Measure Sound Better

Gas Leak Detection in Ordinary Scenarios

Identify Gas Leaks at a Glance

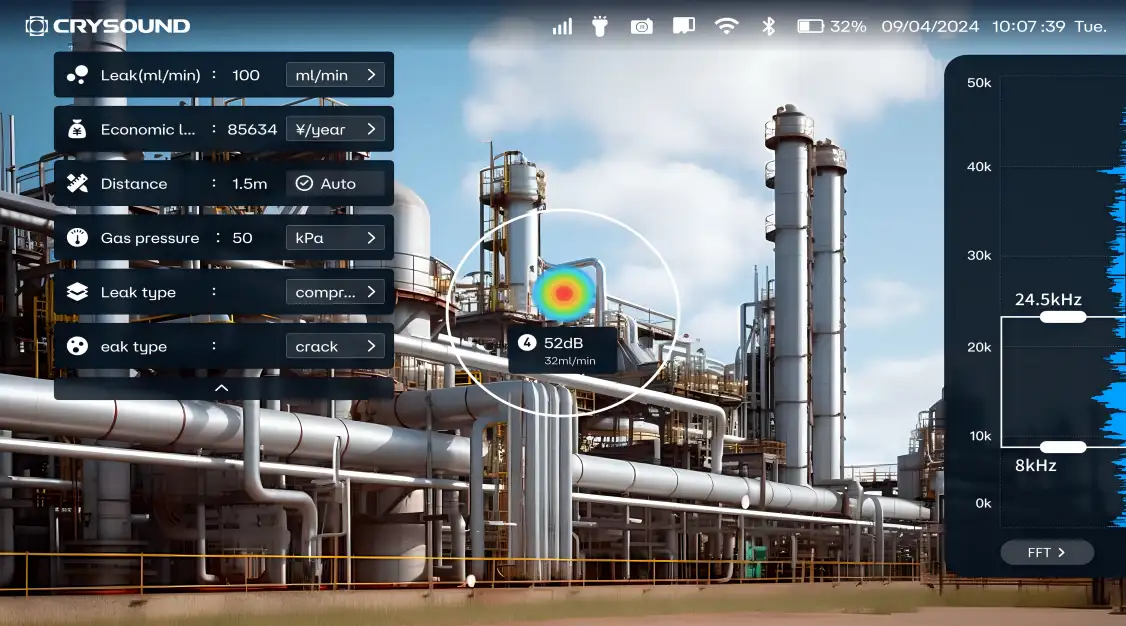

The acoustic camera transforms sound waves emitted by leaking gases into visual representations, overlaying them onto live video feeds. With its ability to cover extensive distances and a broad field of view, the acoustic camera facilitates rapid response to address the issue efficiently.

Locate leaks in real-time

As the camera scans the area, it instantly visualizes the location of leaks on the screen

Works for all gas types

By detecting sound waves generated by gas leaks, the device can located any type of gas

Pinpoint the Tiniest Leaks

In industrial settings where even a minor leak can have significant consequences in terms of safety, environmental impact, and financial costs, early detection is crucial. By detecting leaks at their earliest stages, acoustic cameras empower industrial operators to take proactive measures to mitigate risks and minimize the potential impact on operations.

Excludes noise with mic array

Background noise and other irrelevant sounds are excluded by beamforming of microphone array

0.32 ml/s under 0.5 m 5 bar

With a minimum leak detection capability of 0.32 ml/s, acoustic camera covers the majority industrial gas scenarios

Prioritize Safety

The protection of personnel and assets are the top priority for industrial facilities. The acoustic camera allows for inspections from a safe distance, ensuring that operators stay out of harm's way.

Far-field and non-intrusive

With a working distance from 0.5 – 150 m, the acoustic camera eliminates exposure to harmful gases and the need for personnel to scale scaffolding

Intrinsically safe

The ATEX certificate assures safety in hazardous zones, eliminating the possibility of sparking or causing explosions

Minimal Training Requirements

Other gas leak detection solutions on the market require specialized training to interpret images, distinguish between true leaks and false positives, and navigate complex industrial environments. With sophisticated acoustic camera technology, users quickly learn how to operate the device, saving time and reducing frustration.

Intuitive display

The screen of the acoustic camera presents vivid images with a touchscreen interface

No experts needed

The device is user-friendly, requiring little training to operate.

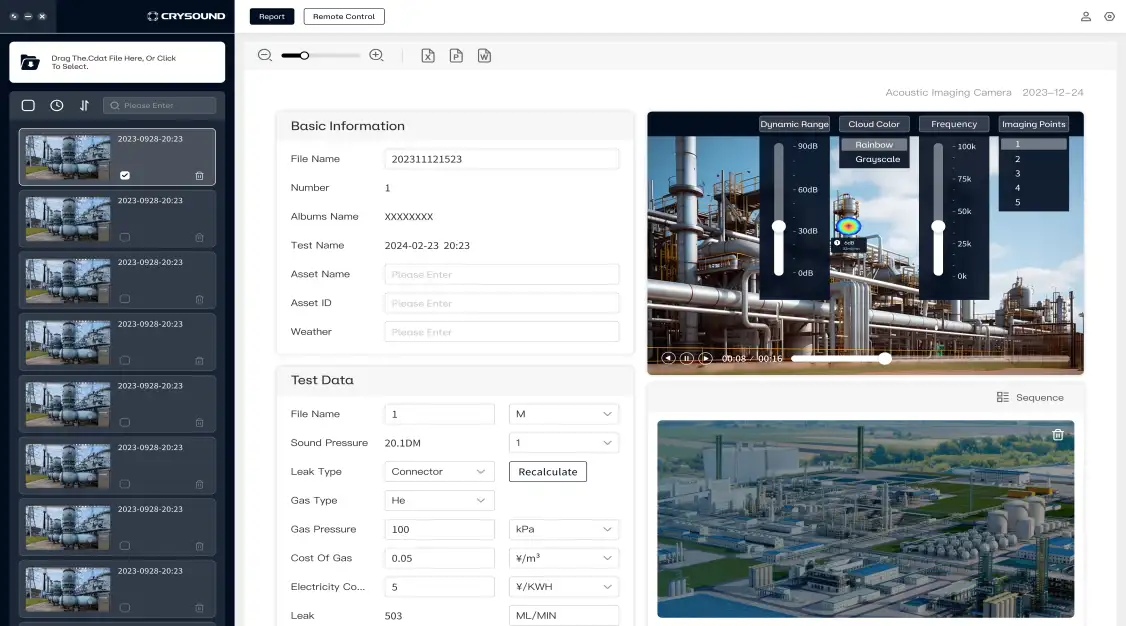

Measure Leaks, Measure Cost

The acoustic camera uses advanced algorithms to quantify leaks by analyzing factors such as sound pressure levels, distance, leak type, and other characteristics of escaping gases. By accounting for variables like gas type, market value, and energy costs, the camera calculates the economic impact, enabling more informed decision-making.

See the cost of leaks

Based on the measured dB SPL value, the acoustic camera calculates the leak rate and economic loss of each leak

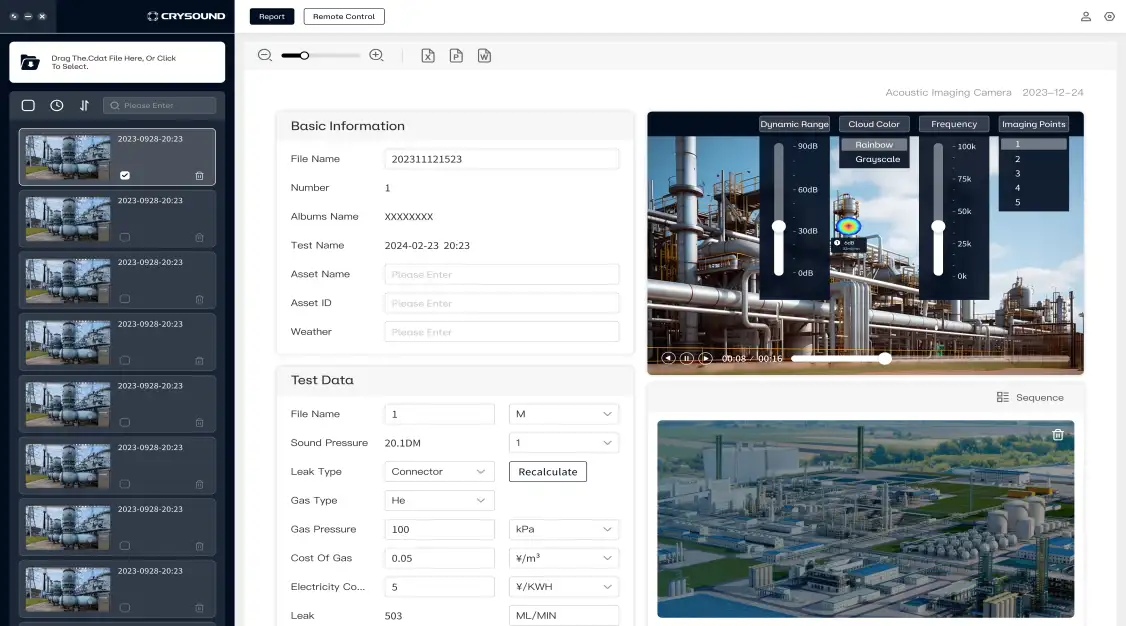

Streamline the reporting process

With the reporting tool, data can be shared among teams to prioritize repairs, and optimize resource allocation

System Devices

CRY8124 Advanced Acoustic Imaging Camera

CRY2620 64-Mic Industrial Acoustic Imaging Camera

CRY2623 128-Mic Industrial Acoustic Imaging Camera

Explore More Cases

Get in touch

If you are interested or have questions about our products, book a demo and we will be glad to show how it works, which solutions it can take part of and discuss how it might fit your needs and organization.