Measure Sound Better

What Does “1000 V Isolation” Actually Isolate?

Table of content

In many practical applications, data acquisition is not performed in an “ideal laboratory” environment. The device under test may be connected to mains power, distribution cabinets, frequency converters, or large electromechanical systems, while the acquisition card on the other side is connected via USB or Ethernet to a computer—sometimes operated directly by a person. These two sides are often not at the same electrical potential. If there is no effective electrical isolation inside the data acquisition card, this potential difference may propagate through signal lines, shields, or ground paths to the system side, leading to measurement distortion, interface malfunction, or even safety hazards. This is the fundamental reason why isolation exists in data acquisition systems.

What Is the Isolation Rating of a Data Acquisition Card?

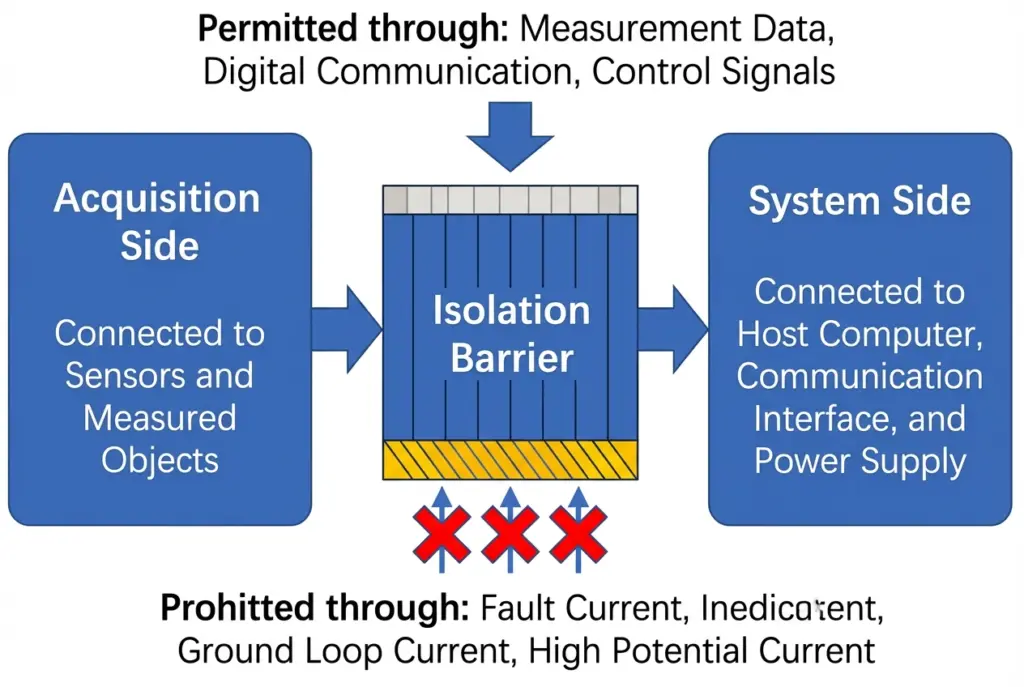

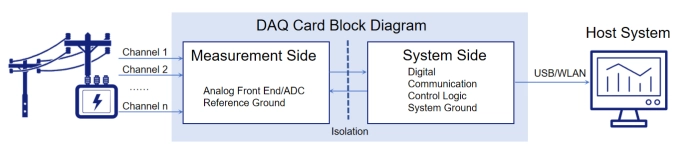

In a data acquisition system, the isolation rating is not a simple voltage number, nor is it equivalent to “the voltage that the input can directly withstand.” It describes whether there is a reliable electrical isolation barrier between the measurement side (connected to sensors and the device under test) and the system side (connected to the host computer, communication interfaces, and power supply), and under what level of voltage stress this isolation remains valid.

You can think of isolation as a bridge between two islands:

- The bridge allows information to pass—measurement data, digital communication, control signals.

- But it blocks dangerous currents—fault currents, ground-loop currents, and energy that could carry high potential to the host side.

For this reason, isolation in data acquisition systems typically addresses both safety and measurement stability at the same time.

Why Is Isolation Often More Important Than Accuracy Specifications?

In many field applications, engineers do not encounter problems such as “insufficient resolution,” but instead:

- The same system works well in the lab, but noise increases dramatically on site.

- Once multiple devices are connected together, the data begins to drift.

- Replacing the computer or using a different power outlet suddenly makes the problem disappear.

The common root cause behind these phenomena is often not algorithms or ADC performance, but rather improper handling of electrical potential relationships within the acquisition system. The value of isolation lies precisely here: by breaking unnecessary current loops and limiting the propagation paths of common-mode voltage and fault energy, isolation allows the acquisition system to behave in a controlled and predictable manner even in complex electrical environments.

In industry discussions, the core values of isolation usually fall into three categories: signal integrity, safety, and instrument protection.

Signal Integrity: Breaking Ground Loops and Improving Common-Mode Rejection

Many cases of “inaccurate measurement” are not caused by ADC resolution, but by unwanted currents flowing through ground wires or shields. When the device under test and the host computer, enclosure, or other equipment are at different ground potentials, connecting them via signal cables may form ground loops. Power-line interference and electromagnetic noise then appear as “baseline noise” or ripple in the waveform. Isolation improves this by breaking the current loop paths.

Safety: Confine High Potential and Fault Energy to the Measurement Side

When measurement points are located near mains power, distribution cabinets, or frequency converters, the real risk is not merely “high voltage,” but where abnormal voltage or fault energy may propagate. If there is no clear electrical isolation between the measurement side and the host side, this energy may travel through signal or ground connections into the computer or communication interfaces, causing equipment damage or safety hazards. Isolation establishes a clear internal safety boundary: high potential and uncertain electrical environments are confined to the measurement side, while the system side—where the host computer and operator reside—remains within a controlled and safe potential range. If an abnormal condition occurs, the problem is contained on the measurement side and does not propagate further.

Instrument Protection: A Larger Measurable Window Under High Common-Mode Voltage

A non-isolated acquisition system effectively binds the measurement reference ground to system ground or earth. As a result, the measurable input range is centered around earth potential. If the entire signal shifts to a high common-mode potential, the front-end amplifier or ADC may exceed its allowable range or even be damaged. An isolated system allows the measurement reference to “float,” enabling the input measurement window to be centered around the isolated local ground. This permits operation under much higher common-mode voltages, with the ultimate limits determined by the isolation barrier and input protection circuitry together.

Commonly Confused Isolation-Related Terms

Isolation is often misunderstood because a single term—“isolation voltage”—is used to answer very different questions. The following clarifies these related but distinct concepts.

Common-Mode Voltage

Common-mode voltage refers to the voltage that is simultaneously applied to both measurement inputs relative to the acquisition system reference ground. It is not the signal of interest. The measurement signal concerns the difference between two input terminals, whereas common-mode voltage describes how high the two terminals are elevated together relative to ground.

For example, in battery stacks or floating power systems, the signal itself may be only a few volts, but the entire source may be elevated tens or hundreds of volts above the acquisition card ground. In industrial environments, ground noise or electromagnetic interference may also impose time-varying AC voltage on both measurement leads. These “collectively elevated or oscillating voltages” constitute common-mode voltage.

Working Voltage

Working voltage is the voltage that can be continuously applied to a device over long periods. It is typically understood as the combination of measured voltage and common-mode voltage, and represents the condition under which the device can operate reliably over time.

Withstand Voltage

Withstand voltage refers to whether the isolation barrier can survive a very high voltage applied for a short duration without breakdown or damage. To verify this, a dielectric withstand (hipot) test is typically performed. During such a test, a voltage significantly higher than normal operating conditions is applied across the isolation barrier for approximately one minute. If no breakdown, abnormal leakage, or functional damage occurs, the isolation barrier is considered electrically robust.

It is critical to note that withstand voltage does not indicate that the device can operate continuously at that voltage. It is a safety and quality verification metric, demonstrating that the insulation will not fail immediately under abnormal or extreme conditions.

Input Overvoltage Protection

Input overvoltage protection specifies the maximum allowable differential voltage between the positive and negative terminals of the same input channel. Exceeding this limit may damage the input circuitry. This is fundamentally different from isolation withstand voltage:

- Isolation withstand voltage applies between the measurement side and the system side.

- Overvoltage protection applies between the positive and negative terminals of the same channel.

Measurement Category (CAT)

Measurement category defines the severity of transient overvoltage that a measurement system may encounter in its electrical environment. Categories increase from CAT I to CAT IV:

- CAT I: Low-energy electronic circuits.

- CAT II: Household appliances and receptacle outlets, typically protected by indoor distribution panels.

- CAT III: Industrial distribution cabinets and environments with large motors, pumps, or compressors, subject to switching transients and inductive load surges.

- CAT IV: Outdoor power distribution points exposed to surges and lightning strikes.

Pollution Degree

Pollution degree describes environmental factors such as dust, moisture, and condensation that affect insulation surfaces. Higher pollution degrees reduce effective insulation performance, requiring higher baseline insulation strength.

What Does “1000 V Isolation” Actually Mean?

When a specification states “1000 V isolation,” three immediate questions must be asked, otherwise the number has no real comparability:

- Is it AC or DC? Is it Vrms, Vpk, or Vdc?

- Is it withstand voltage (short-term) or working voltage (long-term)?

- What exactly is isolated? Channel-to-ground? Channel-to-channel? Measurement side to USB/host side?

The most important takeaway is this: “1000 V isolation withstand” does not automatically mean the system can continuously operate at 1000 V common-mode voltage, nor does it mean that 1000 V can be directly applied to the input. Continuous capability depends on working voltage, measurement category, input overvoltage protection, and the entire system chain including sensors, cables, and terminals.

How Isolation Is Implemented: Isolation Barriers and Signal Transfer Methods

Isolation is not simply “air separation,” but a combination of structure, materials, and signal-coupling mechanisms.

Common isolation signal-transfer methods include:

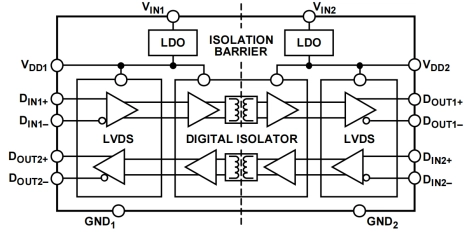

Inductive / Transformer-Based Isolation

Inductive isolation transmits energy or information via magnetic fields rather than direct electrical conduction, fundamentally based on Faraday's law of electromagnetic induction.

Inside the chip, planar coils are fabricated on silicon or within the package, forming transformer-like structures.

- Transmitter side: current → coil → alternating magnetic field

- Receiver side: magnetic field variation → induced voltage → signal recovery

Advantages include very high common-mode transient immunity (CMTI), high speed, low jitter, long-term stability, and excellent channel consistency. Disadvantages include higher power consumption and cost compared with capacitive isolation.

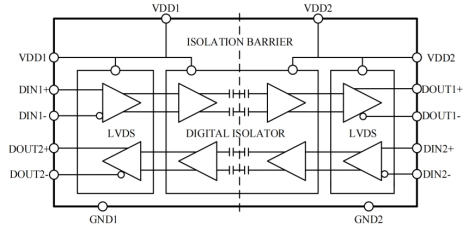

Capacitive Coupling

Capacitive isolation uses the “DC-blocking, AC-passing” property of capacitors to achieve voltage isolation, relying on electric-field variation within the dielectric.

Signal variation → electric-field variation → displacement current coupling

Advantages include low power consumption, small die area, high integration, lower cost, and high speed. Disadvantages include higher sensitivity to common-mode dv/dt, stricter PCB symmetry requirements, and higher dependence on reference-ground layout.

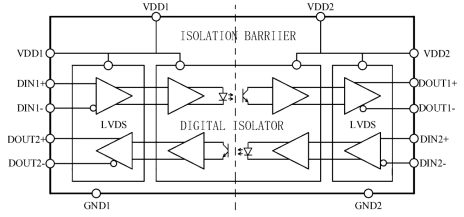

Optical Isolation

Optical isolation uses light as the isolation medium, with air or transparent insulation providing physical separation. The principle is photoelectric conversion plus spatial isolation.

Electrical signal → LED emission → photosensitive device → electrical signal

Advantages include simple structure, extremely high withstand voltage, good performance for low-frequency and switching signals, and strong EMC characteristics. Disadvantages include slower speed due to device latency, higher variability, and unsuitability for high-precision synchronous systems.

Comparison of Isolation Technologies

| Item | Inductive | Capacitive | Optical |

|---|---|---|---|

| Withstand voltage | ★★★★☆ | ★★★☆ | ★★★★★ |

| Transmission speed | ★★★★☆ | ★★★★★ | ★★ |

| Common-mode immunity | ★★★★★ | ★★★☆ | ★★ |

| EMI immunity | ★★★☆ | ★★★★ | ★★★★★ |

| Stability | ★★★★★ | ★★★★ | ★★ |

| Low power | ★★★ | ★★★★★ | ★★ |

| Suitable for DAQ | Recommended | Recommended | Not recommended |

A frequently overlooked but critical metric here is CMTI. In high dv/dt environments such as inverters, SiC/GaN power supplies, and motor drives, the issue is often not how high the static common-mode voltage is, but how fast it changes. Rapid high-voltage transients may couple through parasitic capacitances across the isolation barrier, disrupting or corrupting data transmission. Therefore, isolation must withstand not only voltage magnitude, but also voltage transition speed.

Common Isolation Topologies in Data Acquisition

Before asking whether a DAQ card is isolated, a more important question should be asked: where is the isolation applied?

Different products may use entirely different isolation domains, resulting in very different capability boundaries and application suitability.

Common DAQ isolation topologies include:

- Channel-to-system-ground isolation

- Bank (group) isolation

- Channel-to-channel isolation

Channel-to-System-Ground Isolation

Definition: Each channel (or group of analog front ends) is isolated from system ground and host ground, while channels typically share a common reference ground.

This topology can:

- Break ground loops between the measurement side and the host side.

- Prevent high potential or fault energy from reaching the computer, USB, or network interface.

- Significantly improve stability when measurement and host grounds differ.

The entire DAQ effectively “floats” with the device under test, while the host remains on the safe side.

Suitable scenarios include industrial field measurements where all channels share the same potential.

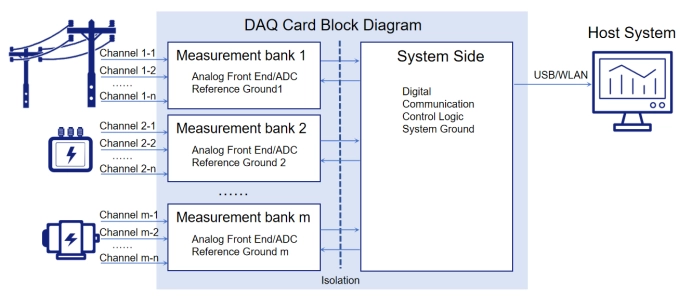

Bank Isolation

Definition: Channels are divided into groups (banks). Each bank has its own isolation domain, with isolation between banks and between each bank and system ground.

This topology allows multiple independent systems to be measured simultaneously while preserving multi-channel synchronization within each bank, balancing cost, size, and isolation capability.

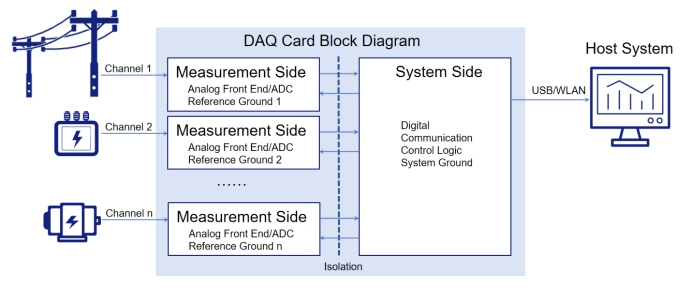

Channel-to-Channel Isolation

Definition: Each channel has a fully independent isolation domain and reference ground.

Each channel effectively functions as an independent isolated acquisition system, suitable for battery stacks, distributed measurements, and scenarios with large inter-channel potential differences, at the expense of higher cost, size, and system complexity.

Isolation Selection: From Parameters to Practical Judgment

After understanding isolation concepts, topologies, and voltage ratings, the key question becomes: does a given isolation design truly fit the application?

Many misjudgments arise from focusing on a single number such as “1000 V isolation” without clarifying where isolation is applied, for how long, and what additional protections are required.

What Is Being Isolated, and Where Does the Isolation Occur?

If all measurement objects belong to the same system and there is no potential difference between them, a Channel-to-System Ground Isolation data acquisition card should be selected.

If the measurement objects belong to multiple different systems, but the measurement points within each system share the same ground reference, a Bank Isolation (group isolation) architecture should be selected. In this case, measurement points from different systems must not be connected to the same bank of the acquisition card.

If all measurement objects belong to the same system but there are significant potential differences between them, a Channel-to-Channel Isolation data acquisition card should be selected.

This is the prerequisite for evaluating all isolation-related parameters.

If the isolation location is unclear, other voltage specifications are almost meaningless for comparison.

Isolation Withstand Voltage of a Data Acquisition System

At a minimum, the following information must be clearly specified:

whether the voltage is AC or DC, the duration (typically a 1-minute withstand test), and only then the voltage value itself.

If a data acquisition card specifies an AC isolation voltage of 1000 V, it means that an AC voltage with a peak value of ±1414 V is applied between the circuit grounds on both sides of the isolation barrier, and after 1 minute the leakage current remains below 0.1 mA.

If a data acquisition card specifies a DC isolation voltage of 1000 V, it means that a +1000 V or −1000 V DC voltage is applied between the circuit grounds on both sides of the isolation barrier, and after 1 minute the leakage current remains below 0.1 mA.

However, one must not assume that ±1000 V AC can be applied in this case—the two are not equivalent, because different devices have different withstand capabilities for AC and DC voltages.

It should be emphasized that the withstand voltages discussed above are short-term withstand ratings. They do not mean that the device can operate continuously at a 1000 V common-mode voltage. They only indicate that the device will not be damaged under those conditions, not that normal operation is guaranteed.

Maximum Common-Mode Operating Voltage

This is the parameter that deserves particular attention when selecting a data acquisition card. In most cases, it refers to the long-term voltage difference between the measurement side and the system ground.

For example, if we want to measure the current on a 220 V mains line, the corresponding common-mode voltage is:

220 V × 1.414 = 311 V

Allowing at least a 50% margin, the data acquisition card should therefore support a maximum common-mode operating voltage greater than 466 V.

If a specification sheet only provides isolation withstand voltage but does not clearly specify working voltage or maximum common-mode range, extreme caution is required in practical use.

Input Voltage Range

The input voltage range is also referred to as differential voltage. It defines how much voltage difference the input terminals of a channel can tolerate.

The key question is what happens when this limit is exceeded:

is the signal clipped, is the input shut down, or is permanent damage caused?

This parameter determines whether the device can protect itself under wiring errors or abnormal conditions, or whether it will fail catastrophically.

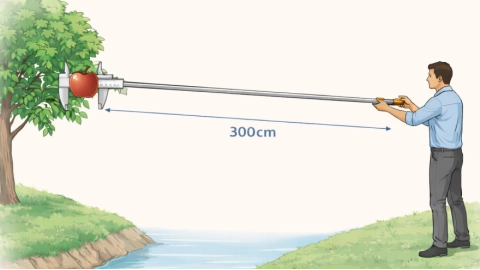

If the distinction between common-mode voltage and differential voltage is still unclear at this point, the following analogy may help.

In the diagram, the person cannot approach the apple directly because of the river acting as an isolation barrier, so a caliper with an extended handle is used to measure the apple on the opposite bank.

The 300 cm distance across the river corresponds to the common-mode voltage in the system, while the measurement range of the caliper (20 cm) corresponds to the differential voltage range.

Isolation Structure of the SonoDAQ Module (Bank Isolation Example)

After distinguishing between channel-to-ground isolation, bank isolation, and channel-to-channel isolation, as well as various isolation parameters, the next question for a specific product is: where exactly is the isolation boundary drawn?

The following figure shows the isolation structure of a SonoDAQ module, illustrating the division of its isolation domains.

From the module structure, it can be clearly seen that SonoDAQ Pro adopts a bank isolation architecture (see Section 6.2). Each module is isolated from the host, while the four channels on each module are not isolated from each other.

The module divides functionality and electrical domains into three parts:

- Measurement Side: Located on the left side of the module, directly connected to sensors and the device under test. This belongs to the measurement-side electrical domain and may be at a high or uncertain common-mode potential.

- Bank Isolation Domain: Located in the middle of the module, this is the primary isolation barrier between the measurement side and the system side. Multiple channels within the same bank share a common measurement-side reference ground and are collectively isolated from the system side through this isolation domain. As shown in the diagram, two types of isolation circuits are used: capacitive isolation for digital communication and magnetic (transformer-based) isolation for power.

- System Side: Located on the right side of the module, communicating with the host through the backplane. This side operates under system ground reference and connects to processors, communication interfaces, and the host computer.

From Concept to Verification: Isolation Must Be Proven, Not Assumed

Through the previous discussion, we have distinguished between differential and common-mode voltages and understood the respective roles of isolation withstand voltage, working voltage, and common-mode capability.

While these concepts are not complex in specifications or standards, a more critical question remains in real engineering practice:

Do these isolation boundaries actually hold under real-world conditions as the parameters suggest?

For example, when the device under test operates at a high common-mode potential, the acquisition system must run online for extended periods, and the host computer and operators must always remain on the safe side.

Simply “trusting a specification value” is far from sufficient. Rather than staying at the conceptual level, it is better to return to engineering practice. The following two experiments are not intended to demonstrate extreme parameter limits, but to address a more practical question.

For this purpose, SonoDAQ Pro was selected as the test platform—not because of exceptionally high specifications, but because its isolation structure is clear and its boundaries are well defined, making it suitable for engineering-level isolation verification.

The experiments are conducted from two perspectives: withstand voltage testing (hipot) and mains-powered incandescent lamp current measurement.

Withstand Voltage Test (Hipot)

Test objective:

To verify that the isolation barrier can withstand high voltage under specified conditions without breakdown, providing an intuitive engineering verification result

The general industry definition of dielectric withstand testing is to apply an elevated voltage across an insulation barrier for approximately 1 minute. Passing the test indicates that the insulation system has sufficient electrical strength under those conditions, while also clarifying the purpose and limitations of the test to avoid misinterpretation.

Test equipment:

WB2671 hipot tester

Test conditions:

1000 V DC, duration 1 minute, leakage current threshold 0.1 mA

Test Results

1.02 kV DC, duration 1 minute, leakage current = 0.03 mA, with no breakdown, flashover, or arcing observed.

Explanation: SonoDAQ Pro adopts a bank isolation architecture, where the six slots are isolated from each other. Therefore, during testing, the hipot voltage was applied between Channel 1 of two adjacent modules.

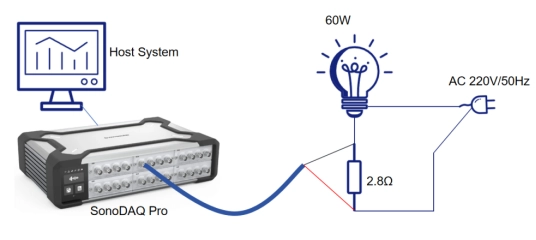

220 V Mains Incandescent Lamp Current Measurement Experiment

Test objective:

To demonstrate how the data acquisition card can measure signals in a high-voltage system under real mains conditions, and to verify measurement correctness.

Why an incandescent lamp?

- Its steady-state behavior closely resembles a resistive load, making current waveforms intuitive and easy to interpret.

- The cold filament has low resistance, producing a clear inrush current at power-on, which is suitable for demonstrating transient capture and trigger recording capability.

In the diagram, the left side is the high-voltage area directly connected to the 220 V AC source. After all wiring is completed, the power plug is inserted.

The right side contains the isolated data acquisition card, forming the low-voltage area. The computer and operator remain entirely on the safe side.

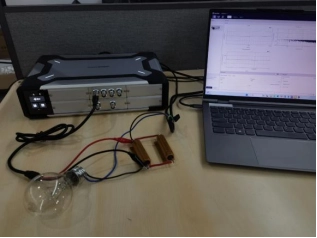

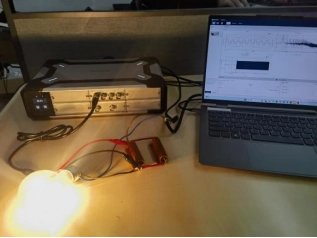

The experiment used SonoDAQ Pro hardware with OpenTest software. The incandescent lamp was rated at 220 V / 60 W.

The following photos show the setup before power-on (left) and after power-on (right).

|  |

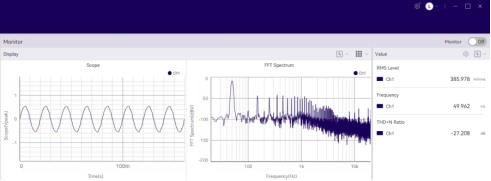

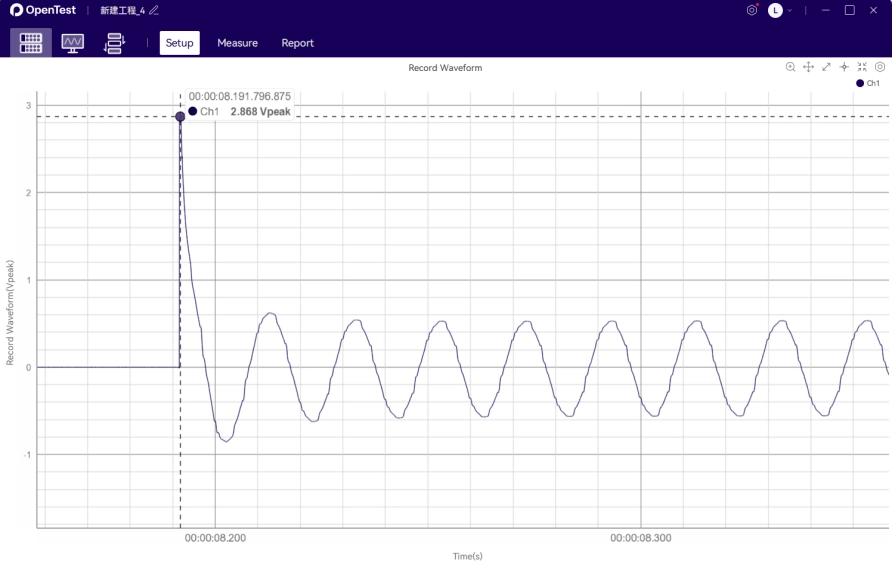

Test configuration: sampling rate 192 kSa/s, AC coupling for the input signal. The acquisition card directly measured the voltage across a 1.4 Ω shunt resistor. Using the “Record” function in OpenTest, the entire power-on and power-off process was recorded.

Steady-state current:

Vrms = 386 mV → Irms = 386 / 1.4 = 275.7 mA

Frequency f = 49.962 Hz

Startup current:

Vpeak = 2.868 V → Ipeak = 2.868 / 1.4 = 2.05 A

Crest factor calculation:

CF = Ipeak / Irms = 2.05 / 0.2757 = 7.44

Incandescent lamp power calculation:

P = 220 V × 0.2757 A = 60.65 W

Conclusion

SonoDAQ Pro can accurately measure the operating current of an incandescent lamp connected directly to the mains without using a current transformer.

This experiment does not merely verify whether mains signals can be measured; it verifies whether isolation can simultaneously ensure system safety and measurement accuracy when the device under test operates at a high common-mode potential over extended periods.

Isolation Is Not a Parameter, but a Boundary

Isolation is not “a single voltage value,” but rather defines where risk is confined and whether signals can still pass reliably.

A reliable isolation solution is the result of structure, parameters, topology, and application scenario all being valid at the same time.

To see more imformation about the SonoDAQ, please fill in the form below, and we will recommend the best solution to address your needs.

Related Products

SonoDAQ Pro

OpenTest

CRY3018 Sound Calibrator

Get in touch

If you are interested or have questions about our products, book a demo and we will be glad to show how it works, which solutions it can take part of and discuss how it might fit your needs and organization.