January 5, 2026

Bridging the A²B Audio Bus to Measurements

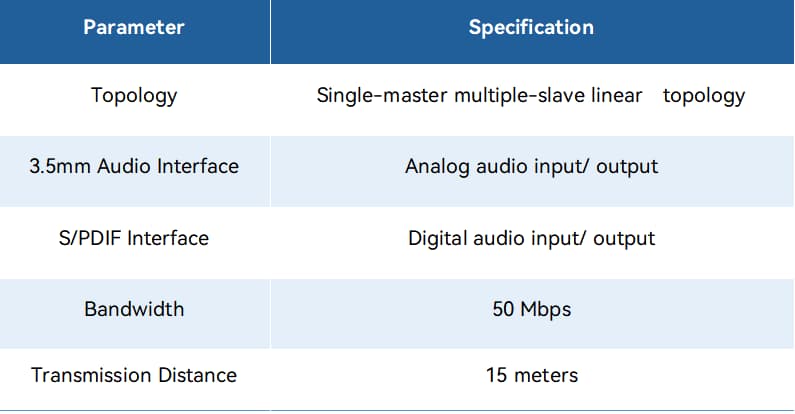

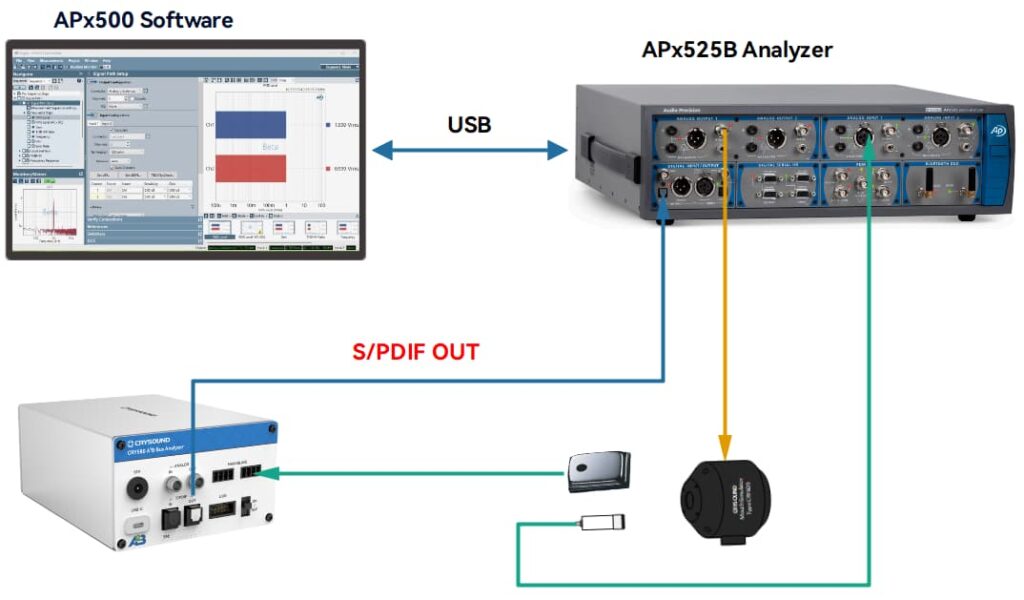

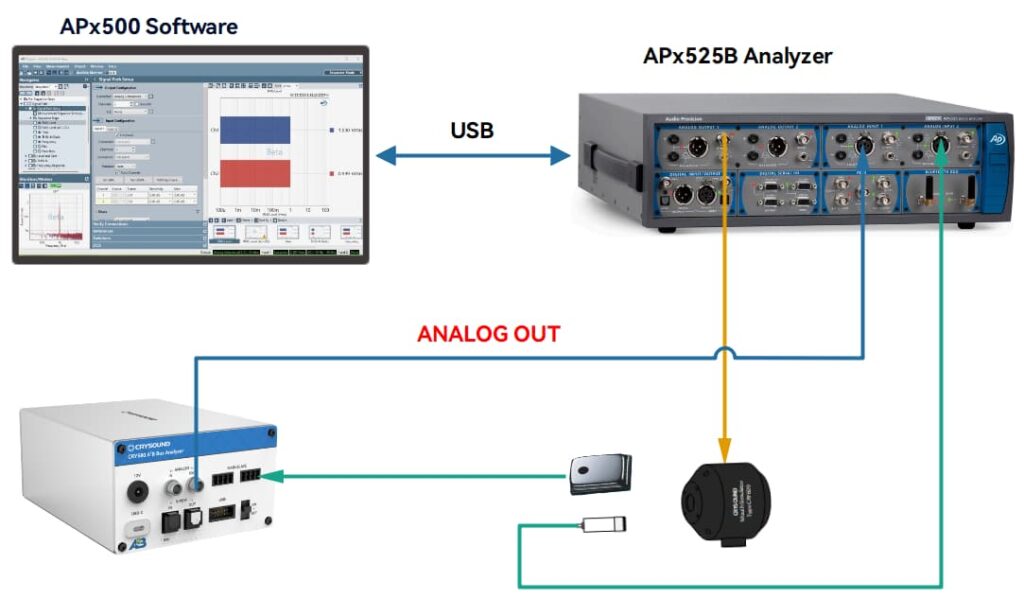

CRY580 A²B Interface is a bidirectional bridge designed to connect the A²B (Automotive Audio Bus) ecosystem with standard test & measurement setups (e.g., SonoDAQ, CRY6151B, Audio Precision). This article explains what makes A²B testing challenging—most analyzers don’t have a native A²B interface—and how CRY580 solves it by encoding/decoding A²B streams and converting them into measurable Analog or S/PDIF outputs, while supporting multi-channel I²S/TDM audio paths for fast, repeatable validation.

Faster Automotive Audio Testing with CRY580

One bidirectional A²B bridge for testing: apply an analog/digital test stimulus for A²B amplifier testing, and bring A²B microphone or accelerometer sensor streams out as analog or S/PDIF for measurement.

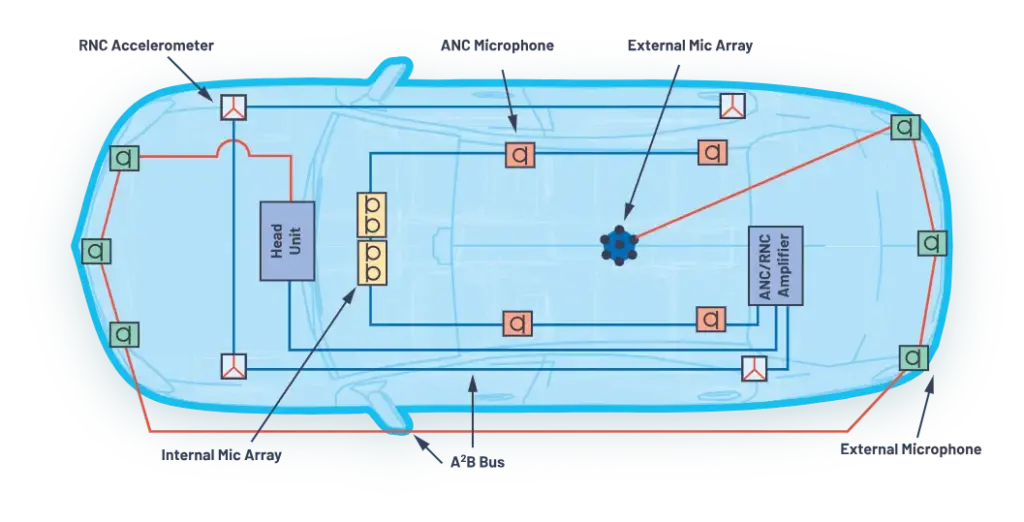

The A²B Audio Bus Is Reshaping In-Vehicle Audio

A²B technology enables cost-effective audio data transport over long distances, combining multichannel audio (I²S/TDM), control (I²C), and power delivery over affordable cabling.

- Bidirectional data transfer at 50 Mbps bandwidth

- Low and deterministic latency(50 µs)

- System-level diagnostics

- Slave nodes can be locally-powered or bus-powered

- Programmable using ADI’s SigmaStudio® GUI

- Uses cost-effective cables(unshielded twisted pair)

The Testing Pain: A²B Adds Performance—And Complexity

Traditional audio analyzers do not include A²B interfaces, making it impossible to directly test A²B devices. To perform accurate testing, a dedicated A²B codec is required to decode and convert A²B audio signals into standard analog or digital formats for measurement and analysis.

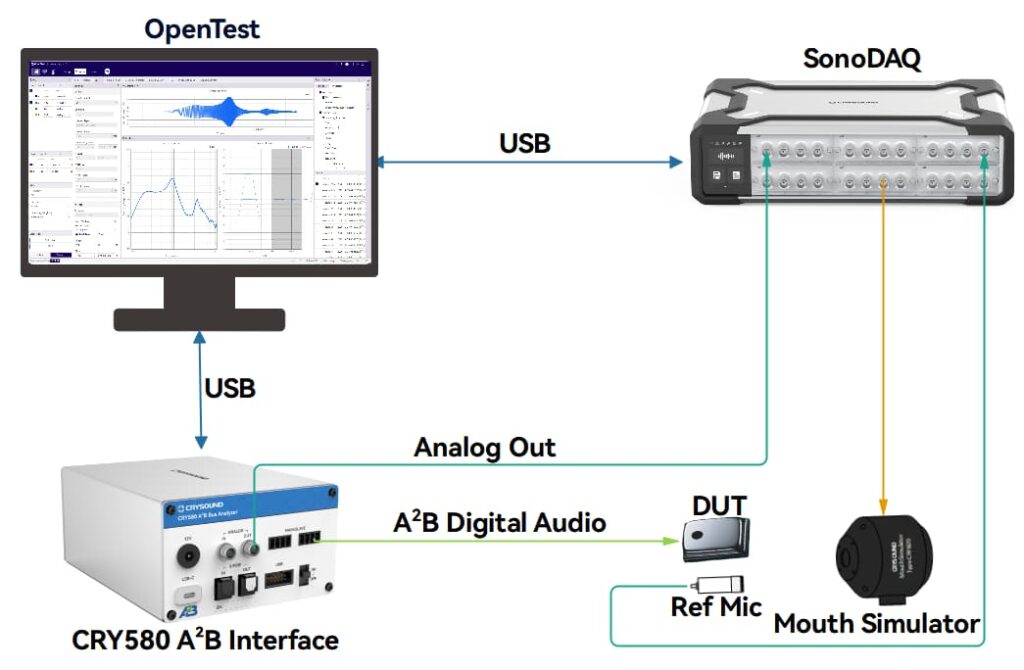

How Bridging to Measurements Works in Practice

How A²B Technology and Digital Microphones Enable Superior Performance in Emerging Automotive Applications

“Bridging” in practice means converting A²B audio signals into standard analog or digital formats for testing: for A²B amplifier testing, injecting analog/digital stimulus into the A²B bus; and for A²B sensor testing, extracting A²B audio data to analog or S/PDIF for measurement. The CRY580 serves as the ideal bidirectional test bridge, facilitating seamless conversion and measurement in both directions.

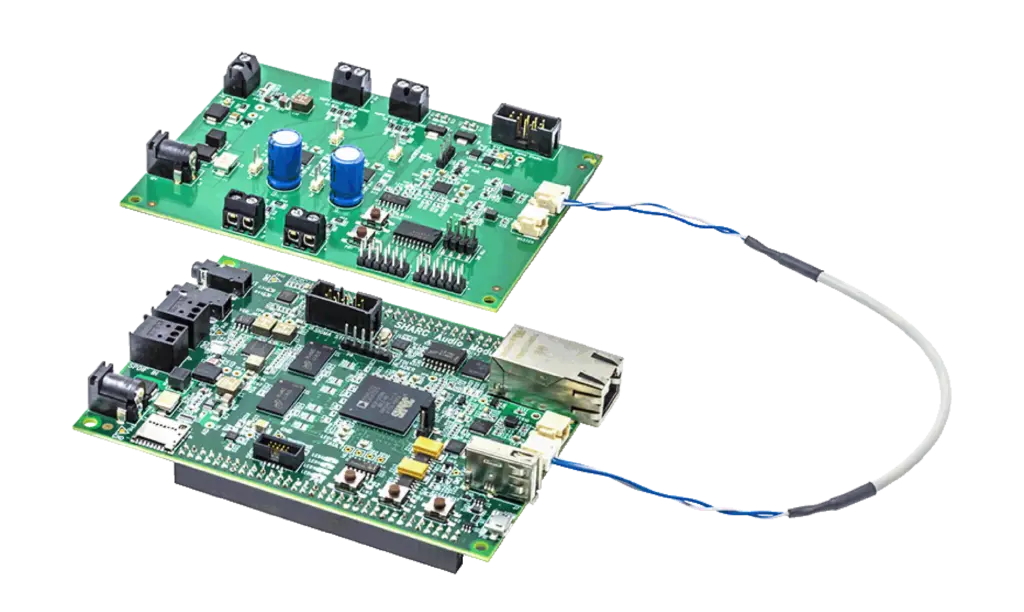

Introducing CRY580: An A²B Interface Built for Automotive Testing

The CRY580 is a versatile A²B interface designed to seamlessly bridge A²B networks with testing equipment. It provides both decoding and encoding capabilities, allowing for the efficient transfer of audio data between A²B devices and standard measurement systems. Whether you’re testing A²B microphones, amplifiers, or sensors, the CRY580 enables smooth and reliable testing workflows, ensuring accurate results across a range of automotive audio applications.

Who Buys CRY580 and What They Test

- OEM / Tier1 Audio Teams: Integration, debugging, and acceptance testing across A²B networks.

- A²B Microphone & Mic-Array Suppliers: Sensitivity, frequency response (FR), and phase consistency checks.

- A²B Amplifier / Audio Processor Suppliers: Amplifier testing with injected stimuli, as well as mapping and performance verification.

- Test Labs: Standardized A²B measurement processes and delivery.

- Manufacturing / EOL QC: Repeatable pass/fail testing with faster fault isolation.

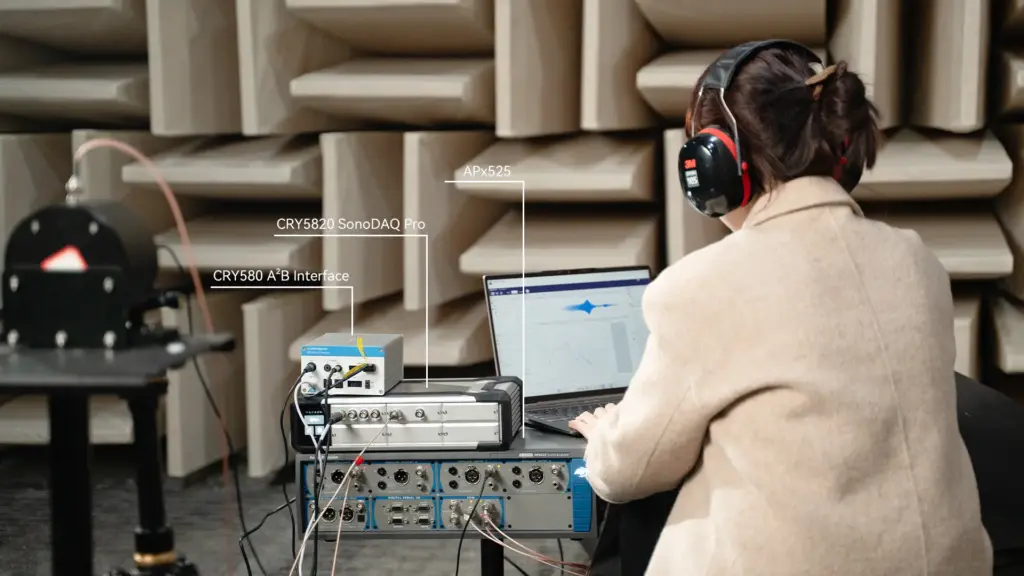

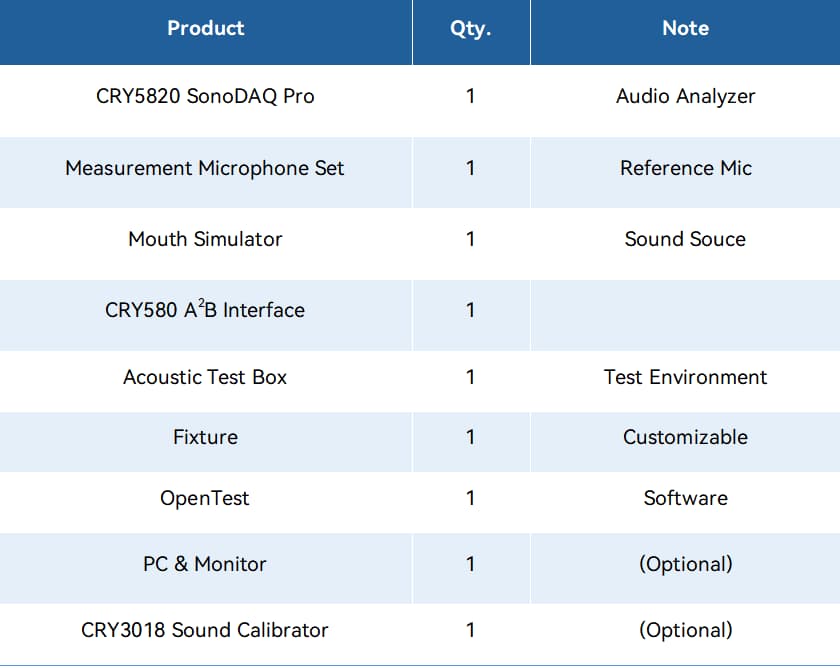

Typical Test Setups: More Than Just an Interface

At CRYSOUND, we provide more than just the CRY580 A²B interface. We offer a full automotive audio testing solution, including audio acquisition cards, microphones and sensors, acoustic sources, custom fixtures, acoustic test boxes, and vibration shakers, delivering a complete and streamlined testing experience.

The CRY580 A²B Interface can be used in conjunction with the Audio Precision.

Why CRYSOUND: A Complete Automotive Audio Test Ecosystem

The value of end-to-end delivery: reducing system integration time and minimizing coordination costs between multiple suppliers. We cover everything from R&D to production line testing.

CRY580 bridges A²B to mainstream test & measurement setups in both directions, turning complex in-vehicle audio validation into a faster, repeatable workflow from R&D to end-of-line production. To discuss your use case, system configuration, or a demo, please fill out the Get in touch form below and we’ll reach out shortly.