December 16, 2025

IMU Test for Spatial Audio

Spatial audio performance can vary significantly across devices—even when similar audio algorithms are used. This article explains the role of the IMU in spatial audio, outlines key IMU testing challenges, and introduces CRYSOUND’s production-ready IMU testing solution based on a three-axis, three-degree-of-freedom (3-DoF) rotary table. You’ll learn the working principles, test flow, and application scenarios to help ensure stable and consistent spatial audio performance in mass production.

The Role of IMU in Spatial Audio: From Hearing Sound to Perceiving Space

In recent years, spatial audio has become a key feature in TWS earbuds, over-ear headphones, and AR/VR devices. Users now expect more than conventional stereo sound—they want to perceive sound direction and distance in a natural, three-dimensional space. When the head turns, the sound source should remain fixed in space; when the head tilts or nods, the sound field should respond accordingly.

To achieve this effect, a device must not only render spatial audio content, but also accurately understand how the user’s head is moving in real time.

This capability is enabled by the IMU (Inertial Measurement Unit). An IMU integrates gyroscopes and accelerometers to measure angular velocity, acceleration, and orientation. In spatial audio systems, it serves as the core sensor that tracks head motion and feeds motion data into spatial audio algorithms.

If the IMU lacks accuracy or stability, or if it does not align well with the audio algorithm, users may experience common issues such as:

- Response latency: the sound field lags behind head movement, causing discomfort or even mild dizziness;

- Tracking drift: sound positioning gradually shifts over time and no longer remains spatially fixed;

- Instability and jitter: noisy IMU output causes audible fluctuations in sound position.

As immersive audio, AR experiences, and spatial communication continue to evolve, audio devices are transforming from simple playback tools into intelligent perception systems. As a result, IMU stability and test quality have become foundational requirements for next-generation spatial audio products.

Three Major Challenges in IMU Testing for Spatial Audio

Despite the importance of IMU performance, testing and validating IMUs is often underestimated during development and mass production. In practice, the industry commonly faces three core challenges:

Lack of objective test methods tailored to spatial audio

Traditional audio testing focuses on metrics such as frequency response, distortion, and sensitivity. These methods are not suitable for evaluating dynamic spatial perception, and subjective listening tests or manual motion checks lack objective and repeatable standards.

Inability to reproduce real head movements with high precision

Spatial audio relies heavily on head movements such as turning, nodding, and tilting. Manual rotation cannot maintain consistent angles or speeds, nor can it reliably repeat motion patterns across devices. Without precise and repeatable motion simulation, IMU issues may go undetected before products reach users.

Low testing efficiency, making full inspection impractical

Manual testing is time-consuming and inconsistent. In mass production, it often forces manufacturers to rely on sampling inspection instead of full inspection, increasing the risk of quality variation.

At their core, these challenges stem from the absence of a controllable, repeatable, and quantifiable IMU orientation testing method.

Overview of CRYSOUND’s Spatial Audio IMU Testing Solution

To address these challenges, CRYSOUND has developed an IMU testing solution specifically designed for spatial audio and smart wearable applications. The goal is to provide an objective, automated, and production-ready testing approach.

The system consists of:

- PC-based test software for test control, data acquisition, and analysis;

- A three-degree-of-freedom rotary table for simulating head motion;

- Communication interfaces (such as a Bluetooth adapter) for data exchange;

- Shielded enclosure and customized fixtures to ensure stable connections and safe device mounting.

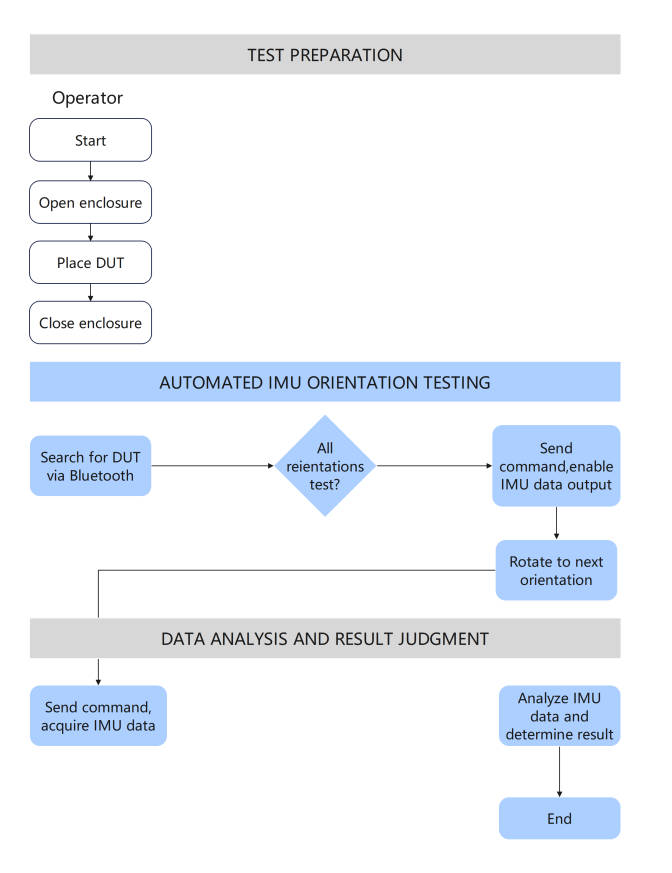

During a typical test, the host software establishes a connection with the device under test via Bluetooth or a wired interface, then sends commands to enable IMU data output. The rotary table sequentially moves to predefined orientations, while IMU data is collected and compared against reference angles. The entire process is automated, requiring the operator only to place the device and start the test, minimizing training effort and human error.

Key Hardware: Why a Three-DoF Rotary Table Is Ideal for IMU Testing

In spatial audio IMU testing, a three-degree-of-freedom rotary table provides a highly controllable and production-friendly solution. It accurately reproduces head movements across all three orientation axes and ensures consistent motion paths through programmatic control.

Compared with manual operation or simplified mechanical setups, a 3-DoF rotary table offers higher repeatability, better control over angle and speed, and more stable test cycles—making it well suited for mass production environments where consistency and throughput are critical.

The three axes correspond to common head motions:

- Yaw axis: simulates left-right head rotation;

- Pitch axis: simulates nodding movements;

- Roll axis: simulates head tilting.

The rotary table achieves an absolute positioning accuracy of ±0.05° and a repeatability of approximately ±0.06°, providing a reliable reference for evaluating IMU orientation accuracy.

System Features: How the Solution Addresses Real Production Needs

Building on this hardware and automated workflow, CRYSOUND’s IMU testing solution delivers value in several key areas:

- High-precision motion simulation

Servo-driven control and three-axis motion allow precise and repeatable reproduction of head movements, eliminating the uncertainty inherent in manual testing. - Controlled test speed and production throughput

With a maximum rotational speed of up to 200°/s and efficient Bluetooth communication, a six-orientation IMU test can be completed in approximately 60 seconds per unit, making full inspection feasible in production. - Objective and quantifiable evaluation

IMU output data is directly compared against known reference angles, reducing reliance on subjective judgment. Test results can be exported as reports or raw data and support MES integration for production tracking and quality analysis.

Typical Application Scenarios

This IMU testing solution is designed for manufacturers working with spatial audio and smart wearable products, including:

- Bluetooth earbuds and headphones, especially TWS and over-ear models with spatial audio features;

- VR controllers or devices requiring multi-orientation consistency checks;

- Smartphones and other consumer electronics requiring gyroscope validation;

- Smartwatches and fitness bands for IMU calibration and production testing.

If you’d like to learn more about IMU testing—or discuss your blade process and inspection targets—please use the “Get in touch” form below. Our team can share recommended settings and an on-site workflow tailored to your production conditions.