November 28, 2025

The Complete Workflow from Sound Wave Acquisition to Acoustic Imaging

With the development of technology and industry, acoustic technology has become increasingly mature and is now widely used in areas ranging from consumer electronics to aerospace, and from medical facilities to scientific research. In various industrial inspection scenarios, equipment maintenance, and fault diagnosis, acoustic imaging has become a fast and convenient tool. It can transform sound waves that are difficult for the human ear to detect into intuitive images, helping technicians quickly locate problems.

CRYSOUND’s Acoustic Imaging products are designed for partial discharge detection, gas leak detection, mechanical fault detection, and more, and have been widely adopted in over ten industries, such as power distribution, automotive, and composites.

So, how exactly do acoustic imaging systems work? This blog will explain the complete workflow of an acoustic imaging system—from sound wave acquisition to visual imaging—in a simple and easy-to-understand way.

CRYSOUND Acoustic Imaging Camera Products

1. Sound Wave Acquisition: Capturing Invisible Sound Waves

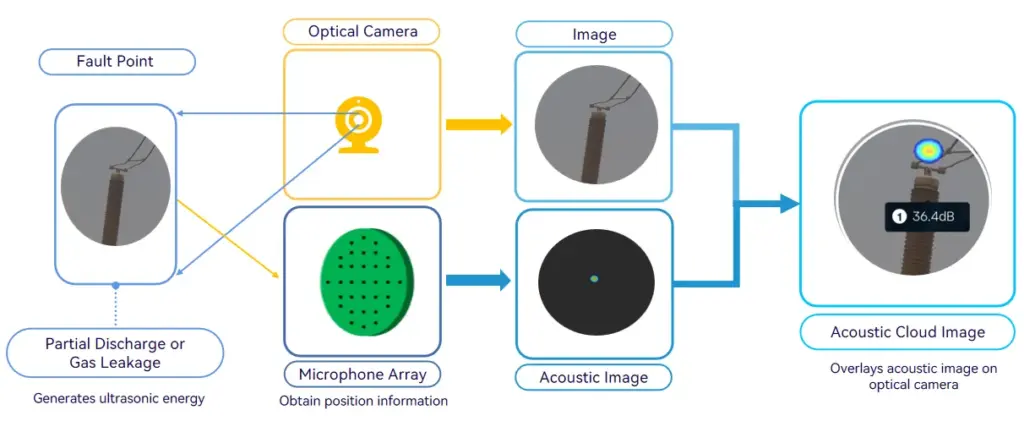

The core function of an acoustic imaging system is to capture sound waves, which are usually generated by vibrations, leaks, or malfunctions during equipment operation. When sound waves propagate through the air, they cause air molecules to vibrate, forming pressure waves. Acoustic imaging systems receive these pressure waves through a built-in microphone array (usually composed of multiple high-sensitivity microphones). Each microphone can independently capture the frequency, intensity, and phase information of the sound wave, like taking a ‘fingerprint’ of the sound.

For example, when a motor malfunctions, the wear of its internal bearings generates high-frequency vibrations. These vibrations propagate through the air and are captured by the microphone array of the acoustic imaging system. By analyzing these acoustic signals, technicians can initially determine the type and location of the fault.

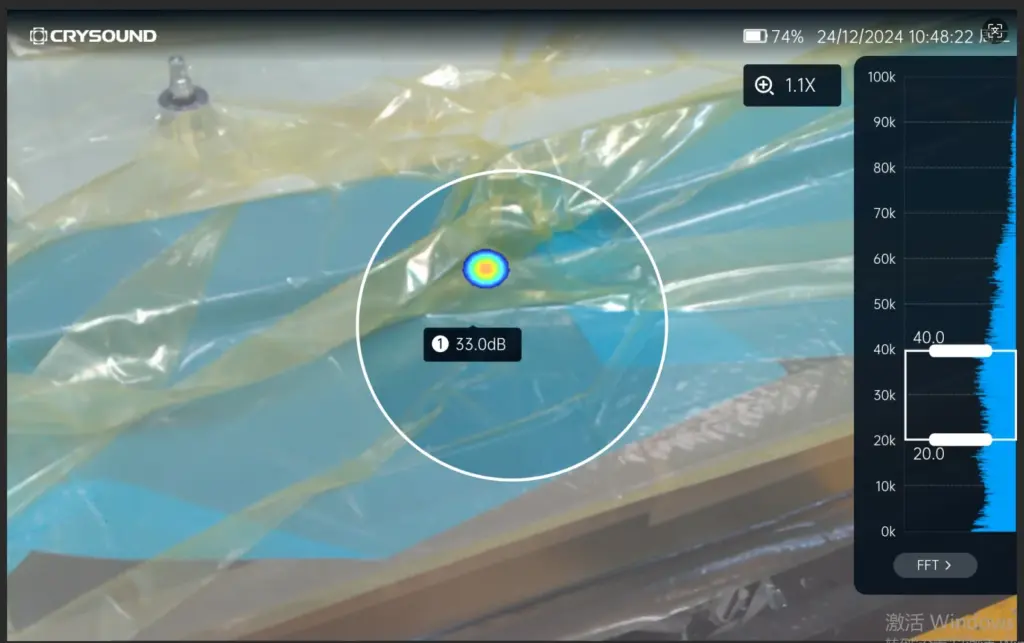

Gas Leak Detection

Mechanical Faults Detection

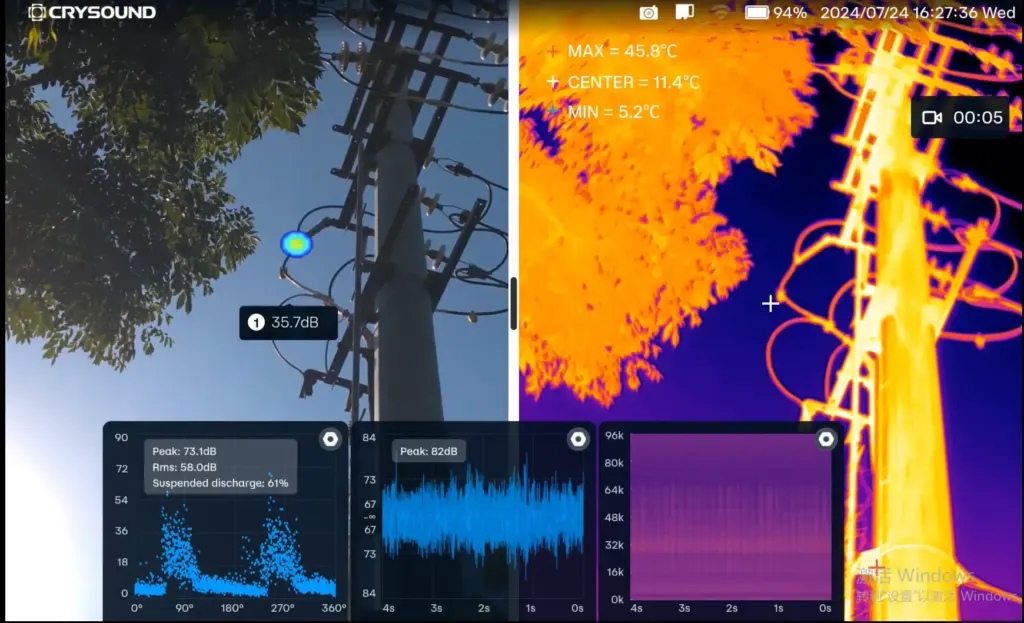

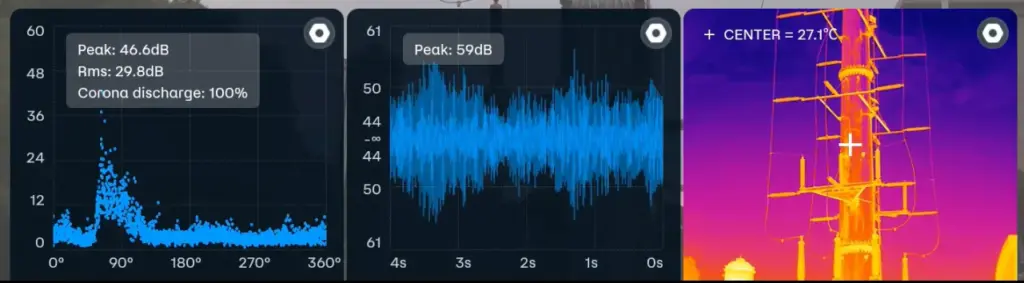

Partial Discharge Detection

2. Signal Processing: From Raw Data to Useful Information

The acquired acoustic signals are analog signals and need to be converted into digital signals by an analog-to-digital converter (ADC). These digital signals then enter the signal processing unit for a series of complex calculations. These calculations include:

Noise Reduction: Using digital filtering techniques, environmental noise and other interference signals are removed, retaining useful acoustic information.

Beamforming: Utilizing the spatial distribution of the microphone array, algorithms calculate the direction and distance of the sound source. This process is similar to using multiple ears to locate the sound source.

Spectrum Analysis: The acoustic signal is decomposed into components of different frequencies, and the intensity of each frequency component is analyzed to determine the nature of the sound source (e.g., mechanical faults, leaks, etc.).

After these processes, the raw acoustic signal is transformed into useful information containing the sound source’s location, intensity, and frequency characteristics.

3. Visual Imaging: Converting Sound into Images

The processed acoustic data needs to be presented to the user in an intuitive way. Acoustic imaging cameras visualize sound through the following steps:

Data Mapping: Mapping the location information of the sound source onto two-dimensional or three-dimensional space to form a sound source distribution map. Typically, an acoustic imaging camera uses color to represent sound wave intensity: red or yellow indicates a strong sound source, and blue or green indicates a weak sound source.

Image Overlay: Overlaying the sound source distribution map with a visible-light image or infrared image to form a composite image. This allows users to see the physical appearance of the equipment and the distribution of sound sources on the same image, thus quickly locating problem areas.

Real-time Display: Acoustic imaging cameras typically provide real-time imaging capabilities, dynamically displaying changes in sound sources. This is extremely useful for monitoring equipment operating status and diagnosing faults.

4. Application Scenarios: A Wide Range of Uses

The working principle of acoustic imaging makes it widely applicable in multiple fields. In the industrial field, acoustic imaging cameras can be used to detect mechanical faults, gas leaks, and electrical problems in equipment. For example, by analyzing the sound waves of a transformer during operation, it is possible to determine whether there is internal discharge or loosening.

5. Technical Advantages: High Efficiency, Precision, and Non-Contact

The working principle of acoustic imaging systems gives them the following technical advantages:

High Efficiency: Acoustic imaging cameras can quickly scan large areas and display the distribution of sound sources in real time, greatly improving detection efficiency.

Precision: Through advanced signal processing algorithms, acoustic imaging cameras can accurately locate the position and intensity of sound sources, with errors typically within a few centimeters.

Non-Contact: Acoustic imaging cameras do not require contact with the device under test, avoiding potential damage or interference from traditional detection methods.

Conclusion

Acoustic imaging systems transform invisible sound into intuitive images by capturing sound waves, processing signals, and visualizing images, providing a powerful tool for fault diagnosis and equipment maintenance. Although their working principle involves complex signal processing algorithms, the core logic is simple and easy to understand: from sound wave acquisition to visual imaging, every step is aimed at converting sound into useful information. With the continuous development of technology, acoustic imaging technology will continue to demonstrate its unique value in more fields.

If you are interested in CRYSOUND’s acoustic imaging solutions or would like to discuss your specific application, please fill out the ‘Get in touch’ form below and our team will be happy to assist you.