Advanced Inspection

System Integrating

Acoustic and

Infrared Imaging

A complete detection

solution for detecting PD

Audiovisual, Infrared & Analog Input

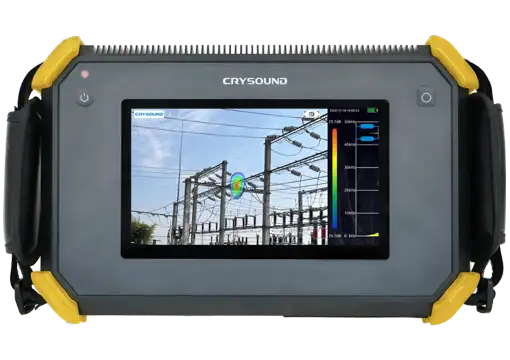

The latest generation acoustic camera, the CRY8120 Series, features 200 MEMS microphones and a 200kHz sampling rate. In partial discharge (PD) detection, it can precisely pinpoint even the smallest fault points, display real-time PRPD maps, identify discharge types, and deliver highly accurate assessments of equipment operational status. Additionally, the device supports infrared modules and analog signal inputs, with plans for future compatibility with a broader range of sensors.

A microphone array with up to 200 channels

The upgraded microphone array brings higher accuracy in detecting PD.

An all-in-one solution

The CRY82120 series is a complete solution with infrared modules and analog sensor input.

how do I hear the ultrasound audio?

The device retains the sound monitoring function of traditional ultrasonic detection equipment, processes the received ultrasonic signals using an algorithm of amplification, frequency reduction, volume adjustment, and power amplification processing, and eventually produces audio signals that can be heard by the human ear. The user can insert 3.5mm interface headphones to observe the strange sound source.

Makes fault determination more intuitive

You can listen to the audio signal to assess its features; a partial discharge of the audio will produce a distinct discharge sound.

Widening the hearing threshold of the ear

Through a variety of audio processing procedures, the human ear can perceive ultrasonic waves.

Combining multiple sensors in one inspection device

The Acoustic Imaging Camera preserves both type-C and analog signal ports to allow access to different sensors. When a single sensor cannot be adequately examined, it is feasible to switch to another sensor that is more suited to the current situation.

Efficient Detection

The Acoustic Imaging Camera is an extremely effective inspection tool due to its multi-sensor access.

Reduced equipment costs

One device can perform the detection function of numerous devices, eliminating the need to purchase several devices.

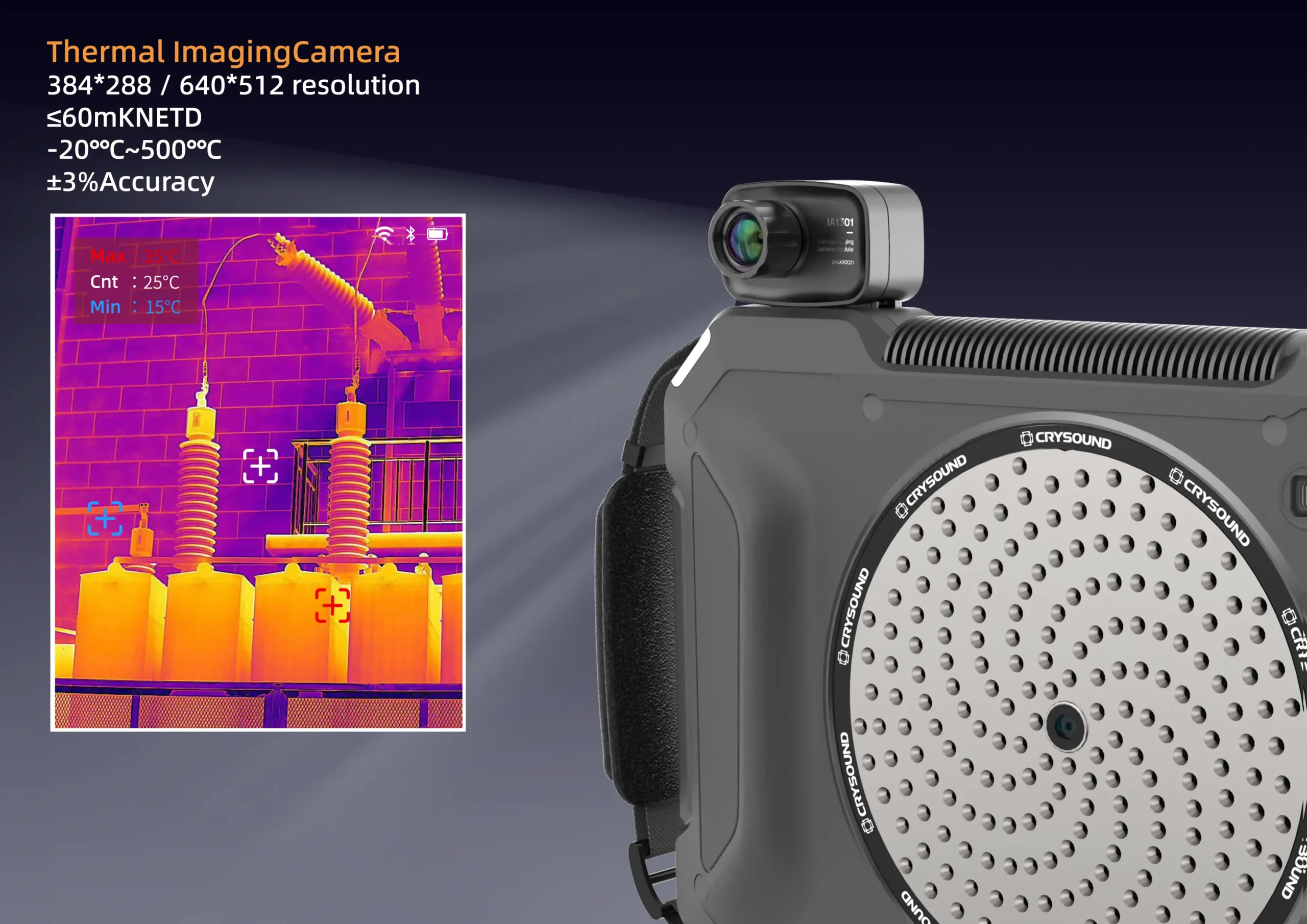

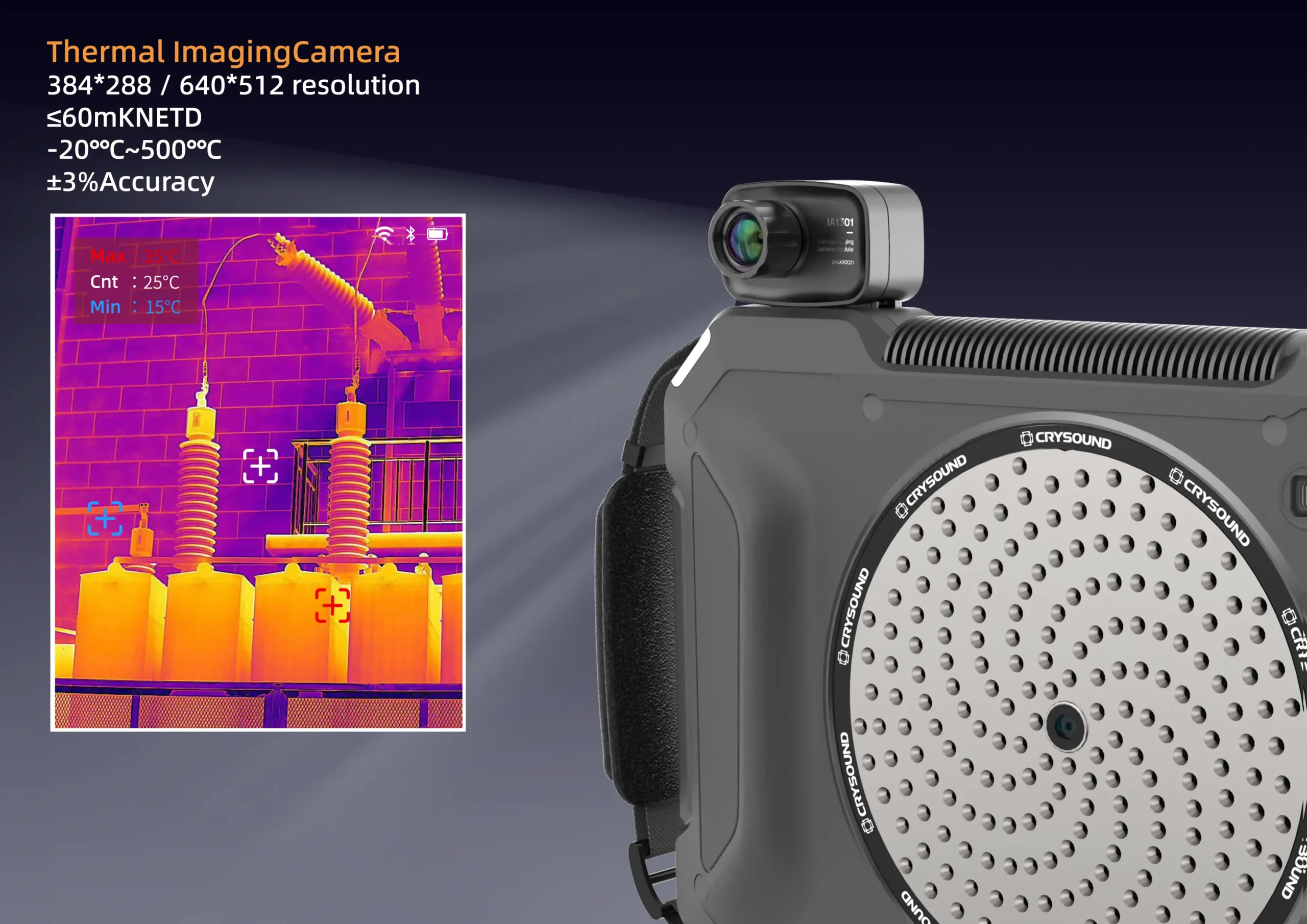

Acoustic imaging & infrared capabilities for additional testing instruments

The sound Imaging Camera transformed the infrared module by increasing its ability to collect temperature data while doing sound testing on equipment. In power system testing, partial discharges and overheating defects can be detected simultaneously.

Hot-plug infrared module

The gadget connects to the infrared module via the type-C interface, which is both convenient and efficient to operate.

Support split-screen display for infrared acoustic imaging

Infrared and acoustic imaging are displayed on the same screen, enabling for a more intuitive and detailed evaluation of power equipment condition.

Explore More Use Cases

Within the intricate tapestry of electrical systems, where the paramount significance of ensuring power distribution safety and reliability cannot be overstated, the swift detection and mitigation of partial discharge (PD) emerge as critical elements in averting equipment degradation and voltage instabilities. Acknowledging this pressing need, our discerning clients frequently seek insights into the practical applications of acoustic imaging technology to address PD challenges. In response to this demand, the CRYSOUND team takes pride in presenting a series of compelling case studies that highlight the precise utilization of acoustic imaging cameras across two pivotal domains: substations and power distribution systems.

Application Scene: Electricity Substations

1. Switchgear

The acoustic imaging camera efficiently detects partial discharge on switchgear cabinets via the inspection port. It aids personnel in confirming faults, minimizing downtime, and enhancing operational safety.

2. Wire

The acoustic imaging camera excels in detecting subtle partial discharge in 110kV cables, ensuring early detection of potential issues. Its advanced technology facilitates swift identification of weak points, empowering proactive maintenance.

3. High Voltage Room Insulator

Safety reigns supreme within high-voltage chambers. The handheld acoustic imaging camera provides a secure solution, enabling the precise detection of anomalies in insulators and equipment while maintaining safe distances. By leveraging this tool, risks to personnel are mitigated, and reliable power distribution is ensured.

4. Switch Insulator

Surface discharge incidents often occur on the porcelain pillars of switch cabinets. Acoustic imaging camera empower inspection teams to swiftly and precisely evaluate component performance, promptly identifying hazards.

Application Scene: Power Distribution System

1. Tower Insulator

The acoustic imaging camera remotely identifies abnormal discharges from distribution line insulators, facilitating early detection. Its precision ensures proactive mitigation of potential issues, enhancing grid reliability and safety.

2. Cable Distribution Box

Complex T-joints and busbar connections with high impedance are susceptible to discharge. Our acoustic imaging cameras simplify the identification of partial discharge, enabling precise localization and facilitating proactive maintenance to maximize grid stability and safety.

3. Drop Fuse

Defective fuses threaten system stability. CRYSOUND acoustic imaging camera promptly pinpoints partial discharge, facilitating prompt response.

4. Support Insulator

Continuous partial discharge in insulators erodes insulation properties. The height of support insulators hinders routine inspections. The CRYSOUND acoustic imaging camera enables safe, remote assessment, ensuring insulator integrity anduninterrupted power flow.

Partial discharge silently jeopardizes the safety and reliability of electrical systems. Rapid and precise identification of fault areas through acoustic imaging cameras is imperative for accident prevention and upholding the integrity of power systems. Leveraging the capabilities of acoustic imaging cameras guarantees the security and reliability of our electrical infrastructure.

For further information or to avail of our professional services, please do not hesitate to contact us. We are committed to providing effective solutions tailored to your needs!

System Devices

CRY2623 128-Mic Industrial Acoustic Imaging Camera

The CRY2623 is a 128-mic industrial acoustic imaging camera that is user-friendly and requires minimal training. Its durable aluminum alloy shell is built to withstand complex and variable working conditions. The device offers real-time acoustic imaging, significantly accelerating the detection of pressurized or vacuum leaks compared to traditional methods. It supports both photo and video modes for flexible on-site data recording. With an expandable large-capacity TF storage card, test results can be quickly exported and reported. The CRY2623 helps enterprises reduce safety risks and minimize economic losses associated with gas leaks, partial discharges, and other malfunctions.

CRY8124 Advanced Acoustic Imaging Camera

Introducing CRYSOUND’s cutting-edge acoustic imaging camera, revolutionizing industrial inspections with advanced capabilities. The CRY8124 acoustic imaging camera excels at pinpointing leaks, identifying electrical partial discharge, and detecting mechanical deterioration. Setting a new standard for sensitivity and efficiency, the CRY8124 boasts 200 microphones (the most in the industry). The device detects smaller leaks and partial discharges from greater distance than any other handheld acoustic imaging camera on the market.

The CRY8124 reporting software allows offline analysis, editing, and report generation, simplifying regular maintenance routines.

Elevate the effectiveness of your industrial inspections with CRYSOUND’s acoustic cameras.