Measure Sound Better

A²B Microphone Testing: A Practical Measurement Setup and Workflow

Table of content

As A²B microphones and sensors are increasingly adopted in automotive applications, the demand for reliable testing in both R&D and production is also growing. This article explains why A²B testing matters, highlights the advantages of A²B over traditional analog cabling in terms of interconnect and scalability, outlines key measurement KPIs (such as frequency response, THD+N, phase/polarity, and SNR), and presents a typical test-bench setup along with the corresponding solution configuration.

Why A²B Microphone and Sensor Testing Matters

In-cabin audio is no longer just "music playback". Modern vehicles depend on high-performance acoustic sensing for hands-free calling, in-cabin communication, voice assistants, ANC/RNC, and more—and these features increasingly rely on multiple microphones and even accelerometers deployed around the cabin. ADI notes that the rapid expansion of audio-, voice-, and acoustics-related applications is a key trend, and that new digital microphone and connectivity approaches are enabling broader adoption.

To deliver consistent performance, teams need a test workflow that is repeatable across different node positions, harness lengths, and configurations—without turning every debug session into a custom project.

The Interconnect Shift: From Shielded Analog Cables to Digital A²B

Historically, scaling microphone counts often meant scaling shielded analog cabling, which adds weight, cost, and integration burden—sometimes limiting these features to premium vehicle segments.

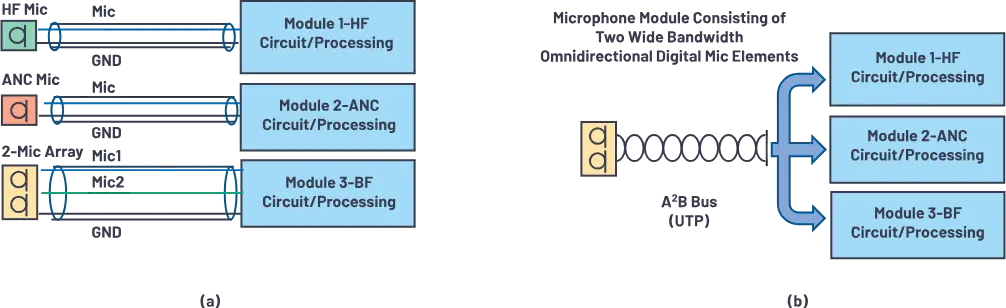

A²B (Automotive Audio Bus) addresses that interconnect problem by enabling a scalable, networked digital audio architecture with deterministic behavior—exactly what timing-sensitive acoustic applications need. Figures a and b show how such a design may be realized with the traditional analog and the digital A²B systems, respectively.

(b) Digital system design with digital mic elements (A²B technology and UTP wires).

What You'll Measure: Key A²B Microphone KPIs

- Frequency Response (FR)

- THD+N

- Phase / polarity (and channel-to-channel consistency for arrays)

- SNR

- AOP (if required by your program/spec)

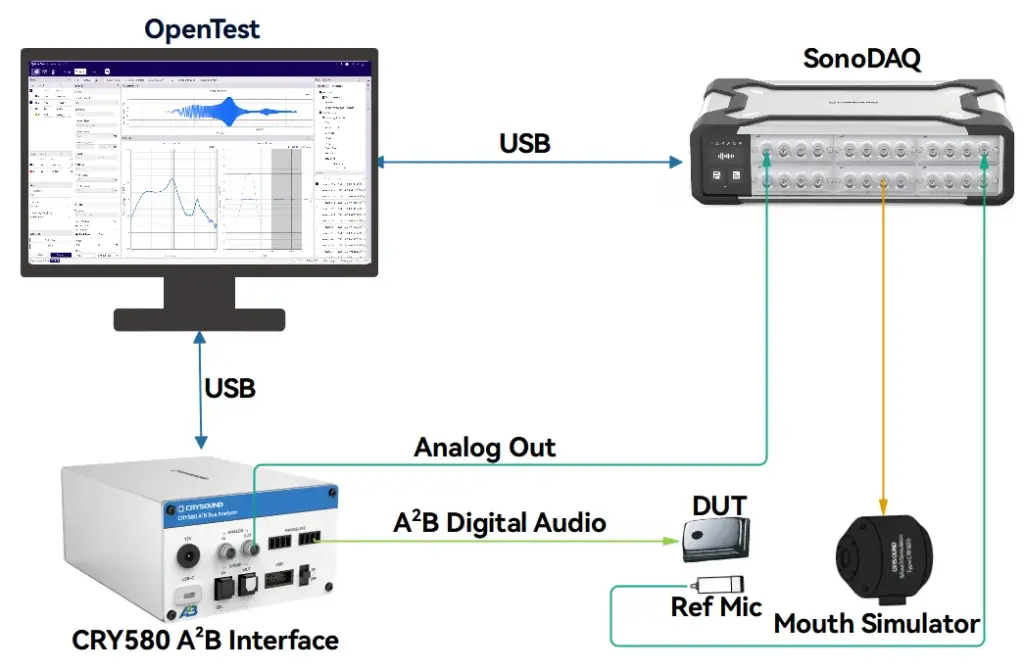

Typical Block Diagram-What the Bench Looks Like

At CRYSOUND, we provide more than just the CRY580 A²B interface. We offer a full automotive audio testing solution, including audio acquisition cards, microphones and sensors, acoustic sources, custom fixtures, acoustic test boxes, and vibration shakers, delivering a complete and streamlined testing experience.

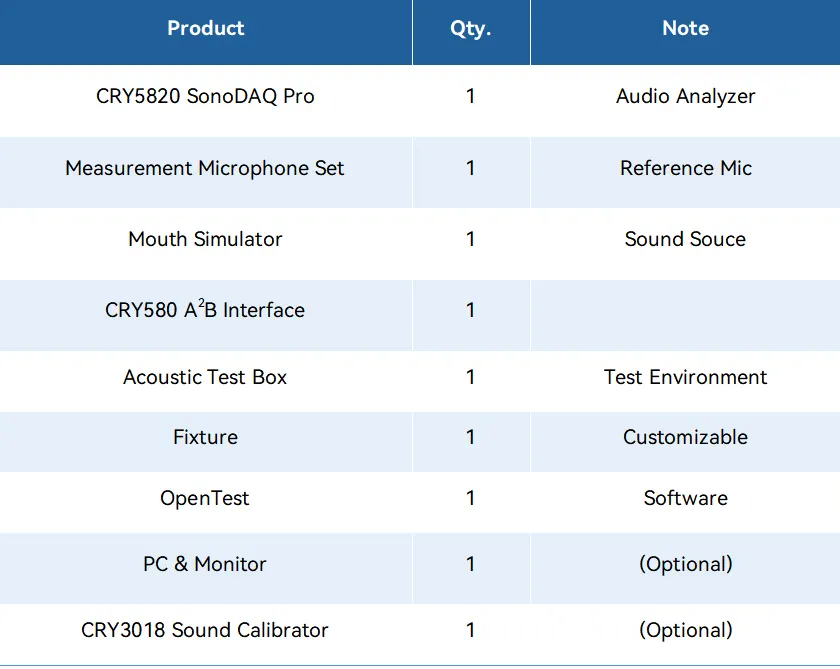

Solution BOM List

The value of end-to-end delivery: reducing system integration time and minimizing coordination costs between multiple suppliers. We cover everything from R&D to production line testing.

If you'd like to learn more about A²B testing, please fill out the Get in touch form below and we'll reach out shoutly.

Related Products

CRY580 A²B Interface

SonoDAQ Pro

OpenTest

Get in touch

If you are interested or have questions about our products, book a demo and we will be glad to show how it works, which solutions it can take part of and discuss how it might fit your needs and organization.