Measure Sound Better

Automotive HVAC Air Vent EoL Test Case

Table of content

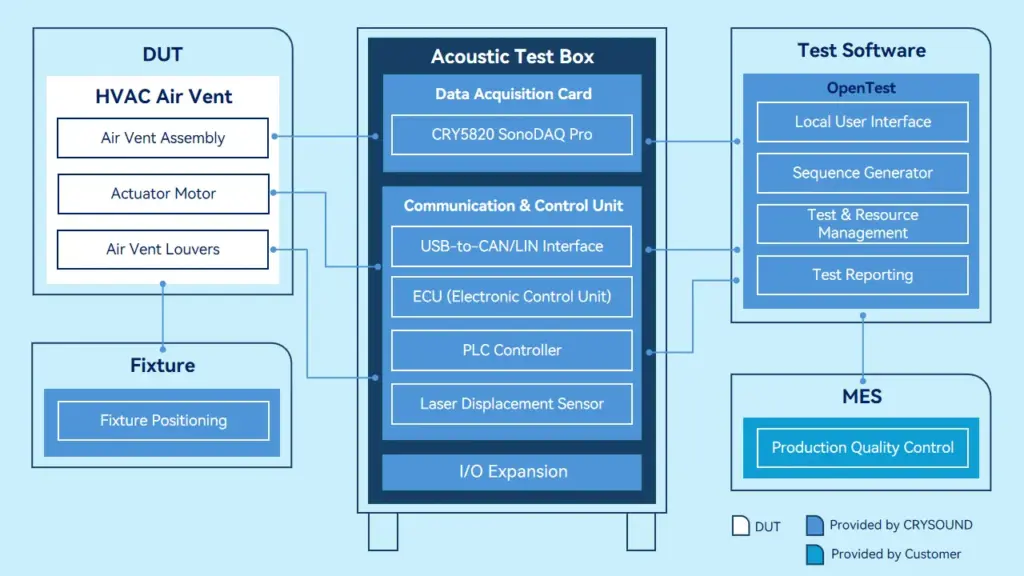

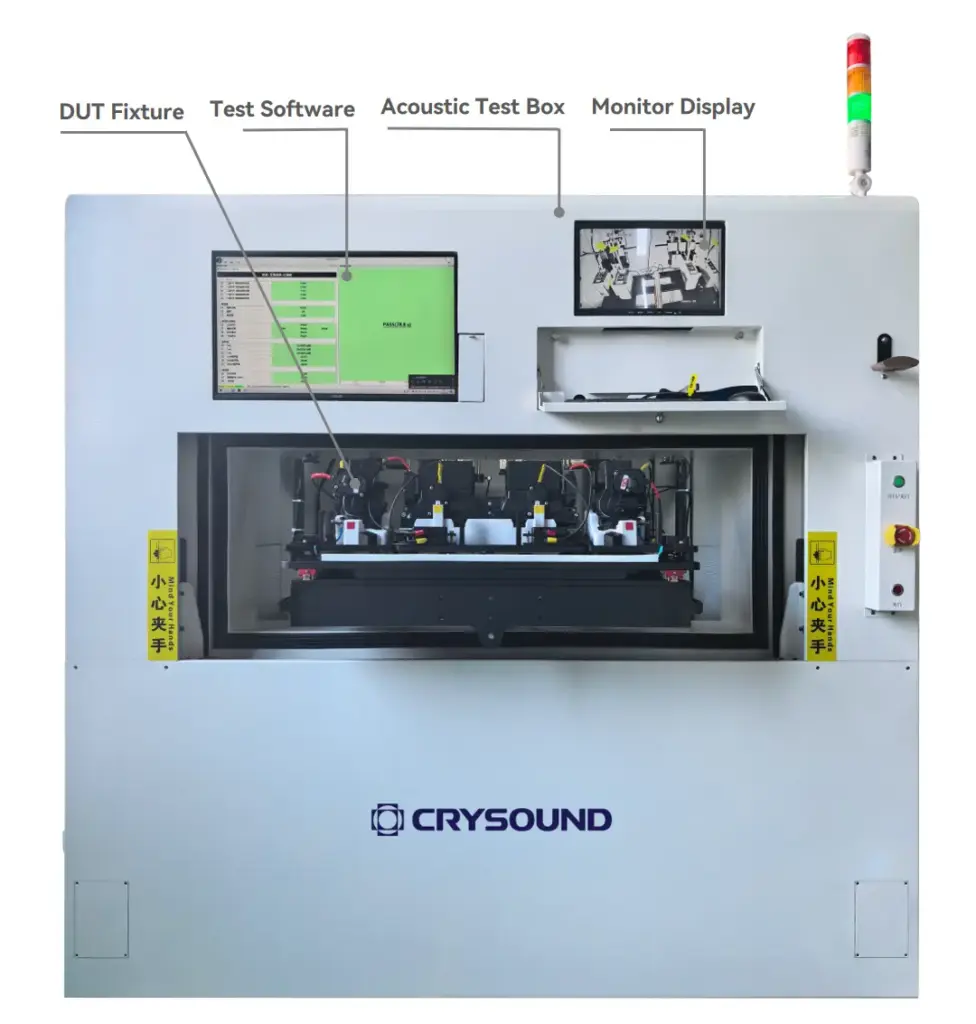

This integrated single-station EoL test solution enables automotive HVAC air vent suppliers to perform NVH (noise/BSR), motor electrical testing, and vane presence detection in a single inspection step, helping to improve overall test efficiency and reduce labor dependency.

Modern automotive HVAC air vent assemblies increasingly integrate multiple drive motors, multi-row vanes (louvers), and smart features such as automatic airflow control and voice interaction. As a result, upstream process variation or assembly defects can translate directly into vehicle-level concerns—typically perceived as abnormal noise, buzz/squeak/rattle (BSR), airflow direction mismatch, or reduced airflow caused by missing/misassembled vanes.

To reduce rework and prevent customer complaints, suppliers increasingly require 100% end-of-line (EoL) testing on the production line, covering NVH (noise/BSR), motor electrical testing, and vane presence detection.

CRYSOUND Single-Station EoL Test Solution

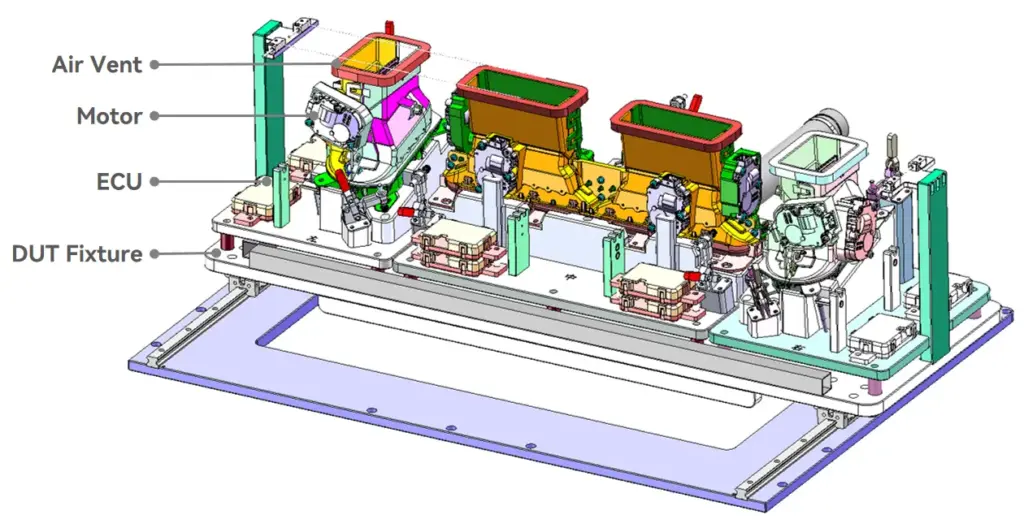

CRYSOUND's automotive HVAC air vent EoL test solution enables customers to perform single-station, 100% testing of noise/BSR, motor electrical testing, and vane presence detection.

The solution integrates CRYSOUND's in-house hardware and software, CRY3203-S01 measurement microphone set, SonoDAQ, CRY7869 acoustic test box, and OpenTest. And it combines electroacoustic measurement with abnormal noise analysis (sound quality and AI-based algorithms) to identify noise/BSR issues that FFT and Leq may miss. It also integrates motor electrical testing and vane presence detection, enabling one-time clamping and a single OK/NG decision within the same sound-insulated EoL station.

Customer Results: Efficiency, Labor, and Quality Gains

- Replaced manual listening with machine-based detection, enabling unified criteria with quantitative, traceable results.

- One fixture, three test positions: supports parallel or mixed testing of left/center/right dashboard air vents, improving efficiency by >100%.

- Variant support via fixture changeover: reuse the same test station across different products, reducing repeated capital investment.

- One-operator, one-click inspection: a single line can save 1–2 long-term operators.

Typical Target Users

This solution is designed for suppliers of motorized air vents and other motor-driven interior components,such as Valeo S.A.,Ningbo Joysonquin Automotive Systems Co., Ltd. and Jiangsu Xinquan Automotive Trim Co., Ltd.

Main Hardware and Software Configuration

| Product | Qty. | Note |

|---|---|---|

| CRY3203-S01 Measurement Microphone Set | 1 | Measurement Microhone Set |

| CRY5820 SonoDAQ Pro | 1 | Audio Analyzer |

| CRY7869 Acoustic Test Box | 1 | Test Environment |

| OpenTest http://www.opentest.com | 1 | Software |

| Fixture | 1 | Customizable |

| PC & Monitor | 1 | (Optional) |

Feel free to fill in the form below ↓to contact us. Our team can share application-specific EoL testing recommendations based on your automotive HVAC air vent requirements.

Related Products

SonoDAQ Pro

CRY3201-S01 Free-Field Microphone Set, 1/2", 12.5mV/Pa

CRY725 Pneumatic Acoustic Test Chamber

OpenTest

CRY3018 Sound Calibrator

Get in touch

If you are interested or have questions about our products, book a demo and we will be glad to show how it works, which solutions it can take part of and discuss how it might fit your needs and organization.