January 19, 2026

Prepolarized vs. Externally Polarized Microphones

In acoustic testing, acoustic metrology, and product noise evaluation, the term measurement microphone typically refers to a condenser measurement microphone. Its signal generation relies on a polarization electric field: sound pressure changes the capacitance, and the front-end circuitry converts this change into an electrical signal.

Depending on how the polarization field is provided, measurement microphones generally fall into two categories: externally polarized (polarization high voltage supplied by the measurement system, typically 200 V) and prepolarized (an internal electret provides the equivalent polarization, so no external high voltage is needed). Both can deliver high-precision measurements; the key to selection is system compatibility, environmental constraints, and maintenance cost.

This article first explains how prepolarized and externally polarized microphones work and differ. It then compares power/front-end compatibility, noise and dynamic range, environmental robustness, and long-term stability. Next, it gives selection tips by scenario (metrology, approval tests, field, multichannel). It ends with a quick decision checklist.

System Requirements

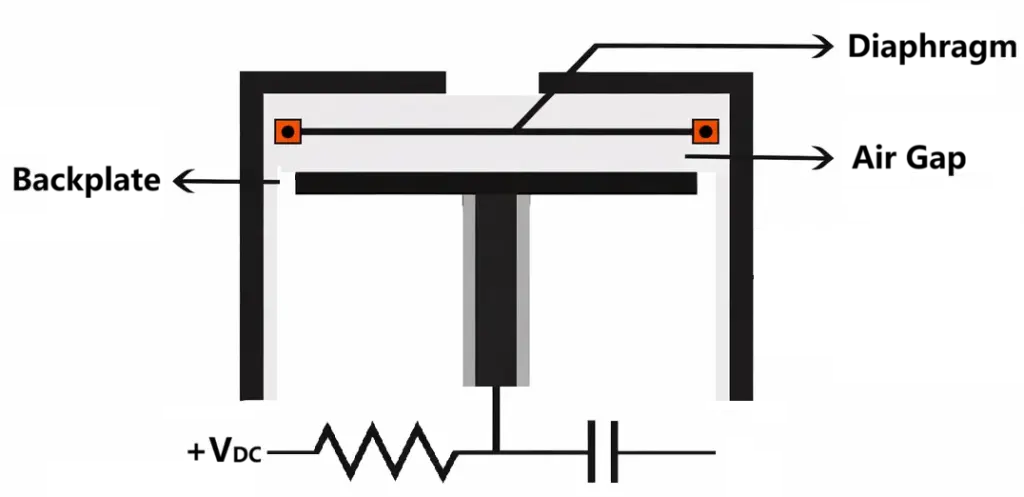

Externally Polarized

An externally polarized microphone requires a dedicated polarization unit / microphone power supply (provides 200 V polarization) to provide a stable polarization voltage (commonly 200 V) and to match the preamplifier interface (often 7-pin LEMO).

This signal chain is closer to traditional metrology setups and is commonly used in laboratories and traceable calibration scenarios.

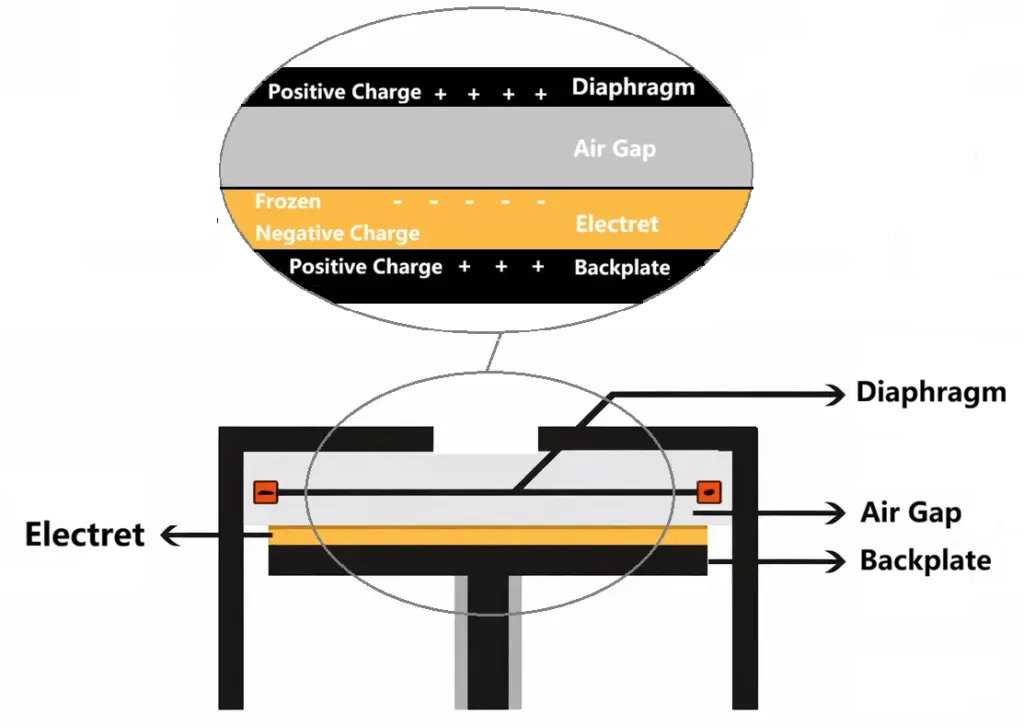

Prepolarized

A prepolarized microphone uses an internal electret to provide equivalent polarization, so no external polarization voltage is required.

System integration is simpler, making it well-suited for field work, mobile testing, and multi-channel distributed deployments. IEPE interfaces are widely used and broadly compatible; many data acquisition devices provide built-in IEPE inputs, which can significantly reduce overall equipment cost. (IEPE is the international term; some companies also refer to it as CCP or ICP.)

Engineering Trade-offs

From an engineering application perspective, the main differences are:

System compatibility: Externally polarized microphones depend on 200 V polarization and specific front-end/interfaces; prepolarized microphones place fewer requirements on the front-end and enable more flexible integration.

Environmental robustness: High humidity, condensation, dust, oil mist, and similar environments can amplify insulation and leakage issues; prepolarized microphones often achieve more stable results. For high-temperature applications, carefully verify the model’s temperature limit and long-term drift data; externally polarized microphones are more commonly used where high-temperature stability and metrology-grade requirements are prioritized.

Deployment and maintenance: Prepolarized solutions avoid high-voltage risk, deploy faster, and typically cost less at scale. Externally polarized setups demand higher standards for cleanliness, insulation, connector reliability, and troubleshooting capability.

Selection Guidelines

Front-End and Power Architecture

If your existing front-end natively supports 200 V polarization and you have long used that metrology signal chain, prioritize externally polarized microphones to minimize retrofit effort and compatibility risk.

If your front-end does not support polarization high voltage, or your system is mainly based on constant-current powering (e.g., CCLD/IEPE), prioritize prepolarized microphones for higher deployment efficiency and broader compatibility.

Environmental Constraints (Humidity / Contamination / Temperature)

For high humidity, condensation, dust, or oil mist in the field: prioritize prepolarized microphones or models with protective designs, and pay close attention to connector and cable protection.

For high temperature or thermal cycling: base the choice on datasheets and stability data. Both externally polarized and high-temperature prepolarized models may be suitable, but you must verify the temperature limit and drift specifications.

Align the Key Performance Targets

Low-noise measurement: focus on equivalent self-noise, front-end noise, cable length, and shielding/grounding strategy.

High SPL / shock measurement: focus on maximum SPL, distortion, overload recovery, and front-end input headroom (capsule size selection is often more critical than polarization method).

Consistency / traceability: focus on calibration system, long-term drift, temperature coefficient, and maintenance interval.

Budget and Total Cost of Ownership

If budget is tight, channel count is high, or you need rapid scaling: prioritize prepolarized microphones. Without external polarization high voltage, the measurement chain is simpler and total investment is usually lower.

If an externally polarized chain is required: include the external polarization power supply/adapter as a mandatory budget item. In addition to the microphone and preamplifier, a stable 200 V polarization supply is required, and the polarization supply can be costly. For multi-channel deployments, total cost rises significantly with channel count. If the laboratory already has sufficient channels of external polarization supplies, the incremental cost can be much lower.

Conclusion

There is no absolute “better” option between prepolarized and externally polarized microphones. A more reliable engineering approach is to first define the measurement chain and environmental constraints, then finalize the model selection using key metrics such as noise, dynamic range, consistency, and traceability.

You are welcome to learn more about microphone functions and hardware solutions on our website and use the “Get in touch” form to contact the CRYSOUND team.