November 28, 2025

Endless Silence for Motors: CRYSOUND’s Intelligent BSR Detection Solution

Electric motors are widely used in modern automobiles and home appliances (such as in-vehicle electric seats and appliance fans), and their smooth operation directly affects product quality and user experience. Motor noise issues are often summarized as BSR (Buzz, Squeak, and Rattle), which refers to abnormal sounds generated by automotive motors and related components. BSR has been a long-standing issue in manufacturing. It not only lowers the perceived quality of the product but also may signal problems such as bearing wear, loose parts, and other faults. Allowing defective products to reach the market can seriously damage brand reputation and user experience.

Traditional “Manual Listening”: Painful and Unreliable

In the past, BSR detection usually relied on “manual listening,” but human hearing has significant limitations:

- Subjective Misjudgment: When BSR noise is masked by background noise, the human ear cannot easily identify it. Judgments are based on experience, and results lack objective support.

- Unable to Quantify Analysis: The severity of BSR is difficult to quantify, making it difficult to establish clear quality standards.

- Low Efficiency and Fatigue: After prolonged testing, the human ear becomes fatigued, and detection accuracy declines, increasing the risk of defective products slipping through.

Breaking the Bottleneck: Intelligent Solutions to Overcome Manual Limitations

CRYSOUND, deeply rooted in the field of acoustic testing, has launched a BSR-based end-of-line (EoL) acoustic test solution for electric motors. By combining hardware, software, and AI, CRYSOUND has created a closed-loop testing process that gives motor abnormal sound detection an intelligent upgrade.

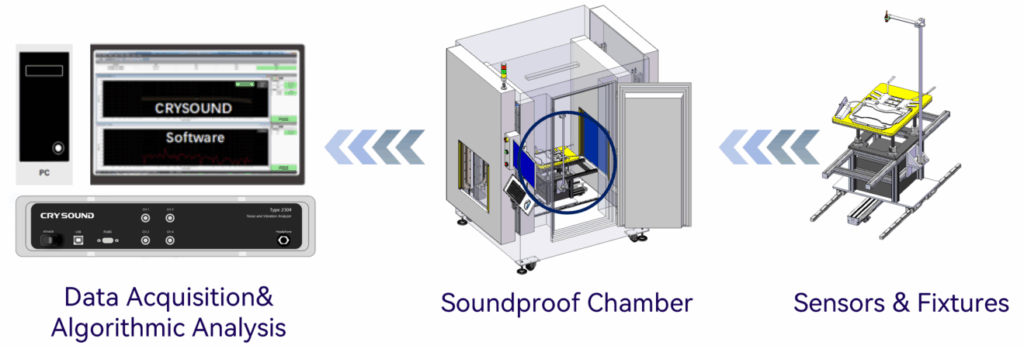

Core Components: BSR Detection Hardware System + Testing Software Platform

- Soundproof Chamber: Creates a controlled, low-noise testing environment, blocking external noise that could disrupt BSR detection.

- Data Acquisition Module: Accurately captures sound and vibration data from the motor during operation, ensuring that even subtle anomalies are not overlooked.

- Algorithm Analysis: Processes, analyzes, and intelligently evaluates the captured signals, making BSR defects difficult to hide.

Test Workflow: From Signal Capture to Intelligent Decision

1. First, sensors precisely capture sound and vibration signals, converting the sound of the motor into digital data.

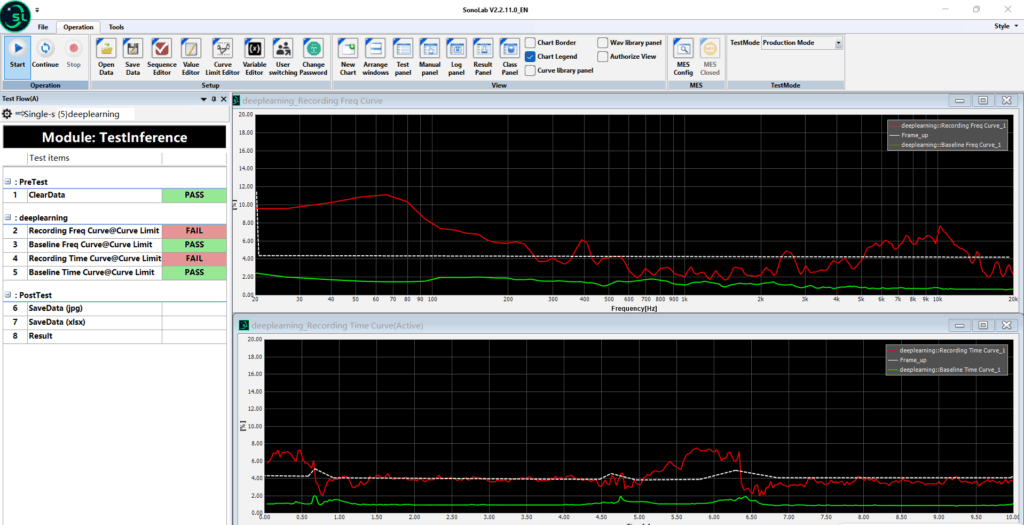

2. Then, the system processes the data and automatically generates visual analysis results, clearly showing where abnormalities occur and how severe they are.

3. Finally, professional algorithms such as transient analysis, FFT spectrum analysis, and sound-quality evaluation are applied. With deep learning models, the system can automatically identify BSR caused by bearing wear, looseness, foreign-object interference, and other factors, greatly reducing human misjudgment and accurately separating good products from defective ones.

Multi-Scenario Coverage: From Motors to High-End Manufacturing, Boosting Quality Control Across Industries

This solution has been widely applied in the following areas:

- Motor Assemblies: BSR detection for various micro motors, drive motors, actuators, and other motor-related components.

- Automotive Parts: In the body domain—air-conditioning vents, seat systems/rails/motors, electric door handles, and other components; in the cockpit domain—HUD motors, display rotation mechanisms, electric sunroofs, and related parts; in the chassis domain—braking systems, steering systems, and associated components; in the autonomous driving domain—LiDAR modules and other systems requiring BSR evaluation.

- Home Appliances: BSR detection for motors and motorized components used in high-end household appliances and smart home devices.

- Others: Industrial scenarios requiring stringent sound quality assessment and high-precision BSR detection.

Five Major Advantages: Making Quality Inspection Smarter

- AI Acoustic Detection: By replacing manual inspection with machines, detection becomes more objective and efficient and supports continuous, high-throughput operation in production environments.

- Accurate BSR Capture and Visual Presentation: The characteristics of BSR are visually displayed through data charts, making problems easy to identify at a glance.

- Supports Full EoL Testing, Traceable Results: All process data is retained, making quality traceability clear and compliant with regulations.

- Highly Integrated One-Stop Solution, Improved Production Efficiency: This highly integrated, one-stop solution streamlines the testing process and seamlessly connects to the production line, enhancing overall production efficiency.

- Helps Improve Yield and Reduce Customer Complaints: Ensures strict quality control, making it difficult for defective products to leave the factory and significantly reducing customer complaints.

If you are interested in CRYSOUND’s intelligent BSR noise detection solution or would like to discuss your specific testing needs, please fill out the “Get in touch” form below and our team will be happy to assist you.