December 12, 2025

How It Delivers Nanosecond-Level DAQ Synchronization

In audio and NVH testing, keeping signals aligned in time is often harder than increasing channel count or resolution.

With a single chassis, synchronizing several dozen or even a hundred channels is no longer a big challenge. What really hurts is when multiple acquisition chassis are distributed across different locations and connected over a network, yet are still expected to maintain nanosecond-level—or at least sub-microsecond-level— synchronization. Otherwise, high-level analyses such as in-vehicle sound field reconstruction, array beamforming and localization, or structural modal testing will all suffer from misaligned time axes.

One of SonoDAQ’s core design goals is to make this kind of multi-device synchronization feel effortless: plug in the network cable and let the system take care of the rest, so that many units behave like a single instrument. The key enabler behind this is a carefully engineered timing architecture built around PTP and GPS.

Why Is Multi-Device Synchronization So Difficult?

In traditional architectures, multi-device sync is typically handled in a few ways:

- Relying on the operating system clock plus software alignment

- Using one device to output a clock or trigger and configuring all other devices as slaves

- Applying a simple network time protocol such as NTP

These techniques are barely acceptable when synchronization requirements are on the order of tens of milliseconds or a few milliseconds. But when you push into the microsecond or even nanosecond domain, several fundamental problems appear:

- Uncontrolled OS jitter: task scheduling, caching, and driver latency all make the apparent system time wander.

- Network latency and jitter: different paths and switches introduce variable delays that are hard to fully compensate in software alone.

- Long-term drift: even if devices are roughly aligned at startup, any small frequency error in the local oscillators will cause their time bases to slowly diverge over tens of minutes or hours.

SonoDAQ’s approach is to anchor every time-critical action to a common hardware time base, rather than relying on the operating system’s notion of time.

From Network Time to Hardware Time: PTP + PHC

The first step is to make sure every SonoDAQ unit shares the same absolute time.

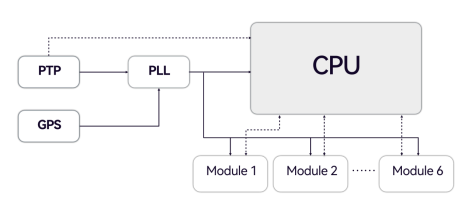

(1) PTP / GPS as the upstream clock

SonoDAQ can take a unified UTC reference either from IEEE 1588 PTP on the network or from an external GPS receiver. This reference is first fed into the on-board PTP Hardware Clock (PHC) as the local time base. In other words, PTP/GPS provides the world standard time, while the PHC is a local copy of that world time inside each acquisition chassis.

(2) Closed-loop correction every 1/128 s

A one-time alignment at startup is not enough. SonoDAQ continuously compares each local PHC against the reference clock at a period of 1/128 s:

- It evaluates both phase and frequency error at the current instant.

- It applies small, incremental corrections to the PHC, avoiding large jumps;

- Over long operating times, this closed loop continuously suppresses errors caused by crystal temperature drift and aging.

As a result, every SonoDAQ’s PHC closely tracks the PTP/GPS reference and does not quietly drift away over time. At this point, all devices have been brought onto the same nanosecond-grade hardware time base — this is the absolute timing foundation for all subsequent synchronization mechanisms.

PLL + 10 PPS: Bringing the Unified Time into Every FPGA

Once a common PHC is established, we still need to convert it into a tangible hardware signal that every FPGA can feel.

From PHC / 1 PPS to 10 PPS

PTP / GPS usually provides a 1 PPS (one pulse per second) signal. On SonoDAQ this 1 PPS is reshaped and multiplied by an on-board PLL to generate a stable 10 PPS pulse, which is then distributed to each FPGA.

Nanosecond Across Mulit Chassis: Benefits of a Unified Time Base

With this multi-layer timing architecture, SonoDAQ can provide nanosecond-scale alignment within a single chassis and sub-microsecond-level alignment across multiple chassis when deployed with an appropriate PTP/GPS reference and network topology.

For test engineers, these details ultimately translate into very tangible capabilities:

- Full-vehicle NVH testing: in-vehicle and exterior microphones and vibration sensors can be acquired in sync along with speed, torque, and shaft angle signals, enabling more reliable order analysis and transfer-path analysis.

- Multi-point structural modal testing: multiple chassis distributed across a large structure can capture excitation and responses with precise timing relationships, making high-order modal extraction and damping estimation more robust.

- End-to-end delay measurements: a unified time stamp allows you to measure the true latency from stimulus output to response input, which helps tune and compensate complex audio signal chains.

Engineering Experience: A Transparent High-Precision Timing System

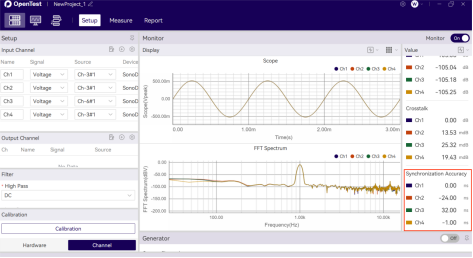

Although we have just walked through quite a bit of PTP, PHC, and 10 PPS plumbing, in practice engineers do not need to worry about any of this — SonoDAQ takes care of it automatically.

When you drag data from multiple SonoDAQ units onto the same plot in the software, what you see is already a single, seamlessly aligned time axis. That is exactly what we mean by nanosecond-level synchronization for practical data acquisition.

This is the original design intent behind SonoDAQ: to push the timing infrastructure to the limit, so that engineers can focus entirely on test strategies and data analysis.

To learn more about CRYSOUND SonoDAQ and OpenTest, please visit the CRYSOUND website or contact our team via the “Get in touch” form.

Get in touch

Read more

ISO 3744 Sound Power Testing with OpenTest

SonoDAQ for Sound & Vibration Testing