture’s center of gravity aligned with the vibration table’s working plane, minimizing the introduction of additional variables at the structural level. By following these design principles, the stability and repeatability of VPU test results can be improved in a production-line environment, providing reliable support for validating the product’s VPU capabilities.

From Functional Testing to Experience Constraints

In AR glasses production lines, the role of testing is evolving. In the past, audio or vibration modules were more likely to be treated as independent functions, with the goal of confirming whether they were “functional.” However, with the current form of the product, these modules directly influence voice interaction, wearing comfort, and overall experience. As a result, the test results now serve as a prerequisite for the overall product performance.

For example, audio and VPU modules are no longer just performance verification items; they now play a role in the consistency control of the user experience. The interaction between audio performance, vibration feedback, and structural assembly means that production-line testing needs to identify potential issues that could affect the experience in advance, rather than just filtering out problems at the final inspection stage.

This change is pushing test strategies from “functional pass” to “experience control.”

If you’d like to learn more about AR glasses audio testing solutions—or discuss your blade process and inspection targets—please use the “Get in touch” form below. Our team can share recommended settings and an on-site workflow tailored to your production conditions.