December 19, 2025

Panelized PCBA Test for Multi-Product Lines

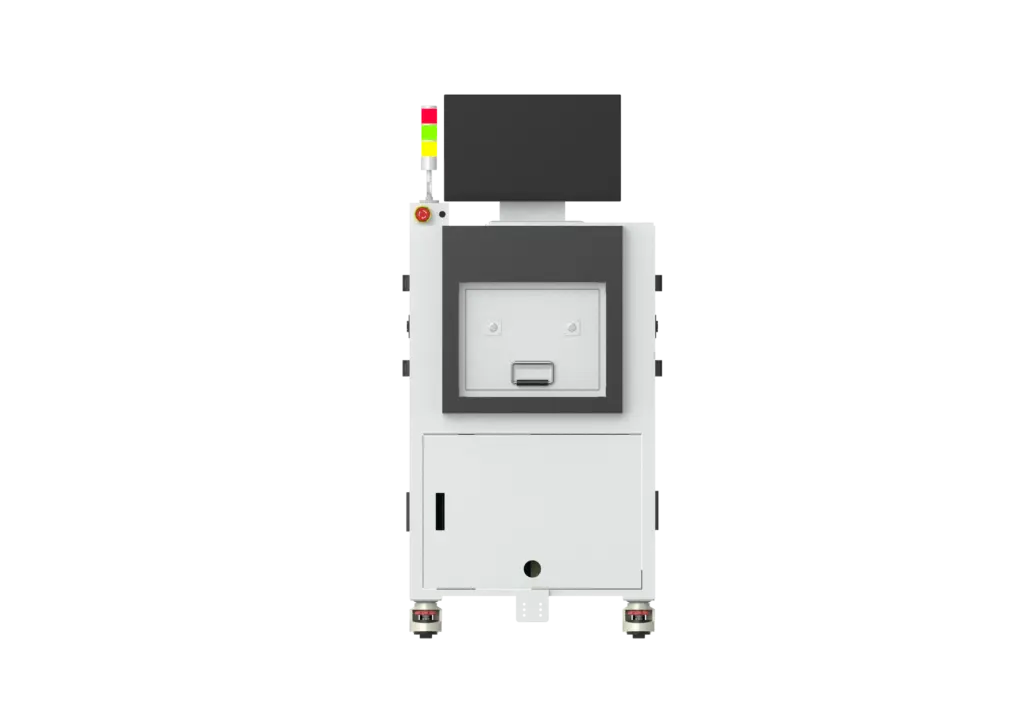

CRYSOUND’s PCBA testing solution integrates RF and audio performance validation within a 1-to-8 parallel architecture, enabling synchronized electrical, RF, audio, and power testing. This unified platform enhances PCBA test efficiency and adaptability for TWS, smart speakers, and wearables, driving cost-effective, high-volume production with streamlined integration.

Industry Pain Points: Challenges of Traditional PCBA Testing in Multi-Category Production

As smart hardware products diversify and iteration cycles shorten, traditional automated testing equipment increasingly exposes limitations—especially in cross-category production scenarios:

- Low space utilization: Traditional testers are typically customized for a single product category. Power testing for smart speakers, low-power testing for smart glasses, and RF testing for earbuds often require separate dedicated equipment, leading to excessive floor space usage and high expansion costs.

- High labor costs: Single-board testing systems require dedicated operators for calibration and supervision. Different operating logics across devices increase training costs, while peak production periods often rely on temporary staffing, causing labor costs to scale directly with output.

- Low production efficiency: Testing processes are largely serial. Panelized boards must be transferred between multiple stations, and special procedures—such as multi-channel audio testing for smart speakers—further extend cycle times, making it difficult to meet delivery demands.

These issues ultimately trap manufacturers in an operational dilemma of “higher output equals higher costs, and product changes equal line downtime,” limiting responsiveness and profit growth.

Core Advantages: An Integrated Solution for Multi-Scenario Applications

Leveraging a mature technical architecture and extensive industry experience, the CRYSOUND panelized PCBA testing solution abandons the traditional “single-function, single-application” design philosophy. Instead, it addresses real-world multi-category production needs to optimize both testing efficiency and cost control.

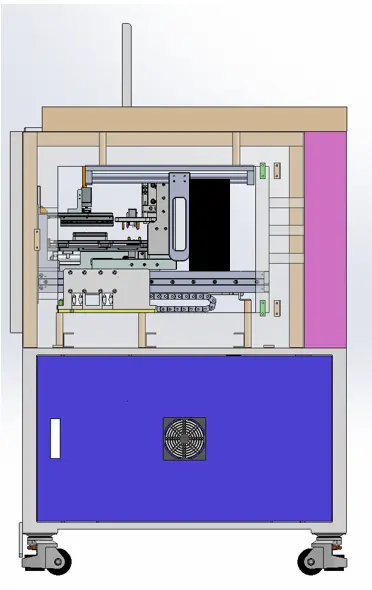

Fully Integrated Design with Over 50% Space Optimization

The solution integrates key testing functions—including electrical performance, RF validation, audio inspection, and power stability testing—into a single system, forming a one-stop testing workflow:

- Smart speaker applications: Integrated multi-channel audio testing and high-power stability modules eliminate the need for separate acoustic chambers and power validation benches. The system occupies only 25 m², saving 58% of space compared to traditional distributed layouts.

- Smart glasses applications: Designed for compact PCBA form factors, the system focuses on precise low-power current measurement and short-range RF validation, reducing damage risks caused by multi-station transfers.

- TWS/OWS earbud applications: RF, audio, and current parameter testing are completed within a single station. The 8-channel parallel testing architecture supports efficient panelized testing cycles.

Through functional integration, a single system can replace 3–4 traditional dedicated testers, significantly improving workshop space utilization and enabling flexible capacity expansion.

Intelligent Operations and Maintenance: Approximately 60% Labor Cost Reduction

With a standardized user interface, the solution supports semi-unattended testing operations:

- Automated process control: After manual loading, the system automatically completes barcode registration, synchronized multi-module testing, and real-time data uploads. Abnormal conditions trigger tiered alarm mechanisms without requiring full-time supervision.

- Unified operating logic: All systems use a standardized human–machine interface. Operators can manage multi-category testing after a single training session, significantly reducing training costs and operational errors.

- Improved maintenance efficiency: One technician can manage four systems simultaneously, compared with the traditional ratio of one operator for two machines—resulting in a 200% increase in labor efficiency.

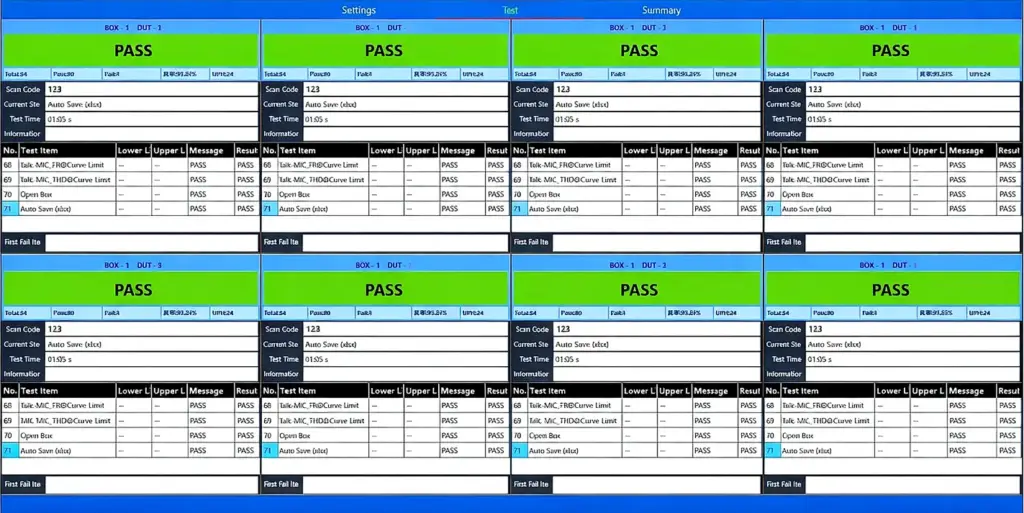

Parallel Testing Architecture: Doubling Production Throughput

By breaking through the bottleneck of serial testing, the multi-channel parallel testing design allows different test modules to operate simultaneously, dramatically reducing panelized board test cycles:

- Smart speakers: Parallel multi-channel audio and RF testing increases throughput from approximately 150 boards/hour to 300 boards/hour or more.

- TWS/OWS earbuds: The 8-channel parallel configuration achieves stable throughput of over 400 boards/hour, representing an efficiency improvement of approximately 150% compared with traditional single-channel systems.

This approach eliminates the need to “add more machines to increase capacity,” enabling manufacturers to meet peak-order demands while optimizing cost efficiency.

Standardized Technical Assurance: Precision and Reliability

All core test modules undergo strict calibration and validation, meeting recognized industry standards:

- Equipped with RF test modules, MBT electrical performance modules, and audio loopback closed-loop testing units, supporting precise testing of mainstream chipsets from Qualcomm, BES, JieLi, and others.

- Testing accuracy complies with IPC-A-610 PCBA acceptability standards. RF shielding effectiveness reaches ≥70 dB within 700 MHz–6 GHz, audio distortion remains <1.5% within 100 Hz–10 kHz, and electrical measurement accuracy is controlled within ±0.5% of full scale.

- Test data can be stored in multiple formats, enabling full traceability from pre-test to post-test stages and meeting ISO 9001 quality management system requirements.

Cost Advantages: Quantified Results Across Multiple Dimensions

The CRYSOUND solution delivers sustainable cost advantages across equipment procurement, operations, and quality control:

- Equipment investment: Integrated design reduces the number of dedicated testers required, lowering initial equipment investment by over 30% for multi-category production.

- Operational costs: Optimized space utilization and reduced staffing requirements lower rental and labor expenses, saving RMB 150,000–300,000 per system annually.

- Quality costs: Integrated testing minimizes handling damage during panel transfers. For lightweight boards such as those used in smart glasses, damage rates drop by 30%, while precise testing and data traceability keep defect rates below 2%, representing a 40%+ reduction compared with traditional approaches.

Case Studies: Efficiency Upgrades in Multi-Category Production

The following cases are based on anonymized production data from real customers and demonstrate actual deployment results:

Case 1: Mid-Sized TWS Earphone ODM (Monthly Output: 500,000 Units)

- Initial challenges: Four traditional test lines deployed in an 800 m² workshop, each requiring four operators. Single-line throughput was approximately 200 boards/hour, creating delivery pressure during peak seasons.

- Results after implementation: Four traditional lines were consolidated into two CRYSOUND test lines, freeing 200 m² of space for expansion. Each line required only 1.5 operators, saving RMB 45,000 per month in labor costs. Throughput per line increased to 400 boards/hour, doubling total monthly capacity to 1 million units, while delivery cycles shortened from 15 days to 10 days.

- Core value: Space utilization improved by 25%, labor costs reduced by 37.5%, and capacity increased by 24%.

Case 2: Smart Speaker Brand Factory (Monthly Output: 150,000 Units)

- Initial challenges: Multi-channel audio testing and RF testing were separated into two stations, occupying 60 m². High-power testing defect rates reached 1.2%, mainly due to board damage during transfers.

- Results after implementation: The integrated system occupied only 25 m², saving 35 m² of production space. Eliminating multi-station transfers reduced handling-related defect rates to 0.5%, preventing the loss of approximately 1,000 units per month.

- Core value: Space usage reduced by 50%, changeover efficiency improved by 25%, and transfer-related defect rates decreased by 31.8%.

The solution is now running stably across 10+ factories and 30+ production lines.

Key Differences vs. Traditional Automated Test Equipment

| Comparison Dimension | Traditional Automated Equipment | CRYSOUND Integrated Testing Solution |

Functional adaptability | Single-category customization; multiple systems required for cross-category production | Integrated multi-scenario testing covering earbuds, speakers, and glasses |

Changeover efficiency | No standardized process; line downtime up to 32 hours | Parameterized configuration; downtime reduced to 4 hours |

Space utilization | Dispersed single-function layouts with low efficiency | Integrated design saving 50%+ space |

| Initial investment | High due to multiple equipment purchases | Over 30% savings through integration |

CRYSOUND replaces the traditional “function-driven equipment” model with a “production-driven system” approach, enabling a shift from “adapting production to equipment” to “designing equipment around production.”

Choose CRYSOUND Panelized PCBA Testing for Certainty in Quality and Efficiency

As competition in smart wearable and consumer electronics markets intensifies, quality consistency and delivery speed are decisive factors. The CRYSOUND 1-to-8 PCBA comprehensive testing system is more than a piece of equipment—it is a complete solution for strengthening production-line competitiveness.

By ensuring reliable wireless performance, optimized power consumption, and built-in safety validation for every PCBA leaving the factory, CRYSOUND helps manufacturers maintain full confidence and control over product quality, even at large-scale production volumes.

If you’d like to learn more about PCBA testing—or discuss your blade process and inspection targets—please use the “Get in touch” form below. Our team can share recommended settings and an on-site workflow tailored to your production conditions.