Measure Sound Better

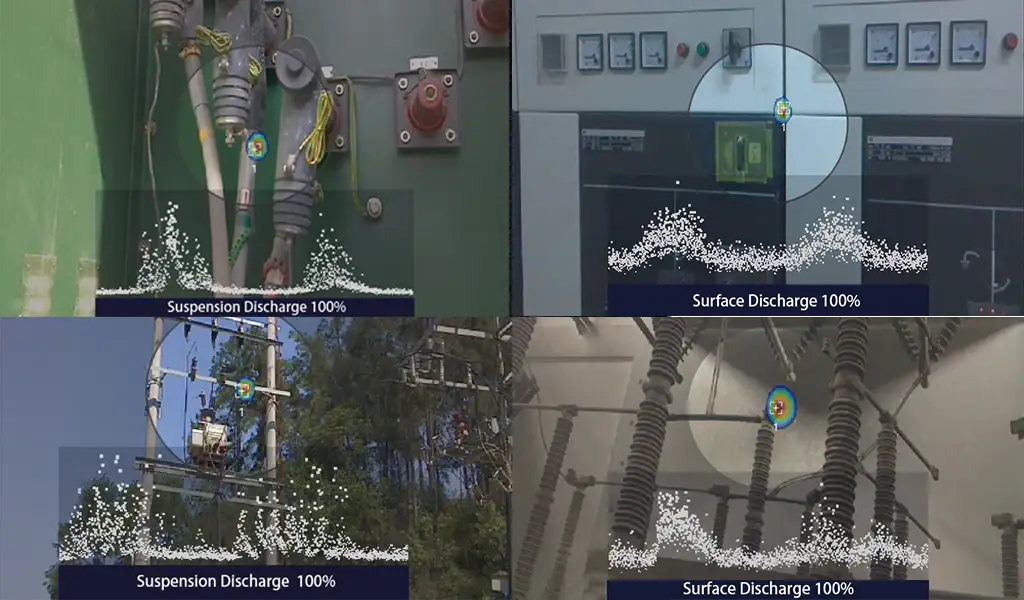

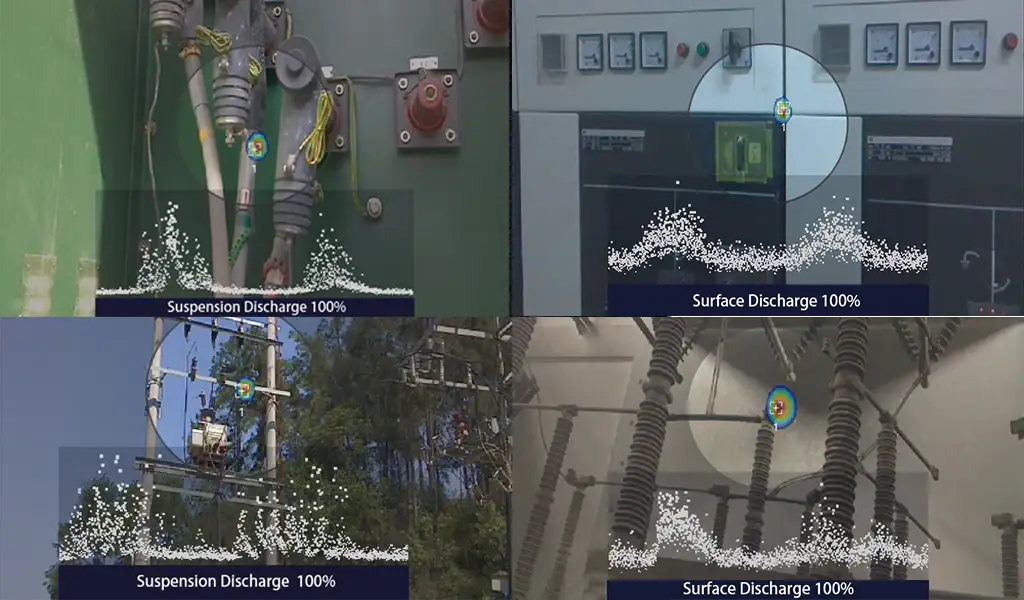

PD Detection in Common Scenarios

Identify PD at a Glance

Locate PD in real-time

As the camera scans the area, it instantly visualizes the location of PD on the screen.

Works for all PD types

Inspection teams can quickly and accurately assess the operation of switch cabinet components using acoustic imaging camera, thereby identifying safety hazards in a timely manner.

Safety operation requirements applicable to various scenarios

Electricity Substations

In substation scenarios, the Acoustic Imaging Camera can efficiently monitor the operation of switchgear, cables, high-voltage chamber porcelain vases, switch insulators, and other equipment while also investigating potential safety hazards.

Distribution system

Distribution lines transport energy to any location that requires electricity, resulting in long and complex distribution lines. The Acoustic Imaging Camera provide ultra-long-distance detection capabilities, allowing inspectors to readily detect numerous equipment on towers from a comfortable distance, ensuring the power system's safe operation.

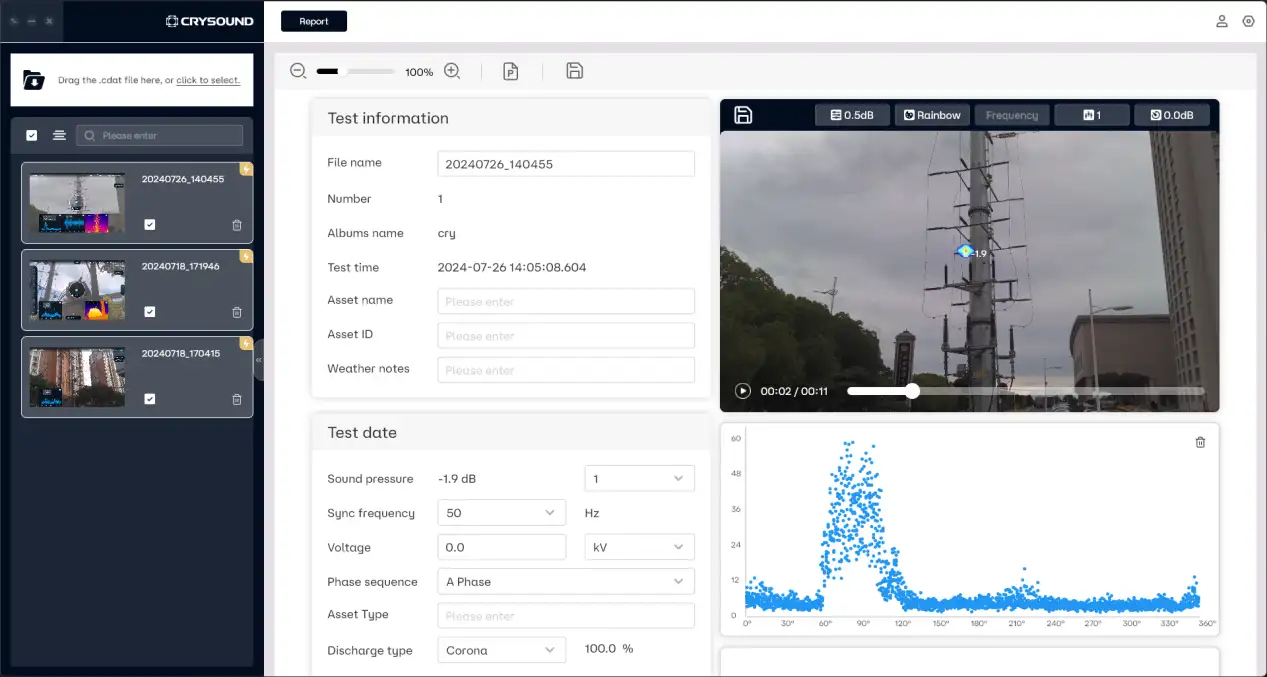

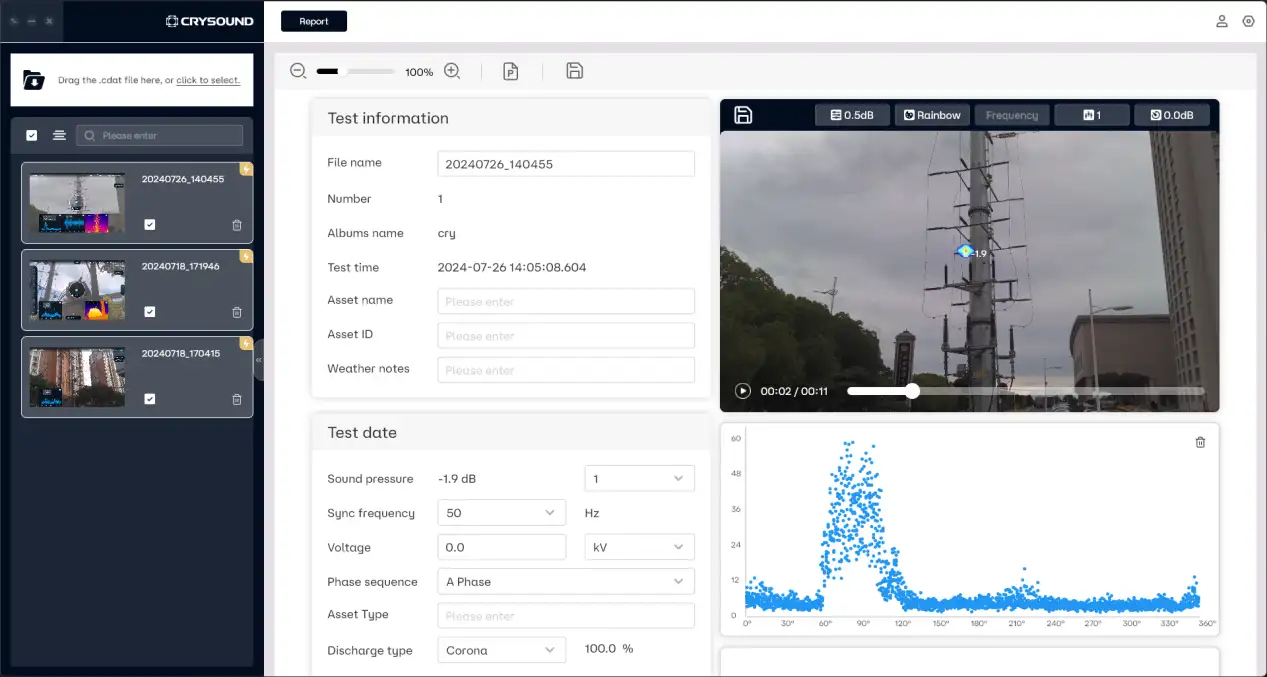

Listening + PRPD mapping to get more accurate localized discharge type determination

More accurate judgment

The method of listening and mapping can improve the accuracy of the fault identification.

Eliminate the interference of irrelevant sound sources

PRPD mapping can clearly determine the type of sound source.

Minimal Training Requirements

Intuitive display

The screen of the acoustic camera presents vivid images with a touchscreen interface.

No experts needed

The device is user-friendly, requiring little training to operate.

Measuring the extent of PD

See the extent of PD

Based on the measured dB SPL value, the acoustic camera calculates the leak rate and economic loss of each leak

Streamline the reporting process

Using reporting tools, data can be shared between teams to prioritize repairs and optimize resource allocation

System Devices

CRY8124 Advanced Acoustic Imaging Camera

Explore More Cases

Get in touch

If you are interested or have questions about our products, book a demo and we will be glad to show how it works, which solutions it can take part of and discuss how it might fit your needs and organization.