Measure Sound Better

Anechoic Chamber Explained: Types, Design Standards, and How to Test Without One

Table of content

What Is an Anechoic Chamber?

An anechoic chamber is a room designed to completely absorb sound reflections. The walls, ceiling, and (in a full anechoic chamber) the floor are lined with wedge-shaped foam or fibreglass absorbers that prevent sound waves from bouncing back into the room.

The result is a controlled acoustic environment that simulates free-field conditions — as if the sound source were suspended in open air with no surfaces nearby.

This matters because most acoustic measurements — sound power, directivity, frequency response — require a known, reflection-free environment to produce repeatable, standards-compliant results. Without it, room reflections contaminate the measurement, making results dependent on the specific room rather than the product being tested.

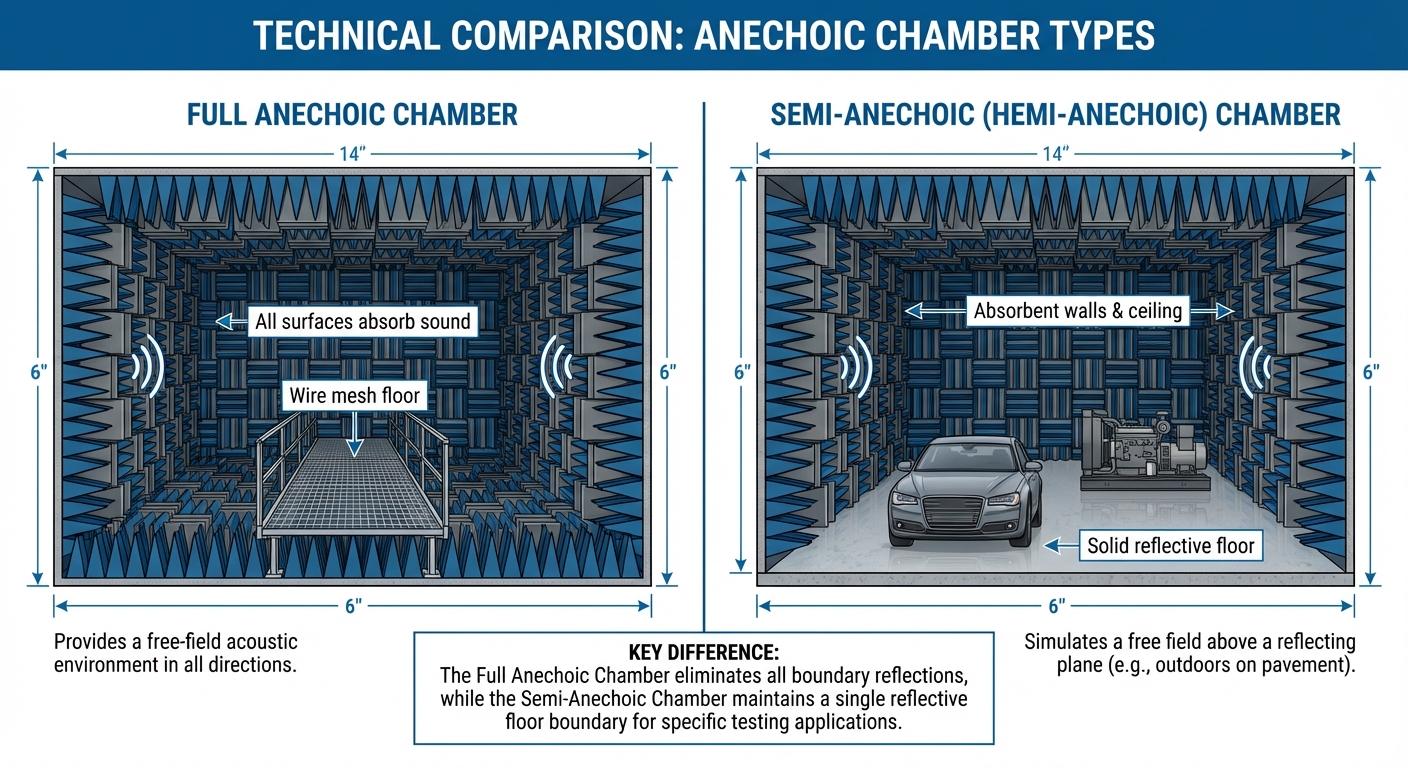

Full Anechoic vs Semi-Anechoic (Hemi-Anechoic) Chambers

| Feature | Full Anechoic | Semi-Anechoic (Hemi-Anechoic) |

|---|---|---|

| Absorbing surfaces | All 6 surfaces (walls, ceiling, floor) | 5 surfaces (walls + ceiling); floor is reflective |

| Floor | Wire mesh or perforated metal grid suspended above absorbers | Solid, load-bearing concrete or steel |

| Acoustic condition | Free-field (no reflections from any direction) | Free-field over a reflecting plane |

| Load capacity | Limited — cannot support heavy equipment directly | Can support vehicles, machinery, industrial equipment |

| Primary standards | ISO 3745 (precision sound power) | ISO 3744 (engineering sound power), ISO 3745 |

| Typical use | Microphone calibration, loudspeaker characterisation, hearing research | Automotive NVH, product noise testing, industrial machinery |

| Cost | Higher (floor treatment adds significant cost and complexity) | Lower (no floor treatment needed) |

In practice, about 80% of industrial acoustic testing uses semi-anechoic chambers because most test objects — cars, appliances, compressors, power tools — are too heavy for a suspended wire-mesh floor.

What Standards Require an Anechoic Chamber?

ISO 3745 — Precision Sound Power Measurement

The gold standard for sound power determination. Requires either a full anechoic or hemi-anechoic chamber qualified to meet strict free-field deviation limits across the frequency range of interest. The chamber must demonstrate that the inverse-square law holds to within ±1 dB at the measurement positions.

Typical cut-off frequency: 80–200 Hz, depending on chamber size and wedge depth. Below this frequency, the chamber no longer behaves as a free field.

ISO 3744 — Engineering Sound Power Measurement

Less stringent than ISO 3745 but still requires a hemi-anechoic environment. Allows for environmental corrections when the room is not perfectly anechoic, making it practical for production-floor test cells that approximate (but do not perfectly achieve) free-field conditions.

ISO 26101 — Qualification of Free-Field Environments

Defines how to verify whether a room actually meets free-field requirements. This is the standard used to “qualify” an anechoic or hemi-anechoic chamber — confirming that its acoustic performance matches what is claimed.

Other Standards

- ECMA-74: IT equipment noise measurement (uses ISO 3745 or ISO 3744 as the underlying acoustic method)

- ANSI S12.55 / S12.56: North American equivalents of ISO 3744/3745

- ISO 11201–11205: Various sound pressure level determination methods, some requiring free-field conditions

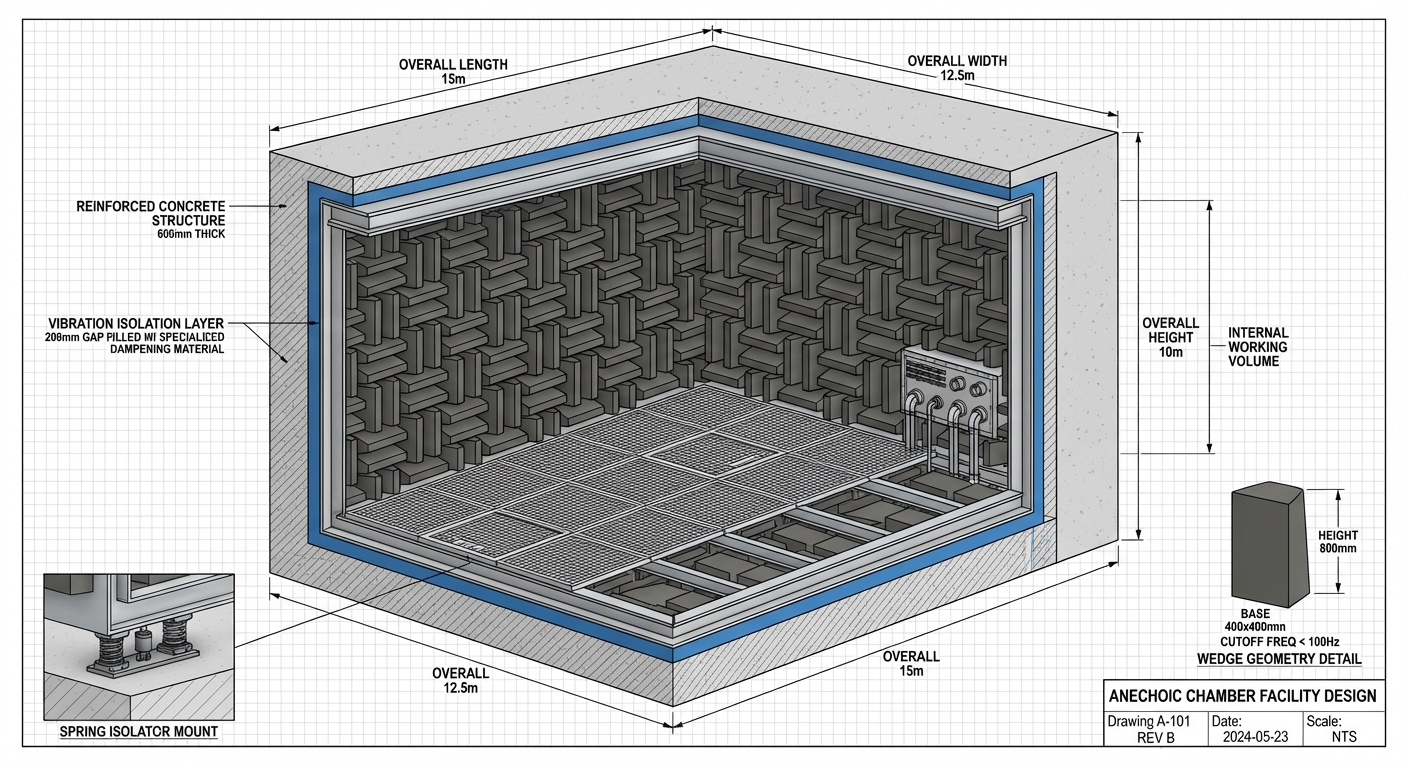

Key Design Considerations

1. Chamber Size and Usable Volume

The physical dimensions determine the lowest usable frequency. A general rule: the chamber must be large enough that the distance between the sound source and each measurement microphone is at least one wavelength at the lowest frequency of interest.

For a 100 Hz cut-off, the minimum source-to-microphone distance is approximately 3.4 metres, which means the chamber's internal dimensions (excluding wedges) should be at least 7–8 metres per side for a hemi-anechoic chamber.

2. Wedge Absorbers

The depth of the absorbing wedges determines the low-frequency performance. Deeper wedges absorb lower frequencies:

| Wedge Depth | Approximate Low-Frequency Cut-off |

|---|---|

| 200 mm | ~500 Hz |

| 500 mm | ~200 Hz |

| 1000 mm | ~80–100 Hz |

Wedge materials include melamine foam (lightweight, fire-retardant) and fibreglass (better low-frequency absorption but heavier).

3. Background Noise

An anechoic chamber must also be well-isolated from external noise. The ambient noise level inside the chamber (with no source operating) should be at least 6 dB — and preferably 15 dB — below the sound pressure level generated by the test object at the measurement positions.

This typically requires a chamber built with multiple layers of massive construction (concrete, steel) and vibration-isolated mounting to prevent structure-borne noise transmission.

4. Vibration Isolation

For NVH testing (especially automotive), the chamber floor may include vibration-isolated foundations or air-spring mounting systems to prevent road-simulator or dynamometer vibrations from coupling into the acoustic measurement environment.

What If You Do Not Have an Anechoic Chamber?

Not every organisation can invest $500K–$2M+ in a purpose-built anechoic facility. Several practical alternatives exist:

Sound Intensity Method (ISO 9614)

Sound intensity measurements are inherently less sensitive to room reflections because intensity is a vector quantity — it distinguishes between outgoing sound (from the source) and incoming sound (reflections from room surfaces). This allows sound power determination in ordinary rooms without anechoic treatment.

Trade-off: Requires specialised intensity probes and more complex measurement procedures.

Acoustic Test Boxes

For small products (electronics, components, transducers), a desktop-sized acoustic test box provides a controlled, low-noise environment that approximates anechoic conditions within a defined frequency range. These are significantly cheaper than a full chamber and can be placed directly on a production line.

CRYSOUND offers a comprehensive range of acoustic test chambers designed for different testing scenarios:

- CRY723 Pneumatic Acoustic Test Chamber — A compact, shell-type test box ideal for smartphones and wireless wearables. Combine two CRY723 units with a CRY6151B analyzer for complete audio, ENC, and ANC measurements.

- CRY725 Pneumatic Acoustic Test Chamber — Designed for larger wireless devices such as laptops and walkie-talkies. Compatible with comprehensive testers and vector network analyzers.

- CRY7865 Pneumatic Acoustic Test Chamber — A high-performance drawer-style chamber with both acoustic isolation and RF shielding, ideal for production line audio and noise measurements of wireless electronic devices.

- CRY7412 Ultra-Quiet Chamber — An ultra-quiet chamber for testing very quiet sounds in noisy environments. Features a unique double-shell design for superior noise isolation.

All models support pneumatic operation for fast, repeatable DUT loading on production lines — a practical alternative when a full anechoic chamber is not justified by the application.

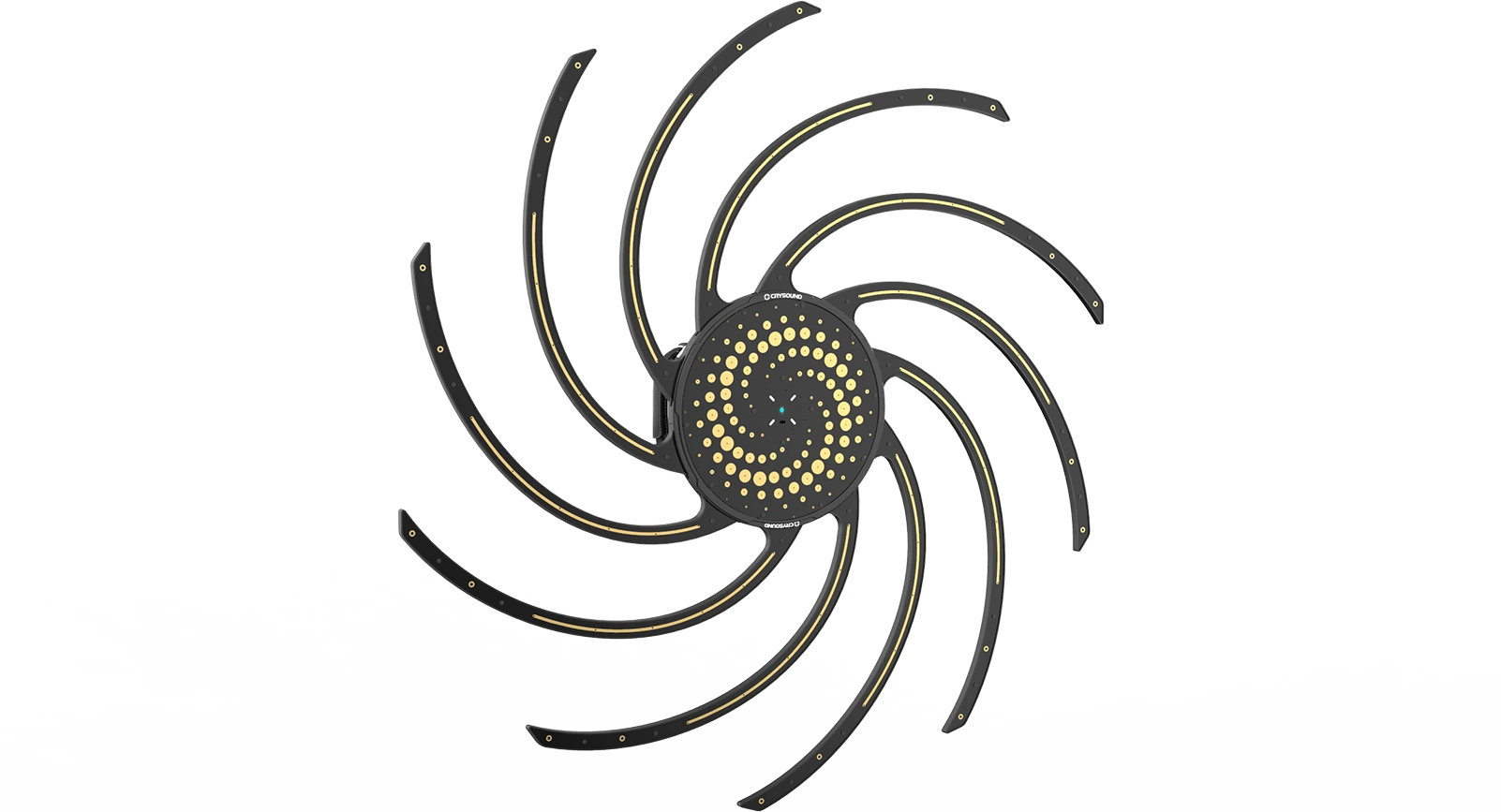

Portable Acoustic Arrays

Modern acoustic imaging cameras can identify and localise noise sources in situ — in the factory, on the production line, or in the field — without any anechoic treatment. While not a substitute for standards-compliant sound power measurements, acoustic imaging enables rapid noise source diagnosis that previously required dedicated chamber time.

The CRY8500 Series SonoCam Pi Acoustic Camera, is a portable acoustic imaging camera that delivers real-time sound source visualisation — ideal for R&D engineers working on noise source identification in automotive NVH, industrial equipment, and consumer electronics.

In-Situ Sound Power (ISO 3744 with Corrections)

ISO 3744 allows environmental correction factors to account for room reflections. If the correction is small (typically less than 2 dB), the measurement can be performed in a reasonably quiet industrial space without a purpose-built chamber.

The SonoDAQ Pro data acquisition system combined with OpenTest software supports automated sound power calculations with environmental corrections built in — enabling standards-compliant measurements without a dedicated anechoic chamber.

Frequently Asked Questions

How much does an anechoic chamber cost?

Costs vary widely based on size, performance requirements, and cut-off frequency. A small hemi-anechoic room for component testing may start around $100K–$300K, while a large automotive-grade full anechoic chamber can exceed $2M. For smaller products, acoustic test boxes offer similar isolation at a fraction of the cost.

What is the difference between an anechoic chamber and a soundproof room?

A soundproof room blocks external noise from entering but does nothing about internal reflections. An anechoic chamber both blocks external noise and absorbs internal reflections, creating a free-field environment for precision measurement.

Can I do acoustic testing without an anechoic chamber?

Yes. Depending on your application, alternatives include acoustic test boxes for small products, sound intensity methods (ISO 9614), portable acoustic imaging cameras like the CRY8500 SonoCam Pi, and in-situ measurements with environmental corrections using systems like SonoDAQ Pro.

What frequency range does an anechoic chamber cover?

The usable frequency range depends on the wedge depth and chamber dimensions. Most chambers are effective from their cut-off frequency (typically 80–200 Hz) up to 20 kHz or beyond. Below the cut-off, the chamber no longer provides adequate absorption.

How is an anechoic chamber qualified?

Chamber qualification follows ISO 26101, which verifies that the inverse-square law (sound pressure decreasing by 6 dB per doubling of distance) holds within specified tolerances at the measurement positions.

Conclusion

Anechoic chambers remain the gold standard for precision acoustic measurement — but they are not the only option. Understanding what your application truly requires helps you choose the right solution, whether that is a full anechoic room, a compact acoustic test chamber, or an in-situ measurement approach.

At CRYSOUND, we provide the full spectrum: from purpose-built anechoic chambers to portable acoustic test boxes and advanced measurement systems — so you can get accurate results regardless of your facility constraints.

Contact us to discuss which solution fits your testing requirements.

Related Products

Anechoic Chamber

CRY2851 Sound Level Meter

SonoDAQ Pro

CRY8500 Series SonoCam Pi Acoustic Camera

OpenTest

CRY7413 Acoustic Test Chamber, Manual Door

CRY721C Pneumatic Acoustic Test Chamber

CRY723 Pneumatic Acoustic Test Chamber

CRY7865 Pneumatic Acoustic Test Chamber

CRY7412 Ultra-Quiet Chamber

CRY710 Pneumatic Acoustic Test Chamber

Get in touch

If you are interested or have questions about our products, book a demo and we will be glad to show how it works, which solutions it can take part of and discuss how it might fit your needs and organization.