January 13, 2026

Why Measurement Microphones Are Made in Cleanrooms

Measurement microphones are used in acoustic metrology, type-approval testing, and engineering measurements. Unlike general audio capture applications, measurement scenarios place far greater emphasis on consistency and traceability: the same microphone should deliver stable output when re-tested over time; variation within a production lot should be sufficiently small; and performance fluctuations between lots should remain controllable.

In these applications, tiny contaminants introduced during manufacturing may not cause immediate “failure,” but can accumulate over time as increased self-noise, subtle shifts in frequency response, changes in insulation leakage, or long-term drift—ultimately increasing measurement uncertainty and recalibration costs. Therefore, completing critical component assembly and sealing steps inside a controlled clean environment (a cleanroom) is a common engineering approach to achieve stable performance and batch-to-batch consistency for measurement-grade microphones.

This article starts with measurement microphone structures and traceability requirements, then explains how particulate and molecular contamination affects noise, response, and drift. It next outlines cleanroom controls (cleanliness class, environment, people/material flow) that reduce risk. Finally, it summarizes benefits for consistency and recalibration cost.

Critical Structure and Measurement-Grade Requirements

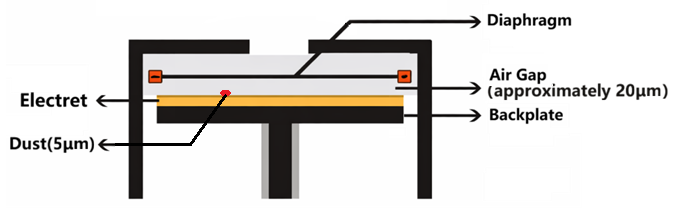

Taking a condenser measurement microphone as an example, its core structure consists of the diaphragm, backplate, an extremely small gap, and acoustic pathways. The dimensions and surface conditions of these structures directly affect sensitivity, frequency response, phase characteristics, and self-noise.

Measurement microphones typically need to meet standardized geometric and electroacoustic requirements and support a traceable calibration chain. For example, the IEC 61094 series specifies requirements related to measurement microphone specifications and calibration, helping ensure comparability and consistency when used as metrology instruments and transfer standards.

How Contamination Affects Performance

Contamination typically falls into two categories: particulate contamination (dust, fibers, skin flakes, metal debris, etc.) and molecular contamination (oil mist, residual volatile organic compounds, cleaning-agent residues, etc.). For measurement microphones, both can alter boundary conditions of diaphragm motion, acoustic damping, or electrical insulation.

Particulate Contamination: Self-Noise, Nonlinearity, and Response Deviation

When particles enter critical gaps or adhere near the diaphragm, they may introduce localized friction and changes in damping, raising self-noise and reducing the effective dynamic range for low-level measurements. In more extreme cases, particles can cause intermittent contact or restricted motion, resulting in nonlinear distortion and poorer repeatability.

Molecular Contamination: Changes in Insulation and Charge Stability

Molecular contamination often appears as thin-film deposits on surfaces. Such films may change surface resistance on insulating parts, altering leakage currents and therefore affecting effective polarization conditions and low-frequency stability, potentially increasing electrical noise. For measurement chains requiring long-term stability, issues caused by molecular contamination are more subtle and often manifest as slow drift.

Moisture Absorption/Migration and Batch Variation: Long-Term Stability and Consistency

Some contaminants are hygroscopic or migratory. Under temperature and humidity cycling and long-term aging, their distribution and surface state may keep changing, causing gradual drift in sensitivity and frequency response. Meanwhile, contamination events are inherently random: the location and amount of particle deposition are hard to reproduce, which can amplify within-lot dispersion and lead to yield fluctuations—ultimately increasing the workload for system-level calibration and consistency control.

The Engineering Value of a Cleanroom: Bringing “Contamination Risk” Under Process Control

A cleanroom keeps particulate and molecular contamination within a verifiable range and stabilizes environmental parameters such as temperature, humidity, and pressure differential. Cleanroom classification commonly references ISO 14644-1, which uses airborne particle concentration as the primary metric. For measurement microphones, the key is to bring contamination risk in assembly, sealing, and packaging steps under process control.

- Completing critical assembly and sealing in a low-particle environment reduces the likelihood of random dust and fiber contamination.

- Controlling temperature/humidity, pressure differential, and implementing electrostatic management reduces risks from adsorption and secondary deposition.

- Following standardized protocols for personnel/material entry and tool maintenance—and maintaining clean packaging—helps preserve a consistent “as-shipped” condition.

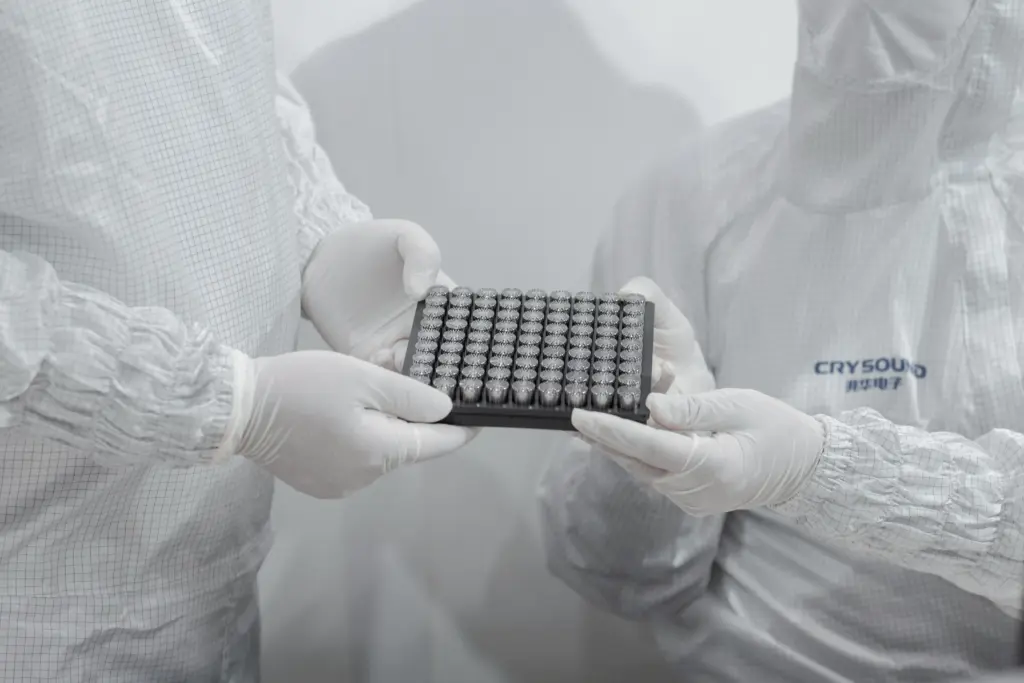

At CRYSOUND, critical assembly and sealing are performed in a Class 1,000 cleanroom, equivalent to ISO Class 6 under ISO 14644-1. It helps reduce particulate contamination risk during mass production while keeping process conditions stable.

Cleanrooms and Calibration: Complementary, Not a Substitute

A cleanroom controls contamination variables during manufacturing to reduce the risks of performance dispersion and drift. Calibration establishes traceability and provides parameters such as sensitivity under specified conditions. Clean manufacturing cannot replace calibration, but it can improve re-test consistency and reduce the impact of drift on calibration intervals and uncertainty.

Direct Value for End Applications

Once contamination variables are controlled, self-noise levels and response characteristics become more stable, and batch-to-batch differences are easier to manage. In multi-channel systems, acoustic imaging measurements, and production-line consistency monitoring, sensor interchangeability is easier to achieve—and it also becomes easier to define more appropriate recalibration and periodic verification strategies.

A clean, controlled environment provides stable contamination control conditions for key manufacturing steps of measurement microphones, helping reduce risks of elevated self-noise, response deviation, and long-term drift. Combined with standardized design, in-process inspection, and traceable calibration, reliable measurement results can be maintained throughout the product lifecycle.

You are welcome to learn more about microphone functions and hardware solutions on our website and use the“Get in touch”form to contact the CRYSOUND team.