December 22, 2025

SonoDAQ Enclosure Coating Hardness Test

In real DAQ use, enclosure durability and scratch resistance directly affect service life and maintenance cost. This article shares a pencil hardness scratch test on the SonoDAQ top cover (PC + carbon fiber) and compares it with a typical laptop enclosure. The results show how the enclosure performs from 2H to 5H and why the surface finish helps it hold up in daily handling.

How Scratch Resistance Affects DAQ Use

When choosing a DAQ front end, engineers usually look first at the specs—sample rate, dynamic range, synchronization accuracy, channel count… But after a few years of real use, many realize that enclosure reliability and scratch resistance can be just as important to the system’s service life and day-to-day experience.

For soundand vibration test equipment, this is even more obvious. Typical SonoDAQ applications include NVH road tests, on-site industrial measurements, and long-term outdoor or semi-outdoor acquisition, where the device often has to:

- be carried frequently, loaded into vehicles, or fixed on fixtures or test benches;

- be moved between lab desks, instrument carts, and tool cases;

- remain in close contact with other metal equipment, screwdrivers, laptops, and more.

In such environments, a housing that scratches easily not only looks worn, but can also drive up maintenance and replacement costs. To better reflect daily handling, we ran a pencil-hardness scratch test on the SonoDAQ front-end upper cover and used a common laptop enclosure as a reference.

Test Setup

The test was performed strictly in accordance with ISO 15184:2020, and was intended to evaluate the scratch resistance of the UV-cured coating on the outer surface of the SonoDAQ front-end upper cover.

Samples

| Sample | Description |

| A — SonoDAQ top cover | Material: PC + carbon-fiber plate (top/bottom covers), with an internal aluminum frame and corner protection. |

| B — Typical laptop enclosure | Material: Plastic/metal housing with a sprayed coating. |

This test follows the pencil hardness test approach. Pencils of different hardness grades were used to scratch the enclosure surface under consistent contact conditions, and the surface was inspected for any scratches visible to the naked eye.

Test Tools

- Pencil hardness tester, additional weights can be added as required.

- Pencils: hardness grades 2H, 3H, 4H, and 5H.

Procedure

- Insert the pencil into the pencil hardness tester at a 45° angle, with a total load of 750 g (equivalent to applying 7.5 N to the coating surface).

- For each pencil hardness grade, scratch the enclosure surface three times and check whether any visible scratches appear.

- Keep the scratch length and applied force as consistent as possible to ensure comparability across hardness grades.

Results Criteria

- Whether visible scratches appear;

- Whether the surface gloss changes noticeably.

Results

From the results, we could see that the front-end enclosure showed different levels of scratch resistance under different pencil grades. To further validate durability, we ran the same pencil hardness test on a typical laptop enclosure. Laptop housings are usually plastic or metal and also have a painted surface. We used the same method as for the DAQ unit:

2H Pencil:

| SonoDAQ Pro | Typical Laptop |

|  |

Conclusion: Neither the SonoDAQ enclosure nor the laptop enclosure showed any obvious scratches; visually there was almost no change.

3H Pencil:

| SonoDAQ Pro | Typical Laptop |

|  |

Conclusion: Neither the SonoDAQ enclosure nor the laptop enclosure showed any obvious scratches; visually there was almost no change.

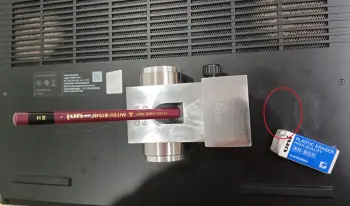

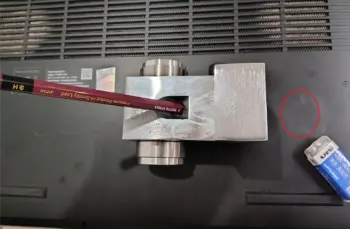

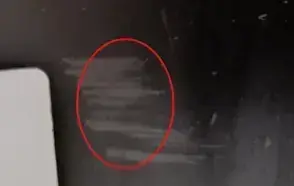

4H Pencil:

| SonoDAQ Pro | Typical Laptop |

|  |

Conclusion: At 4H, the SonoDAQ enclosure still showed no visible scratches; in contrast, the laptop enclosure exhibited clearly visible scuffs, essentially reaching the upper limit of its scratch resistance.

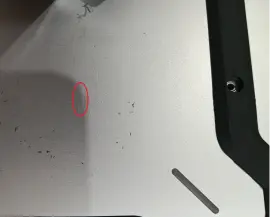

5H Pencil:

| SonoDAQ Pro | |

|  |

Conclusion: At 5H, light scratches began to appear on the SonoDAQ enclosure, indicating it was approaching its scratch-resistance limit.

Note that the pencil hardness test is primarily a relative comparison of scratch resistance between enclosures; it does not represent a material’s absolute hardness or long-term wear life. However, for assessing whether a surface is “easy to scratch” in everyday use, it is a very direct method.

If we translate the pencil grades into typical real-world scenarios:

- Accidental rubbing from most keys, equipment edges, and tools usually falls in the 2H-3H range;

- 4H-5H corresponds to harder, sharper, and more forceful scratching—often with some deliberate pressure.

At 4H, the SonoDAQ enclosure is still difficult to mark, and it only shows slight scratching at 5H. This means that during normal handling, loading, installation, and daily use, the enclosure is not easy to scratch.

Why It Holds Up

The SonoDAQ front-end enclosure uses a PC + carbon-fiber composite, which provides good mechanical strength and toughness. On top of that, the surface is finished with a spray-and-bake paint process plus a UV-cured top layer, which plays a key role in:

- Increasing surface hardness and improving scratch resistance;

- Improving corrosion resistance and environmental robustness;

- Balancing durability with a premium look and feel.

For instrumentation, “harder” is not always “better.” The right design balances scratch resistance, impact resistance, weight, and long-term reliability. As the results show, SonoDAQ’s enclosure is durable enough for real-world use.

For more information on SonoDAQ features, application scenarios, and typical configurations, please fill out the Get in touch form below to contact the CRYSOUND team. We will provide selection recommendations and support based on your test requirements.

Related Products

Get in touch

Read more

How It Delivers Nanosecond-Level DAQ Synchronization

OpenTest Website Launch : Reimagining Audio & NVH Testing